Slitting Blades for Bandera Extrusion Lines

We have scalpel handles, including scalpel handles from the manufacturer Swann Morton, as well as pen knives ( pens with blade ) for both surgical use and crafts. Learn in our blog article how to use a scalpel safely, how to hold it properly in your hand, and how to change the blade and many more.

Scalpel and craft blades for scalpels can be found here.

Worldwide shipping. Orders for in-stock items placed before 1pm will normally be dispatched the same day. For more details, please see the "Terms of Purchase and Delivery" page. If you can't find what you're looking for you're very welcome to get in touch with us at +46 35-157500 or info@sollex.se.

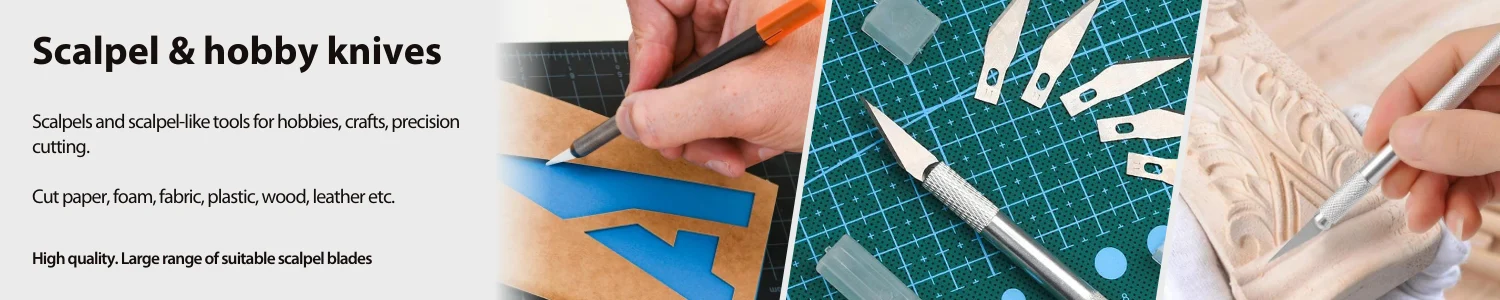

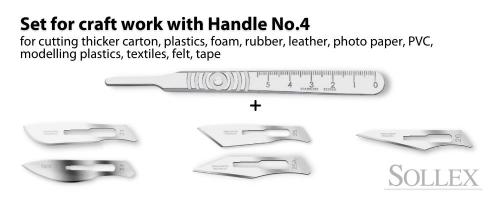

There are various cutting hand tools used for precise and detailed cutting for hobby projects, design, carving, etc. There are many English names that you can find on the internet that all mean about the same scalpel-like tool: precise craft knife, precision knife, hobby knife, craft knife, carving knife, hobby scalpel etc. These are scalpel-like cutting tools which are the perfect tools for designers, artists, and model makers for cutting materials such as cardboard, paper, wallpaper, plastic, textiles, leather, graphic design, gently deburring plastic parts and all kinds of precision cutting.

There are various cutting hand tools used for precise and detailed cutting for hobby projects, design, carving, etc. There are many English names that you can find on the internet that all mean about the same scalpel-like tool: precise craft knife, precision knife, hobby knife, craft knife, carving knife, hobby scalpel etc. These are scalpel-like cutting tools which are the perfect tools for designers, artists, and model makers for cutting materials such as cardboard, paper, wallpaper, plastic, textiles, leather, graphic design, gently deburring plastic parts and all kinds of precision cutting.

Hobby scalpels and precision pen knives are used to cut a variety of materials, depending on the specific application.

Paper: Precision knives are often used to cut paper in crafts such as scrapbooking, card-making, and papercraft.

Cardboard: Scalpels and precision knives can be used to cut cardboard for model-making, packaging, and other applications.

Cardboard: Scalpels and precision knives can be used to cut cardboard for model-making, packaging, and other applications.

Foam: Scalpels and pen knives are commonly used to cut foam, such as Styrofoam, for model-making and other craft applications.

Fabric: Precision knives and scalpels can be used to cut fabric for sewing and quilting projects.

Plastic: Scalpels and precision knives can be used to cut thin sheets of plastic for model-making and other applications.

Wood: Hobby scalpels and precision knives can be used to cut and carve small pieces of wood for model-making, woodworking, and other craft applications.

Crafting professionals know the importance of replacing their scalpel blades regularly, rather than waiting for them to break or chip. Dull scalpel blades can hinder your creativity and lead to subpar results.A fresh blade allows for ultra-precision, enabling you to make clean cuts that set your work apart.The frequency of blade replacement when crafting depends on several factors, such as the material being cut, the amount of use, and the level of precision required for the task at hand.But if you hear a specific sound while cutting, for example, a carton, it is time to replace the blade. It is advisable not to spare the blade, because a blunt blade can begin to tear the cutting material and the ends of the cut will be torn and sloppy.

Crafting professionals know the importance of replacing their scalpel blades regularly, rather than waiting for them to break or chip. Dull scalpel blades can hinder your creativity and lead to subpar results.A fresh blade allows for ultra-precision, enabling you to make clean cuts that set your work apart.The frequency of blade replacement when crafting depends on several factors, such as the material being cut, the amount of use, and the level of precision required for the task at hand.But if you hear a specific sound while cutting, for example, a carton, it is time to replace the blade. It is advisable not to spare the blade, because a blunt blade can begin to tear the cutting material and the ends of the cut will be torn and sloppy.

Dermaplaning is a cosmetic procedure used to remove facial hair and dead skin cells from the skin's surface, leaving it smoother and more radiant. Swann-Morton Scalpel Handles and Blades are a popular choice among trained aestheticians and estheticians for performing dermaplaning treatments.

For a dermaplaning procedure, are used the Swann Morton 10R scalpel blade with Swann-Morton No.3 scalpel handle. In addition, we recommend having a blade removal tool, such as pliers, and a blade disposal box, such as the Sollex 988 Safety Box.

One of the main advantages of the 10R blade is its ability to access more restricted areas of the skin and face, providing precision in delicate areas. Additionally, the rounded nose of the blade reduces the chance of accidental nicks to the skin, providing a safer and more consistent experience for the user.

Swann-Morton scalpel handles and blades are made of durable stainless steel. Scalpel handles can be reused multiple times, making them a cost-effective option. Moreover, Swann-Morton Scalpel Handles and Blades are a reliable and efficient tool for performing professional-grade dermaplaning treatments, and are commonly used by trained professionals in a clinical setting.

We carefully select goods in our range and always guarantee quality and reasonable prices. If you need quality blades and knife handles for hobby, craft and detail work, then you've come to the right store. If you have any questions, please contact our customer service

Standard knives that are in stock will be shipped the same day if an order is placed before 1 pm on weekdays. Within Sweden, delivery takes one to two business days with Schenker. Two to five working days inside Europe with UPS. Our goal is always to deliver to your address as quickly as possible.

You will be given a delivery time, which typically ranges from 4 to 9 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

All first orders from new customers are prepaid. Further orders can be paid by invoice with 30 days payment term.

Once your order is confirmed and shipped, you will receive a tracking number, which you can track.

Sollex primarily sells machine knives of standard size and form that comply with the EOM. Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

We do, however, create bespoke knives of non-standard size and shape when a drawing or explicit request is provided. For example, we can manufacture solid tungsten carbide machine knives in a variety of non-standard forms with ultra-precise and extreme tolerances, which is very useful in the MedTech industry.

When contacting a knife manufacturer to order knives for machines and slitters, providing accurate inquiries and detailed information is critical to ensure you receive industrial knives that meet the needs of your slitting, converting operations and the material you will be cutting.

If you are ordering custom machine knives from Sollex, make sure you know the exact knife dimensions, material and mounting specifications. A drawing and a worn sample for analysis are useful. If not available a photo with clear dimensions can work. Identify in your request the current cutting problems you are currently experiencing with the cutting knife you are seeking to replace. If in doubt, our experts can help you find the right knife based on your machine model and cutting needs.

To help you pick the best blade, Sollex may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

Actually, our clients and industry partners often place recurrent orders for industrial knives with predetermined delivery dates. We ensure your production process runs well by manufacturing and delivering machine knives and blades on schedule. The most important thing is to tell us the volume of required knives and deadlines and we will prepare a warehouse supply guarantee.

Sollex sales may technical assistance and guidance on choosing a slitting knife in addition to assessing and creating the best cutting solution for your application. You can consult via phone, mail, or video conference. To do this, send an email to order@sollex.se.

Read our policy on returns and claims on the “Complaint & Return” page.

There are a number of ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. Read about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance here.

JavaScript seem to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.