On-Time Order Shipments & Delivery

2025 - WEEK 15; 97%

Cutting flexible materials with industrial razor blades requires a blade holder. On this page you will find the options we offer: mechanical holder, pneumatic holder and heated pneumatic holder. The range of industrial blades can be found here.

Worldwide shipping. Orders for in-stock items placed before 1pm will normally be dispatched the same day. For more details, please see the "Terms of Purchase and Delivery" page or contact us at order@sollex.se.

Razor slitting is a method for cutting thin and flexible materials into narrow strips in slitter machines. Each industrial slitting blade sits in separate holders which are placed on a shaft. The number of blade holders depends on the number of strips to be cut and rolled up. Razor blade slitting of material is most often done along the flow of the material that is why it is called slitting.

Industrial razor blade slitting method is often used for high-speed cutting of flexible materials and is popular with manufacturers for converting packaging all kind of plastic films, aluminum foil and non-wovens. This cutting technique can be performed either during material production in a slitter-rewinder in-line or as a separate step in an automatic rewinder machine. Slitting material in-line is probably the most complex slitting operation you can have. More about razor slitting read here.

All industrial slitting razor blades are installed in a suitable blade holder. In addition, the correct choice of industrial blades and holders plays an important role in the final quality of the product and the cut. That is why it is so important to analyze all factors and find the right solution for your application.

Blade holders have different designs depending on the slitter in which they are placed, the blades and the quantity of blades to be inserted into them, the shaft diameter, the material to be cut, cutting angle and more.

Blade holders have different designs depending on the slitter in which they are placed, the blades and the quantity of blades to be inserted into them, the shaft diameter, the material to be cut, cutting angle and more.

We offer you 3 types of blade holders that have slight differences but are also characterized by these features:

The mechanical holder 470561 is the simplest variant of holders, which is attached to the shaft manually with a clamping lever. The blade is changed using flat-tipped pliers. On the mechanical holder, the blade is fixed by a spring on one side and a magnet on the other, the blade itself has an end position, which is limited by a pin.

Pneumatical razor blade holder 470411 - an improved version of the manual blade holder. It differs in that the blades can be changed without tools. The blade (without pressure) is completely hidden in the holder for maximum safety. Single and double cuts are possible with a minimum distance of 10 mm from the center of the blade to the center of the blade.

Security is the main advantage of the pneumatical blade holders for razor slitting, when the machine stops the blade goes back into the holder and is fully covered.

In this heated blade holder variant, heated cutting is performed, which is recommended for cutting some materials such as fabric or woven material, as there is a melting effect to reduce fibers after cutting. Very thick plastic material can be cut more easily, not used for paper and film with low melting point. Heated holder 470421 used with temperature controller for heated knife holder - 470422

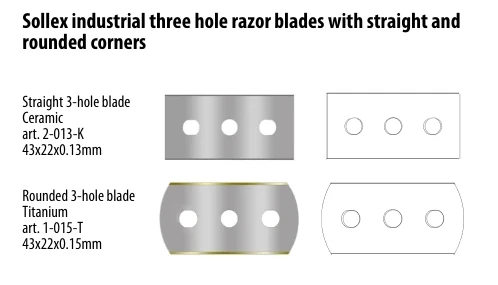

The blade holders which is presented on our website can hold straight razor blades and razor blades with rounded edges of size 43*22mm. The thickness of blades is not essential for the use of these holders, but for example, at SOLLEX you can find industrial blades of the following thicknesses: 0.13mm, 0.15mm, 0.20mm, 0.30mm, 0.40mm.

The blade holders which is presented on our website can hold straight razor blades and razor blades with rounded edges of size 43*22mm. The thickness of blades is not essential for the use of these holders, but for example, at SOLLEX you can find industrial blades of the following thicknesses: 0.13mm, 0.15mm, 0.20mm, 0.30mm, 0.40mm.

In general, the blade holders are different and the design is adapted to the material to be produced and cut, the productivity and output of the product, the types of blades installed in them, the cutting angle and much more. If you need more information, please contact us for help.

Sollex offers high-quality industrial slitting razor blades to convert and slit the common types of plastic film:

Sollex offers high quality industrial razor blades to manufacturers of plastic film, foil, and flexible packaging. Our industrial razor blades are made of high chrome carbon steel with oxide layers to protect the blade from rusting.

Sollex industrial knife blades are available in the following materials and coatings: tool steel, stainless steel, carbon steel, hard tungsten carbide, T - titanium nitride TiN coating, Z - zero friction, K - ceramic coating, X - full ceramic coating.

Sollex manufactures knives from high quality Swedish and German steel. In addition to steel knives, we also have hard tungsten carbide knives in our range. Read more about coating for industrial razor blades here

Most of Sollex industrial razor blades are supplied in so-called partner packaging. The packaging is very convenient for industrial applications. The razor blades lie on top of each other on two spears in the plastic packaging. The edges of the cutting blades are not in contact with the packaging.

Razor cutting produces very precise cuts with minimal waste. The blade can be positioned at a specific angle to produce the desired cut for greater precision.

Razor cutting produces very precise cuts with minimal waste. The blade can be positioned at a specific angle to produce the desired cut for greater precision.

Razor slitting is a high-speed cutting method that allows for a large volume of material to be cut quickly and efficiently. Because razor blades are very sharp, they produce very few burrs or nicks, which reduces the amount of post-cut processing.

Razor blade cutting systems are used in converting machines like slitters for cutting film, foil, laminated materials, non-woven, textiles and mesh. Nevertheless, the razor slitting method is not optimized to cut rigid, heavy or extremely abrasive materials.

Blades will need frequent replacement due to wear. It is therefore necessary to always have a good stock of blades for continuous production. It is also important to be able to change blades without stopping the cutter, so the blade holder should be designed with this in mind. Blade wear depends on the material being cut, additives and masterbatches, layers, cutting speed, cutting angle and more.

Razor blades are mounted at an angle in holders to cut a moving blade. The angle of the blade is very important as it affects the quality of the cut. Aim to keep the cutting angle at 45 degrees, which will give you the best outcome in most cases.

The resulting cut also depends on the characteristics of the material. These include thickness, density, stiffness, ductility, coating and other factors.

Improperly selected razor blades can generate enough heat to melt film or other material, create beads, which negatively affects getting good roll edges. Read more about the 13 cutting problems most commonly experienced by manufacturers of flexible materials here.

Sollex offers its customers a wide range of razor blades for various industrial applications, complementing the offer with blade holders. Contact Sollex if you want to find the best blades for industrial cutting, improve the quality of your current output and reduce defects and spoilage in your manufacturing process.

Standard knives that are in stock will be shipped the same day if an order is placed before 1 pm on weekdays. Within Sweden, delivery takes one to two business days with Schenker. Two to five working days inside Europe with UPS. Our goal is always to deliver to your address as quickly as possible.

You will be given a delivery time, which typically ranges from 4 to 9 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

All first orders from new customers are prepaid. Further orders can be paid by invoice with 30 days payment term.

Once your order is confirmed and shipped, you will receive a tracking number, which you can track.

Sollex primarily sells machine knives of standard size and form that comply with the EOM. Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

We do, however, create bespoke knives of non-standard size and shape when a drawing or explicit request is provided. For example, we can manufacture solid tungsten carbide machine knives in a variety of non-standard forms with ultra-precise and extreme tolerances, which is very useful in the MedTech industry.

When contacting a knife manufacturer to order knives for machines and slitters, providing accurate inquiries and detailed information is critical to ensure you receive industrial knives that meet the needs of your slitting, converting operations and the material you will be cutting.

If you are ordering custom machine knives from Sollex, make sure you know the exact knife dimensions, material and mounting specifications. A drawing and a worn sample for analysis are useful. If not available a photo with clear dimensions can work. Identify in your request the current cutting problems you are currently experiencing with the cutting knife you are seeking to replace. If in doubt, our experts can help you find the right knife based on your machine model and cutting needs.

To help you pick the best blade, Sollex may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

Actually, our clients and industry partners often place recurrent orders for industrial knives with predetermined delivery dates. We ensure your production process runs well by manufacturing and delivering machine knives and blades on schedule. The most important thing is to tell us the volume of required knives and deadlines and we will prepare a warehouse supply guarantee.

Sollex sales may technical assistance and guidance on choosing a slitting knife in addition to assessing and creating the best cutting solution for your application. You can consult via phone, mail, or video conference. To do this, send an email to order@sollex.se.

Read our policy on returns and claims on the “Complaint & Return” page.

There are a number of ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. Read about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance here.

JavaScript seem to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.