On-Time Order Shipments & Delivery

2025 - WEEK 15; 97%

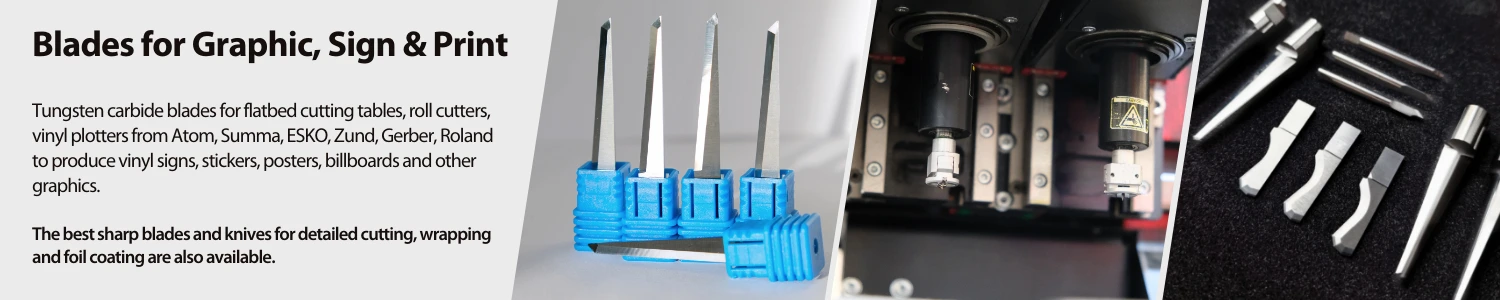

Sollex is the leader in manufacturing blades for industrial use. Sollex knives and blades are chosen by manufacturers of graphic products, signage, labels, and packaging material for their superior quality and durability. We offer blades for Summa, Gerber, Aristo, Atom, and Zund plotters. We also manufacture blades for industrial machines to order.

Worldwide shipping. Orders for in-stock items placed before 1pm will normally be dispatched the same day. For more details, please see the "Terms of Purchase and Delivery" page or contact us at order@sollex.se.

Vinyl cutter plotter is also known as vinyl cutter, vinyl plotter, cutting plotter, craft cutter. This category of cutting plotters can also include cutters and drafting equipment, including flatbed cutters, roll cutters and hard sheet cutters from brands such as Summa, Gerber and Roland.

A cutting plotter is usually controlled by a computer that can digitally produce art pieces, vinyl signs, graphics, stickers, designs, posters, billboards, T-shirt logos. The vinyl graphics are used often for outdoor advertising and marketing campaigns. Vinyl plotters are most often used to produce stickers and labels from adhesive vinyl, but they can also cut other thin materials.

You should be aware that vinyl cutters are designed by default to cut vinyl, which means that the default settings and knives included with the plotter may not be suitable for cutting graphic designs such as paper. If you are cutting other materials than vinyl, you will need to change the blade and adjust the pressure and depth of the installed blade for a good result.

The plotters have rollers that hold the cutting material and move it back and forth, and on top there is a head with a knife that rides right and left and cuts according to the design loaded in its program. The knife in the head can rotate, so it is very flexible in cutting. The tip of the plotter blade is barely visible from the head, because the material, e.g. vinyl is thin and you only need to cut the top layer and only barely touch the adhesive layer underneath the vinyl. The tip of the blade extends out of the plotter head to a distance smaller than the thickness of the bank card.

What is the difference between a vinyl cutter and a vinyl plotter, even though they are used synonymously? You could say that all vinyl cutters are plotters, not all plotters are cutters.

Vinyl cutters and vinyl plotters are used for different purposes because they have different tools. Since printing a banner on a single vinyl sheet is less costly and time intensive than creating an overlay image, many sign companies use vinyl plotters, which print large-format advertising banners with ease. For jobs that require single-color or semi-transparent vinyl, such as window tinting or vinyl coverings for cabinets, vinyl cutters are used.

To produce a multi-color design by vinyl cutter, several different cutouts of different colors of vinyl are superimposed in a pattern on top of each other. The result is a colorful image with more depth than what is printed on a single sheet of vinyl.

Because the vinyl cutter cuts rather than prints, the vinyl paper is either printed before going through the vinyl cutter or retains its original pattern before being printed.

The main device difference between a vinyl cutter and a vinyl plotter is the use of a knife, not a pen, as in conventional plotters. This blade sits on bearings that can move just like the pen and can cut out complex patterns, including lettering and other calligraphy, depending on the quality of the particular vinyl cutter.

Digital cutter is also known as cutting table, digital cutter, digital cutting system/ machine, automatic cutting machine, sign & graphic digital cutter. The digital cutter is often an industrial application and looks like a large flat vacuum table above which there are heads with knives or a pen mounted in them to process the material.

Digital Cutter is used to cut materials that cannot be cut with a vinyl cutter or a laser cutter: non-rigid and porous materials such as plastics, synthetic fabrics, foam rubber, or leather, flammable materials such as foam board and cardboard which may be too difficult or impossible to cut with roll plotters. Static cutters can also cut much thicker and heavier materials than a conventional roll or sheet plotter can handle.

The material is placed on the table, and a vacuum pump is turned on and air pressure is applied to the sheet, holding the material in place. The table then works like a normal vector plotter, using various cutting tools to cut holes or slits in the material.

You can read more about digital cutters in our “Zund Digital Cutting Systems Overview” blog article, where we took a closer look at modular cutters from Zund

Scope of application | Material to cut | Outcome of use |

Packaging industry | cardboard, polypropylene, foam materials | packaging, packing form, POS displays |

Fashion industry | woven, non-woven, fleece, felt materials, leather, textiles | textiles and leather goods, upholstery, furnishings, vehicle upholstery, carpet, accessories, clothes and shoes |

Advertising industry | sandwich board, corrugated plastic, cardboard, folding carton, films, paper, canvas, foam, foam board, PVC banner, polycarbonate, polypropylene, vinyls, rubber etc | POP-materials: shelf signage, signs, graphics, displays, labels, decals, textile banners, stickers, labels, vehicle lettering and graphics, flock/ flex templates, technical textiles |

Because digital cutting systems are often modular, it makes it possible to cut and process many different materials for different purposes that are not listed in the table above.

There is no set life span for a plotter knife, but there are some factors that it is a good idea to know and consider in your work to extend the life of your plotter knives for a longer period of time

Regularly replacing your vinyl cutter blades will keep your vinyl cutter running long and cutting smoothly and quickly. Similar rules apply to knives for use in digital cutting systems.

Similar rules apply to knives for use in digital cutting systems.

Application | Thickness of material to cut | Material to cut | |

30-degree angle plotter blades | to make shallow cuts for detail work | up to 2 millimeters thick | To cut thin media such as window tinting, film, and rice paper |

45-degree angle plotter blades | standard and universal blade to use | from 2 to 6 millimeters thick | To cut paper, vinyl, stickers - this blade is suitable for most media |

60-degree angle plotter blades | more effective for thicker or tougher media | 6 millimeters thick or thicker | To cut thick media such as flock, sandblast, rhinestone, foil, magnetic foil, masking film, reflective foil, reflective vinyl film, self-adhesive foil, self-adhesive vinyl, textile, felt |

The three most commonly used vinyl plotter blade angles are 30, 45 and 60 degrees. The only difference between the blades is the angle of the tip.

30-degree angle plotter blades

A 30-degree blade is capable of making shallow cuts. It can only cut media up to 2 millimeters thick. However, the 30-degree angle plotter blades can cut films less than 2 millimeters thick. This knife is also called a detail knife because it is the one most commonly used for any details that are less than 12 millimeters high or wide.

45-degree angle plotter blades

The blade is known as a standard blade. This blade can cut film from 2 to 6 millimeters thick. Because it offers a wider range and covers more common vinyl sizes, it is also one of the most popular blade sizes because of this flexibility. The 45-degree blades are also ideal for cutting almost any detail larger than 12 millimeters.

60-degree angle plotter blades

A 60-degree blade is capable of cutting vinyl film 6 millimeters thick or thicker. This blade is needed for instance for cutting a reflective film. This is the second most common blade along with 45-degree blades to be able to cut a wide variety of signs and graphics.

Sollex has a wide selection of plotter knives in its range. We make our blades from high quality steel and guarantee long-lasting durability. If you can't find the knife you need on our website, please contact us with a detailed request by mail order@sollex.se or phone +4635-15 75 00 and we will make a plotter knife for your company.

Standard knives that are in stock will be shipped the same day if an order is placed before 1 pm on weekdays. Within Sweden, delivery takes one to two business days with Schenker. Two to five working days inside Europe with UPS. Our goal is always to deliver to your address as quickly as possible.

You will be given a delivery time, which typically ranges from 4 to 9 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

All first orders from new customers are prepaid. Further orders can be paid by invoice with 30 days payment term.

Once your order is confirmed and shipped, you will receive a tracking number, which you can track.

Sollex primarily sells machine knives of standard size and form that comply with the EOM. Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

We do, however, create bespoke knives of non-standard size and shape when a drawing or explicit request is provided. For example, we can manufacture solid tungsten carbide machine knives in a variety of non-standard forms with ultra-precise and extreme tolerances, which is very useful in the MedTech industry.

When contacting a knife manufacturer to order knives for machines and slitters, providing accurate inquiries and detailed information is critical to ensure you receive industrial knives that meet the needs of your slitting, converting operations and the material you will be cutting.

If you are ordering custom machine knives from Sollex, make sure you know the exact knife dimensions, material and mounting specifications. A drawing and a worn sample for analysis are useful. If not available a photo with clear dimensions can work. Identify in your request the current cutting problems you are currently experiencing with the cutting knife you are seeking to replace. If in doubt, our experts can help you find the right knife based on your machine model and cutting needs.

To help you pick the best blade, Sollex may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

Actually, our clients and industry partners often place recurrent orders for industrial knives with predetermined delivery dates. We ensure your production process runs well by manufacturing and delivering machine knives and blades on schedule. The most important thing is to tell us the volume of required knives and deadlines and we will prepare a warehouse supply guarantee.

Sollex sales may technical assistance and guidance on choosing a slitting knife in addition to assessing and creating the best cutting solution for your application. You can consult via phone, mail, or video conference. To do this, send an email to order@sollex.se.

Read our policy on returns and claims on the “Complaint & Return” page.

There are a number of ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. Read about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance here.

JavaScript seem to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.