On-Time Order Shipments & Delivery

2025 - WEEK 15; 97%

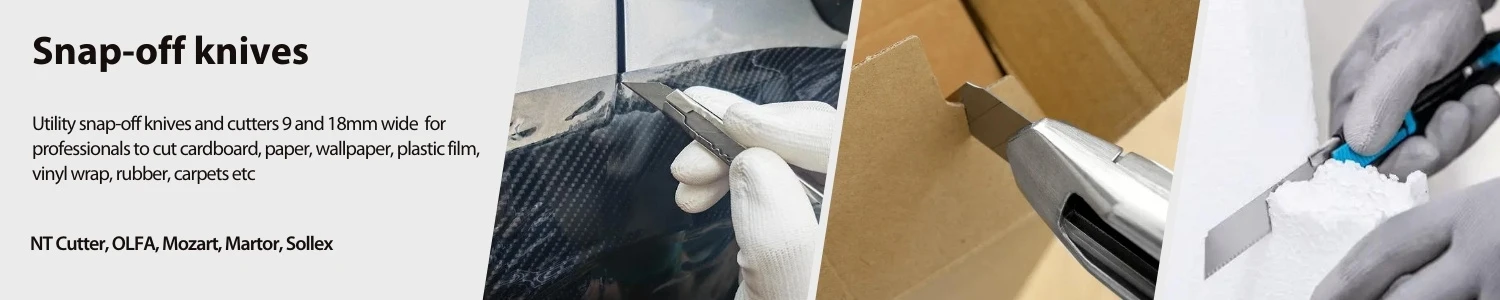

Sollex has a wide range of snap-off knives for both professional use and hobby projects. Amongst other things, there are robust knives in aluminum, fine knives for detail work, and lightweight knives in plastic. Our snap-off knives are well suited for cutting materials such as cardboard, wallpaper, plastic, paper, carpets and rubber, and are available in both large and small versions. Sollex also provides a large variation of snap-off blades, that keep high quality and sharpness.

Worldwide shipping. Orders for in-stock items placed before 1pm will normally be dispatched the same day. For more details, please see the "Terms of Purchase and Delivery" page. If you can't find what you're looking for you're very welcome to get in touch with us at +46 35-157500 or info@sollex.se.

Welcome to the Swedish knife and blade specialist Sollex! We are experts in knife blades and have cutting tools for professionals that suit many applications. Our range is a mix of the highest quality safety knives available and knives for digital cutting systems, machines and industry.

Welcome to the Swedish knife and blade specialist Sollex! We are experts in knife blades and have cutting tools for professionals that suit many applications. Our range is a mix of the highest quality safety knives available and knives for digital cutting systems, machines and industry.

With our 18mm and 9mm utility knives, you can give yourself and your employees sharpness and performance that lasts. Invest in quality and your work will be more efficient. We have knives in a variety of shapes and handles for 18mm and 9mm blade widths. By combining different types of blades, you can easily use your tool for a whole range of purposes. Please check out our product category “Snap-off blades” to see examples of different types of blades for different tasks. Sollex utility knives are of the highest quality and designed for professionals and craftsmen! We market a range of break off knives that meet the requirements and needs of professional users.

A snap-off knife is a knife with an interchangeable blade that can be broken into different segments. The blade can be pushed back and forth and locked in the desired position. The cutting blade usually consists of 8 or 9 segments. Use only one segment at a time and break it off when it becomes worn. Use pliers or a SAFETY BOX to break off the blade segments. The blade is broken off in a punched-in segment and an unused portion of the blade is brought forward and used. Then you, the user, have a very sharp knife blade quickly at hand. There are two standard widths of knife blades: 9mm and 18mm.

Do you like the idea of using more than 10 mm at a time of your utility knife? Then use blades without segments. These cannot be broken off and are well suited to use up to 70 mm out from the knife. Blades without segments are supplied as standard in the Martor 380001 safety knife. You can order knife blades without segments from Sollex and these are called Sollex 180LUS.

Snap-off knives are used together with segmented snap-off blades. When the knife needs to change blades, it is easy to open the hilt and insert a new blade. When the blade becomes blunt, a new edge is simply snapped off, so you always have a sharp working tool. We recommend using Sollex knife blades, which will make any knife really sharp and durable. Sollex blades are made of special German ice-hardened steel and cut through most materials without resistance.

Sollex knife blades and knives can be used to cut through thick plastic, rubber, foil, cardboard, paper, textiles, wallpaper, flooring materials and leather, for example.

One Sollex customer employed 67 people in their warehouse. Approximately 30 Stanley snap off knives were used per week to open and cut cartons. The cost was about SEK 30 per disposable knife. The total cost over a four-year period was estimated at SEK 180 000. The Sollex 5180 utility knife was labeled with each employee's name. The cost of the knives and professional blades was SEK 3,772. The knives are still working today and have reduced the need for disposable knives and improved health and safety. The savings to the customer from using the correct blade was SEK 176,000 over four years.

When you unpack the utility knives and blades you order, we want you to feel the same love for the product as we do when we make them. All of our utility blades are made to a high quality and are designed for professional users. By choosing high quality tools, you get cutting performance that won't fade over time. We also offer fast delivery because we know how important it is to have sharp blades for your pruning knife!

Utility snap-off knives are used for various tasks in construction and manufacturing operations. Whether you're looking for a sturdy utility knife for demanding cutting jobs or a more nimble version, Sollex has the knife for you. If you have any questions about our snap-off knives, how to buy or anything else - get in touch with our customer service and we will be happy to help you with your questions! Buy your blades and blades online!

Standard knives that are in stock will be shipped the same day if an order is placed before 1 pm on weekdays. Within Sweden, delivery takes one to two business days with Schenker. Two to five working days inside Europe with UPS. Our goal is always to deliver to your address as quickly as possible.

You will be given a delivery time, which typically ranges from 4 to 9 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

All first orders from new customers are prepaid. Further orders can be paid by invoice with 30 days payment term.

Once your order is confirmed and shipped, you will receive a tracking number, which you can track.

Sollex primarily sells machine knives of standard size and form that comply with the EOM. Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

We do, however, create bespoke knives of non-standard size and shape when a drawing or explicit request is provided. For example, we can manufacture solid tungsten carbide machine knives in a variety of non-standard forms with ultra-precise and extreme tolerances, which is very useful in the MedTech industry.

When contacting a knife manufacturer to order knives for machines and slitters, providing accurate inquiries and detailed information is critical to ensure you receive industrial knives that meet the needs of your slitting, converting operations and the material you will be cutting.

If you are ordering custom machine knives from Sollex, make sure you know the exact knife dimensions, material and mounting specifications. A drawing and a worn sample for analysis are useful. If not available a photo with clear dimensions can work. Identify in your request the current cutting problems you are currently experiencing with the cutting knife you are seeking to replace. If in doubt, our experts can help you find the right knife based on your machine model and cutting needs.

To help you pick the best blade, Sollex may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

Actually, our clients and industry partners often place recurrent orders for industrial knives with predetermined delivery dates. We ensure your production process runs well by manufacturing and delivering machine knives and blades on schedule. The most important thing is to tell us the volume of required knives and deadlines and we will prepare a warehouse supply guarantee.

Sollex sales may technical assistance and guidance on choosing a slitting knife in addition to assessing and creating the best cutting solution for your application. You can consult via phone, mail, or video conference. To do this, send an email to order@sollex.se.

Read our policy on returns and claims on the “Complaint & Return” page.

There are a number of ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. Read about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance here.

JavaScript seem to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.