6 Key Trends Shaping Cutting Technology in 2025

Sollex supply both straight and circular toothed blades and perforation knives for packaging machines. Not all knives are online but we keep many in stock. So if you need serrated blades for cutting flexible packaging, adhesive tape, plastic film, poly-tube bags, foil, paper and composite in various material combinations write to us and we will find find the best solution adapted to your needs. Various shapes and sizes of packaging knives produced according to your drawings or samples.

Worldwide shipping. Orders for in-stock items placed before 1pm will normally be dispatched the same day. For more details, please see the "Terms of Purchase and Delivery" page. If you can't find what you're looking for you're very welcome to get in touch with us at +46 35-157500 or info@sollex.se.

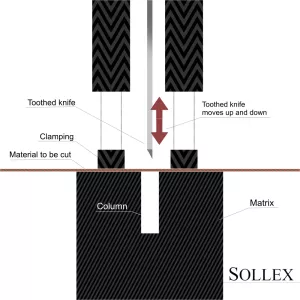

Toothed or serrated knives are defined by the fact that they have special sharpened teeth on the cutting part of the knife, which allow you to cut materials with the a low cutting force and a 90 degree cutting angle.

Toothed or serrated knives are defined by the fact that they have special sharpened teeth on the cutting part of the knife, which allow you to cut materials with the a low cutting force and a 90 degree cutting angle.

Nowadays, toothed knives with different shapes and pitches of teeth are used. Toothed blades can have a straight or circular design. Serrated blades have different lengths of teeth and different widths between them.

This category of machine knives has different names that you may come across: Toothed knives, Serrated knives, Serrated Machine knives, Tooth form blades, Straight Toothed knife blade, Circular Serrated knives, Knives with toothed edge, Scalloped knife, Toothed Cutter.

In addition, there are knives whose names are determined by the material they cut or the area of application: Tape packer blade, Tape cutter, Packaging machine knives,Toothed packaging knives, Bagging machine knives, Wrapping machine knives, and Packaging knives

Perforating blades or Perforation knives are versions of the "crush knife" that has a perforated edge. This results in a perforated cut. Depending on how many teeth the perforating knife has, you can design the perforation of the finished material.

There are two methods of cutting with perforating knives: roller cutting and vertical cutting. Roller cutting is performed with circular perforating knives by rolling over a counter knife or counter shaft, which allows continuous cutting of the web of material. Vertical cutting is performed with flat perforating knives and flat counter blades and resembles the chopping process. When cutting/perforating, perforating knives must be pressed with a certain force against the counter blade/shaft, so often when cutting (perforating) web materials, perforating knife heating technology is used to reduce the pressure applied and increase the life of the knives. A perforating knife for cross-cutting cuts small holes in the material. These holes together form a perforation.

Perforating knives are widely used in many pre-separation operations that require perforation lines and are used for cutting paper, cardboard, films, foil and other materials. The use of perforating knives is quite common in paper processing, packaging, food, printing and other equipment. An everyday use for perforated cuts is small plastic bags that are put together on a roll. To remove one of them, you simply tear open the perforation made by the knife.

Toothed knives are used in all types of filling, cutting, sealing, packing machines. They are used to evenly divide the packaging material into products one at a time, which cannot be achieved with straight edge packaging knives. They are most often used in combination with heating sponges for sealing finished products.

Sollex supplies toothed knives for many different applications:

Machine knives with toothed edge are widely used in the following manufacturing industries:

Serrated blades are used for cutting and processing the following materials:

Plastics | Bio-Plastics | Poly-tube-bags | Soft and flexible materials |

Non-woven | Film & Foil | Labels | Tape |

Textile | Packaging | Bags | Rubber |

Composite packaging | Aluminium | Cardboard / carton | Paper |

The leading manufacturers of various packaging equipment that use toothed form industrial knives in their machines and production lines: 3M, Aetna, Belcor, Bemis, Bosch, Bossar, Cermex, CFS, Colimatic, Condi film, Cryovac, Decca, Durable, Ez-Tek, Fuji, Hayssen, Hajek, Ilapak, Intertape, Kister, Love Shaw, M&H, Martini, Matrix, Marq, Mantaray, MGL, Mondini, Multivac, Omori, Pavan, PFM, Prasmatic, S&R, Reepack, Rowema, Sandiacre, Sapal, Sealpac, Siat, Sig, SMI, Supervac, Tapele, Technimodern, Tiromat, Tiropac, Tetra Pac, Ulma, Volpack, Wolf etc.

The main difference between toothed knives and other types of knives is that they, in most cases, do not require bottom knives. Cutting resembles chopping in the case of straight toothed knives and sawing in the case of circular toothed knives. The essence of cutting with toothed knives is that the material is stretched in the cutting area and the toothed knife strikes it with a certain acceleration, cutting it into two parts.

Toothed knives are commonly used to separate film, fabric, and polymer products. Such tools are widespread in packaging equipment. Perforation knives are used by industrial manufacturers for perforating materials and materials with many entry points. Industrial circular serrated knives are used to cut hard materials such as wood. Serrated machine knives have specific tooth designs that are optimized for each material to be cut.

The disadvantage of toothed machine knives is that they fray and when the blade becomes dull, resharpening them is very difficult and labor intensive. This work is mainly done by hand and is relatively time consuming as sharpening has to be done between each tooth.

In addition, cuts with serrated blades are less clean compared to cuts with a straight knife. A successful tooth form knife is a combination of the right angle of the tip and the distance between the teeth.

Sollex can manufacture both circular and straight toothed knives for a variety of applications. For regular customers our company can keep toothed knives of certain sizes in stock.

Tooth form industrial blades for different equipment have numerous design differences, so each machine blade ordered is evaluated and agreed upon individually based on the peculiarities of its design. Sollex supply toothed and perforated machine knives based on customer’s drawing, sketch or photo. If interested, contact us at order@sollex.se.

Standard knives that are in stock will be shipped the same day if an order is placed before 1 pm on weekdays. Within Sweden, delivery takes one to two business days with Schenker. Two to five working days inside Europe with UPS. Our goal is always to deliver to your address as quickly as possible.

You will be given a delivery time, which typically ranges from 4 to 9 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

All first orders from new customers are prepaid. Further orders can be paid by invoice with 30 days payment term.

Once your order is confirmed and shipped, you will receive a tracking number, which you can track.

Sollex primarily sells machine knives of standard size and form that comply with the EOM. Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

We do, however, create bespoke knives of non-standard size and shape when a drawing or explicit request is provided. For example, we can manufacture solid tungsten carbide machine knives in a variety of non-standard forms with ultra-precise and extreme tolerances, which is very useful in the MedTech industry.

When contacting a knife manufacturer to order knives for machines and slitters, providing accurate inquiries and detailed information is critical to ensure you receive industrial knives that meet the needs of your slitting, converting operations and the material you will be cutting.

If you are ordering custom machine knives from Sollex, make sure you know the exact knife dimensions, material and mounting specifications. A drawing and a worn sample for analysis are useful. If not available a photo with clear dimensions can work. Identify in your request the current cutting problems you are currently experiencing with the cutting knife you are seeking to replace. If in doubt, our experts can help you find the right knife based on your machine model and cutting needs.

To help you pick the best blade, Sollex may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

Actually, our clients and industry partners often place recurrent orders for industrial knives with predetermined delivery dates. We ensure your production process runs well by manufacturing and delivering machine knives and blades on schedule. The most important thing is to tell us the volume of required knives and deadlines and we will prepare a warehouse supply guarantee.

Sollex sales may technical assistance and guidance on choosing a slitting knife in addition to assessing and creating the best cutting solution for your application. You can consult via phone, mail, or video conference. To do this, send an email to order@sollex.se.

Read our policy on returns and claims on the “Complaint & Return” page.

There are a number of ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. Read about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance here.

JavaScript seem to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.