On-Time Order Shipments & Delivery

2025 - WEEK 15; 97%

With Sollex's high-quality solid tungsten carbide knives made for Zund, Summa, iEcho, ESKO, Roland, Atom, Aristo, Jwei and Gerber CNC cutting systems, you can advance your digital cutting processes. Our carefully and precisely crafted knives are designed to work and produce outstanding results with each cut. In addition, Sollex manufactures high-performance blades to customer specifications; we may be able to design blades for your cutting machine. Please contact us.

Worldwide shipping. Orders for in-stock items placed before 1pm will normally be dispatched the same day. For more details, please see the "Terms of Purchase and Delivery" page or contact us at order@sollex.se.

Plotter knives, also known as cutter or CNC knife blades, are crucial parts of digital cutting equipment. These specialist blades are essential for converting raw materials into complex patterns, designs, and products that serve a wide range of industries. They are made specifically for CNC digital cutting systems.

Plotter knives, also known as cutter or CNC knife blades, are crucial parts of digital cutting equipment. These specialist blades are essential for converting raw materials into complex patterns, designs, and products that serve a wide range of industries. They are made specifically for CNC digital cutting systems.

A high-quality cutting blade will not only improve the final product but also make the working experience more pleasurable. For a number of years, Sollex has been manufacturing cutting system blades. Our blades, which are made of tungsten carbide, are guaranteed to last a long time and remain sharp and work consistently. From sturdy foam boards and rubber to delicate films and textiles, our blades can handle a wide variety of materials.

The digital cutting knives have different designs depending on the CNC cutter type and its application. In addition to the design, the knives differ in such characteristics as:

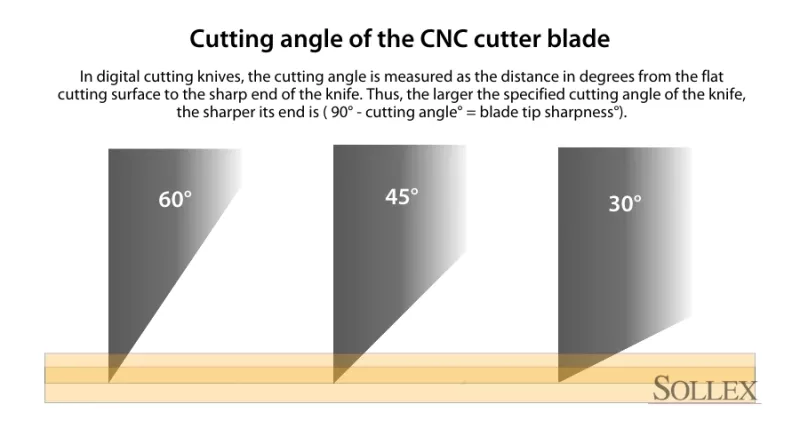

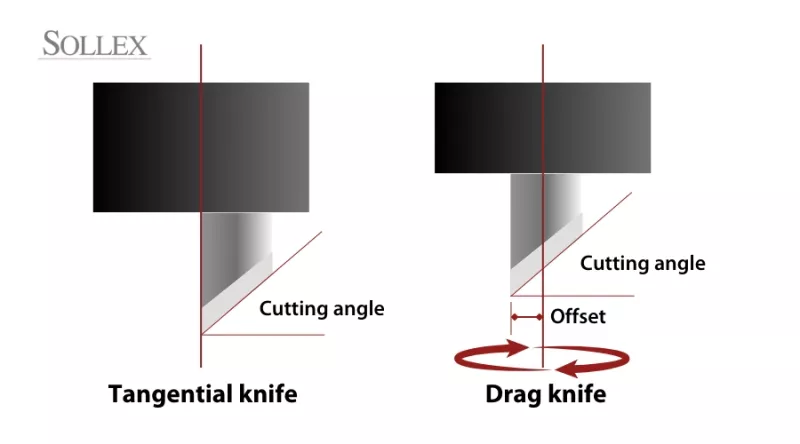

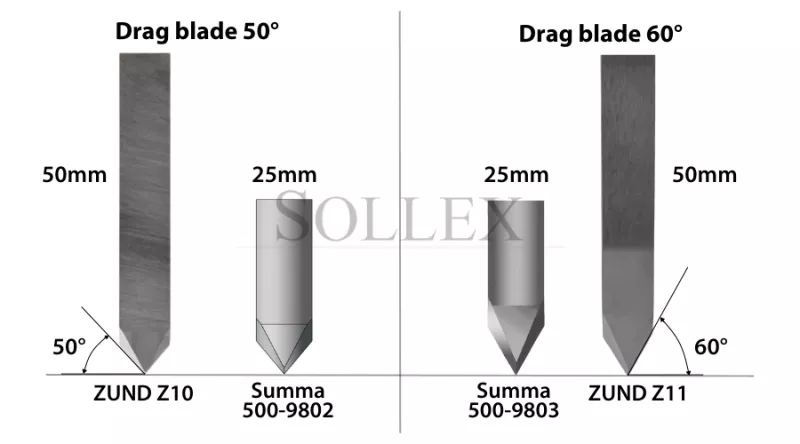

Plotter knives used in plotter and vinyl cutters have two main characteristics for a particular choice - the offset (the length from the end of the knife to its axis) and the cutting edge angle external angle, namely the angle from the cutting side of the knife to the surface of the material being cut). Plotter knives are available with cutting edge angles of 30°, 45°, and 60°. The 30° plotter knives are designed for thin films with density of 25-50 microns (standard vinyl, metallized, reflective, tinting, etc.) and cutting small parts. Knives with an angle of 45° are considered universal and are used for cutting materials of medium thickness - dense films 50-1000 microns. 60° knives are designed for cutting materials thicker than 100 microns (sandblasting, fluorescent, reflective films, etc.).

Offset is a quantity that defines the radius of rotation of the blade and compensates for distance when cornering. Correct blade offset for the drag type blade is essential for good quality corners.

Because the Zund cutting systems are modular, it makes it possible to cut and process many different materials. A list of just a few of the materials suitable for use on the Zund is as follows:

Aramid fiber | Leather | Sandwich board | Corrugated Plastic |

Cardboard/ Corrugated cardboard / Folding carton | Fabrics/ Polyester fabric / Non woven fabrics | Films | Felt |

Tarpaulin | Paper | Glass fiber | Canvas |

Foam Board/ Foam / Hardfoam | Plywood | PVC banner / PVC | Polycarbonate / Polypropylene |

Vinyls / Reflective vinyls / Self-adhesive vynils | Styrene | Soft Metals | Rubber |

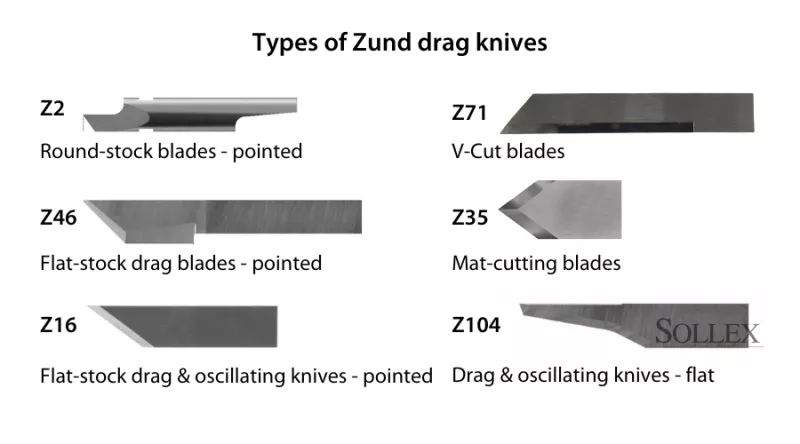

In general, there are the following types of blades for Cutters: drag blades, oscillating blades, rotary blades.

Types of plotter blades and their applications:

Drag knives move and cut through the material like a knife cuts through butter. Since the cutting motion with the drag knife technology is dragging, these knives are usually used to cut thin materials (adhesive vinyl), flexible materials (corrugated cardboard) or thicker materials but soft materials (foam board). But more typically the drag knife is used to cut self-adhesive vinyl for manufacturing stickers, stencils and labels. Cutting thicker or rigid media with drag knives may result in slight distortions or rounded corners on the material.

Round-stock drag blades | |

Flat-stock drag blades | |

V-cut drag blades | |

Mat-cutting drag blades | Z30, Z33, Z34, Z35 |

Oscillating blades – pointed | Z16, Z17, Z20, Z21, Z22, Z60, Z66, Z601, Z604, Z23, Z28, Z29, Z604, Z606, Z608 |

Oscillating blades – flat | Z26, Z41, Z42, Z61, Z62, Z63, Z64, Z68, Z69, Z82, Z201, Z202, Z203, Z204, Z603, Z605, Z607 |

Rotary blades | |

Router bits |

Sustainability is one of the key benefits with blades from Sollex. We want you to be able to feel the high quality standard throughout the whole working process. In close dialogue with the experts who uses our products, we strive to develop our products to always serve and exceed the expectations of the market. Our blades are characterized by the stable feeling that you will experience when working with your machine. We can promise you that you will feel the difference.

The tangential knife is driven by a motor, unlike the drag knife. This technology sets the knife at the desired angle with respect to the cutting surface and the direction of the future cutting path. Tangential knife technology allows perfectly shaped cut corners in the thin media, but also in thick, rigid media since there are no drag forces that will influence the knife’s trajectory.

Download PDF | Knives for Summa Cutter Table

| Summa Artnr | Name | Sollex Artnr | Sollex Name |

| TANGENTIAL Knives | |||

| 390-534 | Summa 36° Tangential Blade | T36 | Knife like T36 for Summa cutters – 36° 2pcs |

| 390-560 | Summa 45° Dual Wedge Tangential Blade | T45 | Knife like T45 for Summa cutters – 45° 5pcs |

| 390-550 | Summa 60° Tangential Blade | T60 | Knife like T60 for Summa cutters – 60° 5pcs |

| Electric Oscillating Tool Knives | |||

| 500-9801 | Summa 50° Double Edge Cutout Blade | 500-9801 | Knife like Summa 500-9801 65° 5pcs |

| 500-9802 | Summa 50° Double Edge Cutout Blade | 500-9802 | Knife like Summa 500-9802 50° 5pc |

| 500-9803 | Summa 60° Double Edge Cutout Blade | 500-9803 | Knife type Summa 500-9803 60° 5 pcs |

| 500-9807 | Summa Heavy Duty Cutout Blade | Z46 | Knife like Zund Z46 (4800073) 5pcs |

| 500-9810 | Summa Knife OT 60°-85° L25 | Z22 | Knife like Zund Z22 (3910315) 5pcs |

| 500-9811 | Summa Knife OT 65° -85° L25 | Z20 | Knife like Zund Z20 (3910313) 5pcs |

| 500-9812 | Summa Knife OT 65° -85° L28 | Z21 | Knife like Zund Z21 (3910314) 5pcs |

| 500-9814 | Summa Knife OT 45° -86° L38 | Z28 | Knife like Zund Z28 (3910318) 5pcs |

| 500-9815 | Summa Knife OT 45° -85° L33 | Z23 | Knife like Zund Z23 (5005560) 5pcs |

| Pneumatic Oscillating Knives | |||

| 500-9830 | POT Knife Flat Point L20 T0.63 | 7598 | Knife like Aristo 07265 Ø 6mm 10pcs |

| V-CUT Tool Knives | |||

| 500-9825 | V-Cut Blade, 0.90mm | 61329 | Knife V-Cut like Zund Z73 (5005572) 10pcs |

| 500-9826 | V-Cut Blade, Hard Metal | Z71 | Knife V-Cut like Zund Z71 (5006045) 5pcs |

| Rotary Knives | |||

| 500-9860 | Summa Decagonal Knife, D25 | Z50 | Rotary knife like Zund Z50 Ø25mm (3910335) 5pcs |

| 500-9862 | Summa Decagonal Knife, D32 | Z52 | Rotary knife like Zund Z52 Ø32mm (3910337) 5pcs |

At Sollex, we understand the intricacies of digital cutting and the importance of having a reliable plotter knife. Choose from drag blades, oscillating blades, rotary blades, and more to suit your specific cutting needs.

At Sollex, we understand the intricacies of digital cutting and the importance of having a reliable plotter knife. Choose from drag blades, oscillating blades, rotary blades, and more to suit your specific cutting needs.

Purchase knives from Sollex for these cutting tools:

If you are looking for a supplier of cutting consumables and knives for vinyl plotters and digital cutting tables from manufacturers such as Aristo, Atom, Esko, Kongsberg, Summa, Zund, Jingwei JWEI, Elitron, iEcho, and Gerber, Mimaki, Sollex can provide you with high quality knives on time and at an exceptional price. We manufacture plotter and cutter knives from high quality tungsten carbide and with high wear resistance.

Here you can find our drag knives, oscillating knives, tangential cutter knives, and vinyl cutter knives.

Our commitment to quality and precision has made us a trusted supplier of plotter knives for renowned cutting systems such as Zund, Summa, Aristo, Esko, Atom, Roland and Gerber. Those are high-quality machines with a reputation that goes way back. We proudly serve customers across Europe, the USA, the Middle East, and Asia, emphasizing timely and efficient delivery. Our goal is to maintain the same high quality, ensuring that our blades complement these exceptional machines perfectly.

Standard knives that are in stock will be shipped the same day if an order is placed before 1 pm on weekdays. Within Sweden, delivery takes one to two business days with Schenker. Two to five working days inside Europe with UPS. Our goal is always to deliver to your address as quickly as possible.

You will be given a delivery time, which typically ranges from 4 to 9 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

All first orders from new customers are prepaid. Further orders can be paid by invoice with 30 days payment term.

Once your order is confirmed and shipped, you will receive a tracking number, which you can track.

Sollex primarily sells machine knives of standard size and form that comply with the EOM. Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

We do, however, create bespoke knives of non-standard size and shape when a drawing or explicit request is provided. For example, we can manufacture solid tungsten carbide machine knives in a variety of non-standard forms with ultra-precise and extreme tolerances, which is very useful in the MedTech industry.

When contacting a knife manufacturer to order knives for machines and slitters, providing accurate inquiries and detailed information is critical to ensure you receive industrial knives that meet the needs of your slitting, converting operations and the material you will be cutting.

If you are ordering custom machine knives from Sollex, make sure you know the exact knife dimensions, material and mounting specifications. A drawing and a worn sample for analysis are useful. If not available a photo with clear dimensions can work. Identify in your request the current cutting problems you are currently experiencing with the cutting knife you are seeking to replace. If in doubt, our experts can help you find the right knife based on your machine model and cutting needs.

To help you pick the best blade, Sollex may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

Actually, our clients and industry partners often place recurrent orders for industrial knives with predetermined delivery dates. We ensure your production process runs well by manufacturing and delivering machine knives and blades on schedule. The most important thing is to tell us the volume of required knives and deadlines and we will prepare a warehouse supply guarantee.

Sollex sales may technical assistance and guidance on choosing a slitting knife in addition to assessing and creating the best cutting solution for your application. You can consult via phone, mail, or video conference. To do this, send an email to order@sollex.se.

Read our policy on returns and claims on the “Complaint & Return” page.

There are a number of ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. Read about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance here.

JavaScript seem to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.