On-Time Order Shipments & Delivery

2025 - WEEK 15; 97%

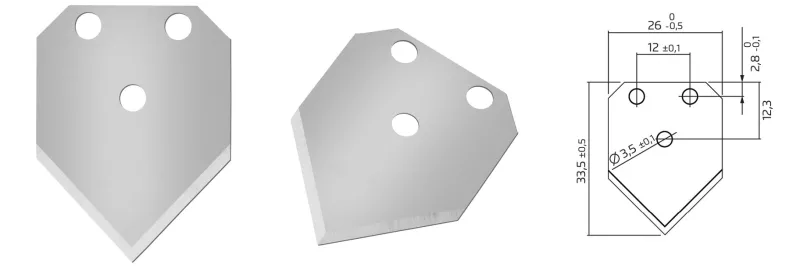

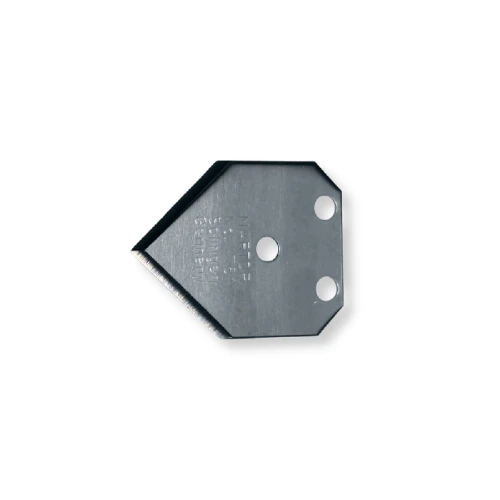

Do you need high quality pointed tip machine blades? Sollex manufactures and supplies point blades according to your needs, which means that you as a customer can get exactly the triangular blades you need. All our pointed triangular blades are made from high quality steel, so you can be confident that these machine knives will perform well over time.

Do you need high quality pointed tip machine blades? Sollex manufactures and supplies point blades according to your needs, which means that you as a customer can get exactly the triangular blades you need. All our pointed triangular blades are made from high quality steel, so you can be confident that these machine knives will perform well over time.

Worldwide shipping. Orders for in-stock items placed before 1pm will normally be dispatched the same day. For more details, please see the "Terms of Purchase and Delivery" page or contact us at order@sollex.se.

We have been manufacturing machine knives and blades for many years and have been named one of the best manufacturers on the market. The Swedish industry has a good reputation and we are very proud to be part of spreading Sollex quality products to our customers. Don't hesitate, get in touch with us on +4635 - 15 75 00.

Due to their sharp point design, machine knives with a pointed tip are perfect for piercing and cutting harder materials like paper, rubber, cardboard, and plastics. Industrial blades are used to improve the shape, perforation, and cut intricate shapes, as well as enhance the properties and design of final products. They are designed to have a sharpened cutting tip that requires less penetration force when entering a material vertically.

Due to their sharp point design, machine knives with a pointed tip are perfect for piercing and cutting harder materials like paper, rubber, cardboard, and plastics. Industrial blades are used to improve the shape, perforation, and cut intricate shapes, as well as enhance the properties and design of final products. They are designed to have a sharpened cutting tip that requires less penetration force when entering a material vertically.

Industrial pointed knives are made of carbon steel, solid tungsten carbide or tooling steel. The material choice makes them durable for repeated industrial use and resistant to wear and tear while maintaining sharpness. Blade edges can be coated to improve and prolong the cutting performance.

Industrial pointed-tip knives are very sharp allowing them to work vertically well on paper, non woven, polymers, composites and rubber and other materials.

Sollex pointed blades have many different uses. In general, pointed blades are used for two things: cutting and making holes in various materials such as tubing, cardboard and styrofoam.

The high quality steel in the pointed blades makes them especially suitable for challenging work. If you need to cut materials such as hose or cardboard, we have different models to choose from. Some blades are coated with a ceramic coating, which considerably extends the durability and performance of the blade. The coating on the blade’s edge acts as a protection, prolongs durability, and changes the surface smoothness. We also manufacture pointed tip blades in solid tungsten carbide for extreme durability.

Pointed tip knives, characterized by their sharp, tapered ends, are essential tools in various industrial applications. The versatility of pointed tip industrial knives makes them valuable tools in various sectors.

Material | Description |

|---|---|

Plastics and Polymers | These knives are used for cutting and shaping various types of plastics, including PVC, PET, and other thermoplastics, often used in packaging and manufacturing industries. |

Rubber | In the rubber industry, pointed tip knives are essential for cutting sheets, strips, and custom shapes with precision. |

Textiles and Fabrics | These knives can be used for cutting textiles with precision, especially in applications where the edges need to be clean and fray-free. |

Paper and Cardboard | Pointed tip knives are ideal for cutting paper and cardboard, especially in packaging and printing industries, where precise cuts and shapes are required. |

Foam and Sponge Materials | For industrial applications involving foam and sponge materials, these knives provide the precision needed for custom shapes and sizes. |

Composite Materials | Used in aerospace, automotive, and other industries, pointed tip knives are suitable for cutting composite materials like fiberglass and carbon fiber composites. |

In the plastic film industry, pointed blades are often used to perforate or cut various types of plastic films without tearing. This type of cut precision is critical to maintaining film integrity, especially when the film is used for packaging or as a component of large products.

One Sollex customer is a major UK player within Blown Film Extrusion, Flexographic Printing, Complex Laminates, and Bag Production. They create technically advanced PE films and use Sollex pointed blades for making perforations in their final products. They use a special version of the 760.50 pointed blade.

The rubber industry benefits greatly from the sharpness and precision of pointed tip blades. When cutting and piercing tubes, shaping parts or creating complex structures, these blades provide the precision required to produce high-quality rubber products. Sharp-tipped blades are especially used for making perforations, holes or shaping rubber products.

Read an article about how Sollex's pointy-tip knives are used to cut and puncture plastic tubing in the manufacture of control and condition monitoring systems for rock reinforcement - Method for Rock Reinforcement with Rock Bolts - Customer Case.

Hose is advantageously cut with a pointed knife. Suggestions are Sollex Pointed Blade 761V or Double edge pointed blade 824. We also manufacture pointed blades in larger sizes according to customers’ drawing.

Cardboard is best cut with a pointed knife to make different hole patterns in the cardboard. Think about how big a cut you want in the cardboard and try a knife blade with a similar edge. When the right shape of the pointed blade is found for cutting cardboard, we can coat the pointed blade for increased durability.

Cardboard is best cut with a pointed knife to make different hole patterns in the cardboard. Think about how big a cut you want in the cardboard and try a knife blade with a similar edge. When the right shape of the pointed blade is found for cutting cardboard, we can coat the pointed blade for increased durability.

One major global paper packaging manufacturer that makes protective paper-based packaging uses Sollex 761V pointed blade for making perforation in the paper packaging.

One Sollex customer is a prominent force in the textile machinery market making machines for weaving, textile finishing, and technical textiles. Their machines produce knits, woven fabrics, and technical textiles. This customer uses the blade 752V.

The sharp pointed blades provide the clean, precise cuts needed to create packaging and cardboard products. Packaging often requires intricate shapes and designs, especially for customized packaging solutions.

The industrial knives with pointed tips are customized to a variety of materials, allowing them to be used for a wide range of packaging types, from plastic and foil wraps to cartons and bubble wrap. The sharp, pointed tip is ideal for starting to cut tough or durable materials commonly used in packaging, such as thick cardboard, heavy-duty plastics or laminates.

The pointed machine knives can be custom designed to meet specific packaging requirements, whether it be a unique shape, size or material composition, providing flexibility in packaging design and production.

Styrofoam is a complex material and it is advantageous to use a pointed knife blade to make a hole pattern or cut. Sollex Pointed blade 761V or Pointed blade double edged 824 are two examples of knife blades used for cutting cellular plastic and styrofoam. We also manufacture pointed knives in larger sizes according to drawings for cutting styrofoam and cellular plastic.

Most of the pointed blades we sell are made by us. However, we also supply knives from Olfa, Mozart, Lutz and Martor. This is to cover all standard dimensions. It also gives you as a customer the opportunity to buy ready-made blades at a good price. Likewise, it can be useful to test finished blades from Olfa, Lutz, Mozart, and Martor if you want to test a pointed blade design in your cutting process.

Do you need high quality pointed tip blades? Sollex manufactures and supplies pointed tip blades. All our pointed tip blades are made from high quality steel or tungsten carbide, so you can be confident that your pointed knives will perform well over time. We have been manufacturing pointed blades for many years and have been named one of the best manufacturers on the market. The Swedish industry has a good reputation and we are very proud to be part of spreading Sollex quality products to our customers.

Do you feel unsure about which tip blade is best suited for your purposes? Give us a call and we'll help you with your choice. You can reach us on +4635 15 75 00 or order@sollex.se.

Standard knives that are in stock will be shipped the same day if an order is placed before 1 pm on weekdays. Within Sweden, delivery takes one to two business days with Schenker. Two to five working days inside Europe with UPS. Our goal is always to deliver to your address as quickly as possible.

You will be given a delivery time, which typically ranges from 4 to 9 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

All first orders from new customers are prepaid. Further orders can be paid by invoice with 30 days payment term.

Once your order is confirmed and shipped, you will receive a tracking number, which you can track.

Sollex primarily sells machine knives of standard size and form that comply with the EOM. Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

We do, however, create bespoke knives of non-standard size and shape when a drawing or explicit request is provided. For example, we can manufacture solid tungsten carbide machine knives in a variety of non-standard forms with ultra-precise and extreme tolerances, which is very useful in the MedTech industry.

When contacting a knife manufacturer to order knives for machines and slitters, providing accurate inquiries and detailed information is critical to ensure you receive industrial knives that meet the needs of your slitting, converting operations and the material you will be cutting.

If you are ordering custom machine knives from Sollex, make sure you know the exact knife dimensions, material and mounting specifications. A drawing and a worn sample for analysis are useful. If not available a photo with clear dimensions can work. Identify in your request the current cutting problems you are currently experiencing with the cutting knife you are seeking to replace. If in doubt, our experts can help you find the right knife based on your machine model and cutting needs.

To help you pick the best blade, Sollex may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

Actually, our clients and industry partners often place recurrent orders for industrial knives with predetermined delivery dates. We ensure your production process runs well by manufacturing and delivering machine knives and blades on schedule. The most important thing is to tell us the volume of required knives and deadlines and we will prepare a warehouse supply guarantee.

Sollex sales may technical assistance and guidance on choosing a slitting knife in addition to assessing and creating the best cutting solution for your application. You can consult via phone, mail, or video conference. To do this, send an email to order@sollex.se.

Read our policy on returns and claims on the “Complaint & Return” page.

There are a number of ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. Read about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance here.

JavaScript seem to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.