On-Time Order Shipments & Delivery

2025 - WEEK 15; 97%

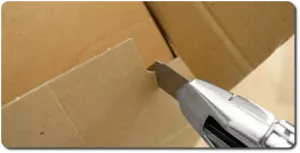

Warehouse workers often use cutting tools and techniques. They use tools such as knives, scissors, snap-off or utility knives, and cutters to open packages, separate materials, trim excess packaging, and modify products as needed. These cutting operations are essential to preparing items for storage, distribution, and shipping, ensuring they are ready for the next step in the supply chain. On this page, we have collected the knives, cutters, safety knives and scissors needed for warehousing, shipping and packaging goods.

Worldwide shipping. Orders for in-stock items placed before 1pm will normally be dispatched the same day. For more details, please see the "Terms of Purchase and Delivery" page or contact us at order@sollex.se.

We offer several choices in knives and cutting tools for warehouse and packaging use:

We offer several choices in knives and cutting tools for warehouse and packaging use:

Safety knives are the ideal cutting tool for workers in warehouses, distribution and logistics centers. In addition, in such departments the amount of cutting of different materials is unlimited. Therefore, it is hard for us to imagine that companies do not choose to use safety knives for their employees and do not purchase them for this cutting activity. Safety and the prevention of injuries are always a priority in the workplace, which is why we offer a variety of cutting tools for warehouse workers.

In addition to the safety of the worker when cutting, for example, cartons with goods, the goods are also protected. The right depth of cutting with a safety knife when opening a box can save the products in the boxes from accidental cutting and damage. In addition - a huge amount of money is also saved for the company.

Use safety knives in the following cutting operations:

Select a safety knife according to the following factors: blade retraction function, depth of cut, material to be cut, intensity and duration of use of the cutter.

Select a safety knife according to the following factors: blade retraction function, depth of cut, material to be cut, intensity and duration of use of the cutter.

For example, knives from Martor Secumax, Secupro and Secunorm series have different blade extension options: automatic, fully automatic, manual and non-retractable fixed blade.

The cutting depth of safety knives varies from 4 to 70mm.

The material that can be cut perfectly with safety knives is cardboard, plastic, tape, film and packaging film, plastic packaging bands, layers of paper and film.

The safety knives are most often suitable for both right- and left-handed users.

Read our blog about how to choose the right safety knife and how to prevent accidental cuts and lacerations in the workplace. If you need help or advice, please contact us by mail or phone.

Box cutters and tape cutters are commonly used to open cardboard, boxes and various packaged goods when receiving goods. Box cutter knives have a hidden blade head that is not exposed to the sharp edges of the blade for maximum safety when cutting hard to reach corners of boxes, packing tape and strapping. The blade shape allows easy and safe opening and cutting with a "pull" motion. The user grips the hook on the material to be cut and pulls it sideways at a 45-degree angle, downward or toward him.

Box cutters and tape cutters are commonly used to open cardboard, boxes and various packaged goods when receiving goods. Box cutter knives have a hidden blade head that is not exposed to the sharp edges of the blade for maximum safety when cutting hard to reach corners of boxes, packing tape and strapping. The blade shape allows easy and safe opening and cutting with a "pull" motion. The user grips the hook on the material to be cut and pulls it sideways at a 45-degree angle, downward or toward him.

Use box cutters for:

These knives are also safe because they have concealed blades. Box cutter knives come in two types: disposable and with a replaceable blade head. Both types of knives are available in our assortment. Choose the knives according to price and design.

Snap-off knives can be a good choice for cutting cardboard into pieces. It is important that there are no segments on the installed snap-off blade. This eliminates the risk of the blade breaking when the box is cut and prevents an accident. When cutting cardboard, do not use a regular folding snap-off or utility knife. You must also make sure that the blade is securely locked and sharp enough to cut through the thickness of the cardboard. Cut the box at a 45-degree angle.

Snap-off knives can be a good choice for cutting cardboard into pieces. It is important that there are no segments on the installed snap-off blade. This eliminates the risk of the blade breaking when the box is cut and prevents an accident. When cutting cardboard, do not use a regular folding snap-off or utility knife. You must also make sure that the blade is securely locked and sharp enough to cut through the thickness of the cardboard. Cut the box at a 45-degree angle.

Scissors are handy tools in a warehouse environment and can be used for precision cutting that requires more control than cutting tools such as utility knives. Scissors can cut through almost any material. They are also quite safe to use. However, we recommend using safety scissors, which eliminate the risk of accidental cutting. For example, with Martor scissors it is impossible to cut your finger, but they can easily cut through any packaging material.

Cutting cardboard can be tricky if you don't use the right technique. Here are some steps to help you cut cardboard in the best way possible:

These products are suitable for cutting cardboard:

Many industrial cuts occur when workers are collecting used knife blades. Perhaps they have been thrown in a waste bin and another worker repacks the waste to save space but has the unpleasant surprise of being cut. Another risk of leaving used knife blades lying around is that you can be injured by a careless movement. Even worse, children can get hurt if you leave used blades lying around.

Many industrial cuts occur when workers are collecting used knife blades. Perhaps they have been thrown in a waste bin and another worker repacks the waste to save space but has the unpleasant surprise of being cut. Another risk of leaving used knife blades lying around is that you can be injured by a careless movement. Even worse, children can get hurt if you leave used blades lying around.

Used knife blades should be separated from other waste and recycled as metal. Martor and Sollex have developed specific recycling containers that can safely store and handle your used knife blades. These are visually pleasing and safe. Martor's solution is assembled on site while Sollex is more convenient to carry in your toolbox. The important thing is to make sure you always put the used blades in the right place and recycle them correctly.

Standard knives that are in stock will be shipped the same day if an order is placed before 1 pm on weekdays. Within Sweden, delivery takes one to two business days with Schenker. Two to five working days inside Europe with UPS. Our goal is always to deliver to your address as quickly as possible.

You will be given a delivery time, which typically ranges from 4 to 9 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

All first orders from new customers are prepaid. Further orders can be paid by invoice with 30 days payment term.

Once your order is confirmed and shipped, you will receive a tracking number, which you can track.

Sollex primarily sells machine knives of standard size and form that comply with the EOM. Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

We do, however, create bespoke knives of non-standard size and shape when a drawing or explicit request is provided. For example, we can manufacture solid tungsten carbide machine knives in a variety of non-standard forms with ultra-precise and extreme tolerances, which is very useful in the MedTech industry.

When contacting a knife manufacturer to order knives for machines and slitters, providing accurate inquiries and detailed information is critical to ensure you receive industrial knives that meet the needs of your slitting, converting operations and the material you will be cutting.

If you are ordering custom machine knives from Sollex, make sure you know the exact knife dimensions, material and mounting specifications. A drawing and a worn sample for analysis are useful. If not available a photo with clear dimensions can work. Identify in your request the current cutting problems you are currently experiencing with the cutting knife you are seeking to replace. If in doubt, our experts can help you find the right knife based on your machine model and cutting needs.

To help you pick the best blade, Sollex may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

Actually, our clients and industry partners often place recurrent orders for industrial knives with predetermined delivery dates. We ensure your production process runs well by manufacturing and delivering machine knives and blades on schedule. The most important thing is to tell us the volume of required knives and deadlines and we will prepare a warehouse supply guarantee.

Sollex sales may technical assistance and guidance on choosing a slitting knife in addition to assessing and creating the best cutting solution for your application. You can consult via phone, mail, or video conference. To do this, send an email to order@sollex.se.

Read our policy on returns and claims on the “Complaint & Return” page.

There are a number of ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. Read about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance here.

JavaScript seem to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.