On-Time Order Shipments & Delivery

2025 - WEEK 15; 97%

Sollex manufactures custom circular knives to order, which means that you as a customer can get exactly the circular knife you require. All we need from you to produce your knife is a drawing or part number. All of our circular knives are made from durable tool steel or so-called quality steel, so you can be confident that your product will perform well over time.

Worldwide shipping. Orders for in-stock items placed before 1pm will normally be dispatched the same day. For more details, please see the "Terms of Purchase and Delivery" page. If you can't find what you're looking for you're very welcome to get in touch with us at +46 35-157500 or info@sollex.se.

We have been manufacturing circular knives for many years and have been named one of the best manufacturers on the market. The Swedish industry has a good reputation and we are very proud to be part of spreading more Swedish quality products to our customers. We have experience in developing circular knives for food processing, paper, packaging, plastics, printing, rubber, floor and wall, automotive etc.

| Type of circular knife | Sollex Circular Knives | Material to cut |

| Dished Circular Knives | RDD130X80, RDD130X100, RDD140X70, RDS65X40, P881A, RDS75x40x1 | circular dished knives for cutting paper, cardboard, paperboard, labels, adhesive tape, cable, litho tape, aluminum foil, non-ferrous metals, film, foil, non-woven, textile, rubber |

| Perforating Circular Knives | P829-2, P829-3 | for perforation of paper, cellophane, foils, cardboard, packaging |

| Crush Cutter Knives | P831, P834 | for crush cutting of rubber, adhesive tapes, non-woven, tissue, emery, textiles, pressure sensitive materials, coated paper |

| Circular knives | R30, R71-SHARP, R71-BLUNT, R105, R150, R28X6X4-70, R30-010, R30-010-X, R45X8, P829-1, R70X40X1, P847, P855-1, R30-010, | for slitting of various material such as plastic film, non woven, paper etc |

| Rotary Cutter Knives | OLFA RB60-1, R18-2, R28-5, R45 | for cutting paper, fabrics, textile, leather, felt, thin plastic sheet, plastic film soft materials |

| Bottom circular knives | RBF130 | for shear cutting of plastic film, plastic foil, adhesive tapes, non-woven, paper and carton |

| Serrated Circular Knives | R170, R200 | fits all kinds of use including food processing such bakery, poultry, meat processing and packaging as well as many other industrial uses |

| Custom-made Circular Knives |

Sollex adapts the design of the knife to the application and the cutting material |

| Diameter of circular knives | Sollex Knife Product Item |

| Circular knives up to 60 mm in diameter | R30, R28X6X4-70, R30-010, R30-010-X, R45X8, RB60-1, R18-2, R28-5, R45 |

| Circular knives over 60 mm in diameter | R71-SHARP, R71-BLUNT, R150, P829-1,R70x40x1, P847, P855-1, P829-3, P829-2, P834, P831, RDS75x40x1, RDD130X80, RDD130X100, RDD140X70, RDS65X40, P881A |

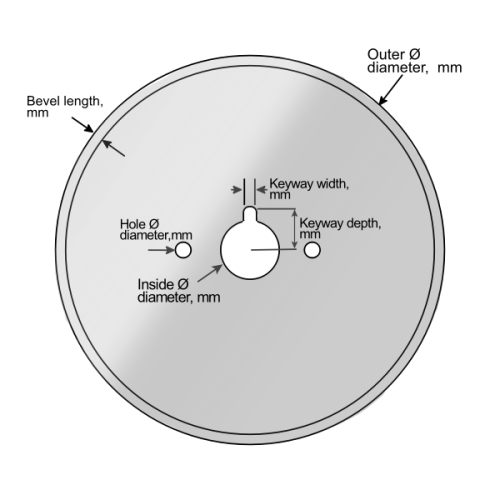

The circular knife is a popular and versatile tool for industrial application. It is mainly needed for sharpening and cutting various materials, regardless of their flexibility and hardness. Typical circular blades have a circular shape and a hole in the center, necessary for a firm grip during cutting. The thickness of the working blade is selected depending on the materials to be cut. The main characteristics of a circular knife are the outer diameter (the size of the knife from one edge to the opposite edge through the center), the inner diameter (the diameter of the central hole intended for attachment to the holder), the thickness of the knife, bevel and the angle of bevel.

The circular knife is a popular and versatile tool for industrial application. It is mainly needed for sharpening and cutting various materials, regardless of their flexibility and hardness. Typical circular blades have a circular shape and a hole in the center, necessary for a firm grip during cutting. The thickness of the working blade is selected depending on the materials to be cut. The main characteristics of a circular knife are the outer diameter (the size of the knife from one edge to the opposite edge through the center), the inner diameter (the diameter of the central hole intended for attachment to the holder), the thickness of the knife, bevel and the angle of bevel.

Areas of application of circular knives:

universal application |

paper |

cardboard |

paperboard |

labels |

adhesive tape |

cable |

litho tape |

packaging |

wood |

foam |

food processing |

aluminum foil |

non-ferrous metals |

plastic film |

foil |

non-woven |

textile |

rubber | soft materials |

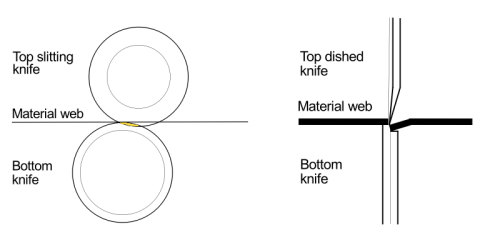

Top slitting knives are also called Dished knives as they have a shape of a dished plate. Top slitter knives are used for cutting film, paper and in the processing industry. Top and bottom knives work in pairs as the top knife regrinds when in contact with the bottom knife. Top knives are used for cutting material webs and give a really long lasting durability. Dished knives are relatively easy to regrind. The top slitter blade can be dish shaped or flat shaped with single, double bevel (edge) or square edged. For the score cutting, there is only one blade that works as the roll or sleeve stand as the bottom blade. Besides some of our customers also called top slitter blades as male or front blades.

Dished knives (or the knives can be named also rotary shear blades, top slitting knife, top dish slitter knife) can be used for a wide range of machine types. The high quality steel in the knives makes them especially suitable for challenging work. If you have to cut materials with a lot of glue and dirt, you don't have to worry about it sticking to the blade. The surface coating of the knives acts as a protection. Our knives can cut through plastic film, carpets, rubber, paper and much more.

Dished knives (or the knives can be named also rotary shear blades, top slitting knife, top dish slitter knife) can be used for a wide range of machine types. The high quality steel in the knives makes them especially suitable for challenging work. If you have to cut materials with a lot of glue and dirt, you don't have to worry about it sticking to the blade. The surface coating of the knives acts as a protection. Our knives can cut through plastic film, carpets, rubber, paper and much more.

The top slitter blade can be dish shaped or flat shaped with single, double bevel (edge) or square edged. For the score cutting, there is only one blade that works as the roll or sleeve stand as the bottom blade. Besides some of our customers also called top slitter blades as male or front blades.

The cutting edge of these tools is very diverse and depends on the type of material being cut. It can have a single-sided blade, with a ground back or double-sided blade, etc.

Fields of application: hard materials for ex cardboard, thick plastic-/ aluminum foils

Fields of application: paper, light cardboard, textiles, nonwoven, tissue

Fields of application: thin paper, thin plastic-/ aluminum foils, labels, multilayer paper

Angle of bevel |

Material to cut |

0-10° |

metals, laminates, plastics |

30° |

paper, foils, laminates, fleece, cardboard, nonwoven, tissue |

45/ 60° |

special application, film industry, multilayer paper |

Bottom knives are used in pairs with Top slitting knives / Dished knives. The bottom knife is located on the lower shaft compared to the top knife. The main principle for a bottom knife is to position the material web and stretch it for the top knife to cut it. In addition, the bottom knife should “regrind” the top knife when it comes in contact with the top knife. Therefore it is absolute imperative that the bottom knife is angled correctly. Without a correct angled bottom knife the knife pair will not perform satisfactory.

Possible characteristics that influence the choice of a circular industrial knife:

For example, the Sollex professional circular industrial knife R105 in HSS-M2 steel was developed for a plastic film company in Dubai. This knife has a double-sided sharpening to fit a shaft diameter of 34 mm. The dimensions of the circular knife are 105x34x1,5 mm, where its outer diameter (D1) is 105 mm, inner diameter (D2) is 34 mm and thickness is 1,5 mm).

Advantage of circular knives from Sollex is that performance and durability are significantly extended. Many other knives on the market work satisfactorily for a short time, when the blade is new, but quickly become worn out. As a result, they become harder and harder to work with. With circular knives from Sollex, you can work with the same precision for a much longer time.

Do you feel unsure which circular knife is best suited for your purposes? Give us a call and we'll help you with your choice. You can reach us on +4635-15 75 00 or order@sollex.se

Standard knives that are in stock will be shipped the same day if an order is placed before 1 pm on weekdays. Within Sweden, delivery takes one to two business days with Schenker. Two to five working days inside Europe with UPS. Our goal is always to deliver to your address as quickly as possible.

You will be given a delivery time, which typically ranges from 4 to 9 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

All first orders from new customers are prepaid. Further orders can be paid by invoice with 30 days payment term.

Once your order is confirmed and shipped, you will receive a tracking number, which you can track.

Sollex primarily sells machine knives of standard size and form that comply with the EOM. Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

We do, however, create bespoke knives of non-standard size and shape when a drawing or explicit request is provided. For example, we can manufacture solid tungsten carbide machine knives in a variety of non-standard forms with ultra-precise and extreme tolerances, which is very useful in the MedTech industry.

When contacting a knife manufacturer to order knives for machines and slitters, providing accurate inquiries and detailed information is critical to ensure you receive industrial knives that meet the needs of your slitting, converting operations and the material you will be cutting.

If you are ordering custom machine knives from Sollex, make sure you know the exact knife dimensions, material and mounting specifications. A drawing and a worn sample for analysis are useful. If not available a photo with clear dimensions can work. Identify in your request the current cutting problems you are currently experiencing with the cutting knife you are seeking to replace. If in doubt, our experts can help you find the right knife based on your machine model and cutting needs.

To help you pick the best blade, Sollex may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

Actually, our clients and industry partners often place recurrent orders for industrial knives with predetermined delivery dates. We ensure your production process runs well by manufacturing and delivering machine knives and blades on schedule. The most important thing is to tell us the volume of required knives and deadlines and we will prepare a warehouse supply guarantee.

Sollex sales may technical assistance and guidance on choosing a slitting knife in addition to assessing and creating the best cutting solution for your application. You can consult via phone, mail, or video conference. To do this, send an email to order@sollex.se.

Read our policy on returns and claims on the “Complaint & Return” page.

There are a number of ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. Read about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance here.

JavaScript seem to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.