On-Time Order Shipments & Delivery

2025 - WEEK 15; 97%

If it’s sharp knife blades of high quality you are looking for, look no further! Here you will find blades optimized for cutting drywall, floor mats, and linoleum. Thanks to the metal composition, ice-hardening, and special grinding of our knife blades, we have achieved outstanding sharpness and durability to allow you to cut through most materials quickly and easily! No matter if it’s your first cut or hundredth.

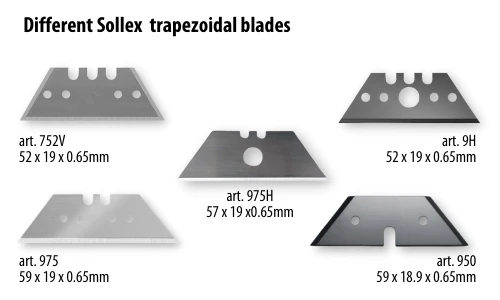

Sollex blades are 50/52mm or 59/61mm long and fit most knives on the market. But we especially recommend using the trapezoidal blades of the PRO series with the 2000 construction knife and the 1280 dolphin knife. Some of the blades are coated on the cutting edge so that they will be better suited for cutting in certain types of hard-wearing materials. You can read more about Sollex's coatings and product qualities here.

Worldwide shipping. Orders for in-stock items placed before 1pm will normally be dispatched the same day. For more details, please see the "Terms of Purchase and Delivery" page. If you can't find what you're looking for you're very welcome to get in touch with us at +46 35-157500 or info@sollex.se.

What we refer to as a utility knife blade is the most widely available all-purpose utility knife blade. The phrases "stanley blade" or "trapezoidal blade" are appropriate.

What we refer to as a utility knife blade is the most widely available all-purpose utility knife blade. The phrases "stanley blade" or "trapezoidal blade" are appropriate.

59 mm long trapezoidal utility knife blades work well for cutting gypsum board and diverse construction materials. The shorter utility knife blade, which is 52 mm long and has three mounting slots on its top side, use when you want a knife blade with a shorter, stronger tip that is better fixed.

Sollex designs and manufactures high-quality knife blades that are known for their durability and performance. The metal composition, ice-hardening, and special grinding give Sollex knife blades fantastic cutting-edge performance. Sharpness and durability mean that it feels like cutting butter with Sollex's blade even in the toughest material.

It doesn't matter if you're using the blade for the first or hundredth time. Sollex has a wide range of utility blades for cutting different materials.

There are three general users of short trapezoid blades: floor installers, safety knives, and industrial machines.

Blades with length 59-61mm have a standard thickness of 0.65 mm and approximate dimensions with small deviations of 0.1-0.2 mm: 59x19x0.65mm, 60x19x0.65mm or 61x19x0.65mm.

Blades with length 59-61mm have a standard thickness of 0.65 mm and approximate dimensions with small deviations of 0.1-0.2 mm: 59x19x0.65mm, 60x19x0.65mm or 61x19x0.65mm.

The shorter blades with length 50-52mm have a standard thickness of 0.65mm and approximate dimensions with small deviations of 0.1-0.2mm: 52x19x0.65mm or with two fixing notches 50x19x0.65mm.

The blades are 59 / 61mm long and fit most holders on the market. The coating on the edge of some of the blades enhances their ability to cut through tougher materials. The cutting edge grinding is generally single-edged, two-sided, double bevel sharpening.

Sollex offers a variety of utility blades that are suitable to cut and various materials. The universal utility blades are 59/61mm long and fit most knives on the market. Some of the blades have a coating on the edge, which makes them better suited for cutting in certain tougher materials. You can read more about Sollex's qualities and coatings here.

Sollex offers a variety of utility blades that are suitable to cut and various materials. The universal utility blades are 59/61mm long and fit most knives on the market. Some of the blades have a coating on the edge, which makes them better suited for cutting in certain tougher materials. You can read more about Sollex's qualities and coatings here.

Sollex utility blades are adapted for our knives: Utility knife Mozart S2 1002.00, Construction knife 2000 and Dolphin knife 1280, but they fit most knives on the market.

Sollex Pro 975P trapezoidal utility blade is a professional-grade blade that performs better and lasts longer than most other blades on the market. The blade is specifically designed to cut drywall, gypsum board, carpet, and linoleum used by construction professionals.

If you work with flooring, we suggest Sollex Pro Titan 975PT. When cutting floor mats and linoleum, the titanium coating on the blade offers unsurpassed durability. Since the blade's edge is titanium-covered, the titanium shields it from harm prior to edge wear-down. For linoleum flooring, paper, and industrial materials, the long blade Sollex Pro-Titan 975PT is excellent. The Sollex Pro Titan 975PT's blade is unfortunately not the best at cutting drywall. Here the titanium breaks down the plaster and sits on top of the blade's covering like a membrane. The utility blade then thickens and cuts drywall slowly. However, the Sollex Pro Titan is ideal for cutting floor material or paper rolls.

If you work with flooring, we suggest Sollex Pro Titan 975PT. When cutting floor mats and linoleum, the titanium coating on the blade offers unsurpassed durability. Since the blade's edge is titanium-covered, the titanium shields it from harm prior to edge wear-down. For linoleum flooring, paper, and industrial materials, the long blade Sollex Pro-Titan 975PT is excellent. The Sollex Pro Titan 975PT's blade is unfortunately not the best at cutting drywall. Here the titanium breaks down the plaster and sits on top of the blade's covering like a membrane. The utility blade then thickens and cuts drywall slowly. However, the Sollex Pro Titan is ideal for cutting floor material or paper rolls.

For the most abrasive materials—fireproof gypsum, lead sheet, and reinforced flex and fiber-reinforced composite materials — we advise the Banzai 975B blade. Sollex's flagship utility blades are Banzai blades. Most likely the best heavy-duty utility blade you can buy for any kind of standard utility knife produced.

"Sollex Banzai is the sharpest utility blade I have ever tried," stated a customer in the printing industry. Sollex guarantees that this Banzai blade is the absolute best option for individuals who have the highest expectations for blade durability and performance, given their nearly 100 years of knife development experience.

The shorter utility trapezoid blade 50 to 52mm long is used when you want a lot of force on a blade edge and when you want to fix the blade as hard as possible in your handle. There are three general users of short trapezoid blades: floor installers, safety knives and industrial machines. Floorers use short straight knife blades to cut folds and to be able to cut smaller cuts in plastic and linoleum carpets. With the short robust design of the knife blade, maximum stability is given in the blade and the blade can be fixed tightly so that the gap for the knife blade is minimal. By that you get a very stable and robust grip on your blade. Some safety knives use short trapezoid blades such as 9H with a large hole, mainly because they are less pointed but at the same time give similar properties as ordinary knife blades in a universal knife. For mounting in machines, the short straight knife blade provides robust and stable cutting properties when a more robust blade is preferable compared to industrial razor blades.

The shorter utility trapezoid blade 50 to 52mm long is used when you want a lot of force on a blade edge and when you want to fix the blade as hard as possible in your handle. There are three general users of short trapezoid blades: floor installers, safety knives and industrial machines. Floorers use short straight knife blades to cut folds and to be able to cut smaller cuts in plastic and linoleum carpets. With the short robust design of the knife blade, maximum stability is given in the blade and the blade can be fixed tightly so that the gap for the knife blade is minimal. By that you get a very stable and robust grip on your blade. Some safety knives use short trapezoid blades such as 9H with a large hole, mainly because they are less pointed but at the same time give similar properties as ordinary knife blades in a universal knife. For mounting in machines, the short straight knife blade provides robust and stable cutting properties when a more robust blade is preferable compared to industrial razor blades.

Trapezoid utility blades are mainly used to cut carpets, plastics, cardboard, construction, and packaging materials. These universal knife blades fit most common construction knives and utility knives. Thanks to the 2-3 mounting jacks, you can relatively easily adjust how far the knife blade should protrude from the handle.

These utility blades are used by floor layers and craftsmen to cut:

These utility blades are used by floor layers and craftsmen to cut:

For industrial use, it is usually used in a machine that cuts plastic of a harder nature.

Sollex 9PT and 9-065-T carry titanium carbide on the blade edges. This means that a very thin layer of titanium covers the blade’s edge. The titanium protects the edge against abrasive wear and tear. The titanium is much harder than the steel, which gives good flexibility in the steel with high hardness on the cutting edge. For the right material, it means longer blade durability and retained sharpness.

The exception is if you cut gypsum boards, then the titanium tears the gypsum, which then sticks more easily to the titanium coating. So if you are going to cut plaster, you should choose article: 975P or 975B.

To cut carpets, felt, laminate, fabric, cardboard and cardboard, we strongly recommend that you use our knife blade or trapezoidal knife blade 9PT and 975P, 975PT.

If you need a short universal blade with a large hole, 9H is suitable for safety knives and to be mounted I industrial machines. 9PT or 9-065-T usually works very well for cutting plastic of a harder nature. If you are looking for the cheapest possible knife blade, knife blade 9P or 913 (slightly thinner) is a good alternative.

Sollex short utility knife blades are all delivered in plastic dispensers of 10 knife blades. These are packed in a box of 10 dispensers which in turn are packed in a box with ten boxes. Suitable to order are even hundreds or thousands. The box for Sollex Pro Titan is in Aluminum to provide the best possible storage of your Trapezoid or Utility Blades.

Sollex short utility knife blades are all delivered in plastic dispensers of 10 knife blades. These are packed in a box of 10 dispensers which in turn are packed in a box with ten boxes. Suitable to order are even hundreds or thousands. The box for Sollex Pro Titan is in Aluminum to provide the best possible storage of your Trapezoid or Utility Blades.

Sollex has been delivering utility blades quickly and safely since 1927. You can read more about our product qualities and coatings at product qualities. Can't find what you're looking for? Get in touch with us at +46 35-157500, and we'll help you!

Sollex utility blades - Cutting Edge Performance

Standard knives that are in stock will be shipped the same day if an order is placed before 1 pm on weekdays. Within Sweden, delivery takes one to two business days with Schenker. Two to five working days inside Europe with UPS. Our goal is always to deliver to your address as quickly as possible.

You will be given a delivery time, which typically ranges from 4 to 9 weeks, if you request customized machine knives or industrial blades that are not in stock at the time of purchasing. Find Sollex Purchase & Delivery Conditions here.

All first orders from new customers are prepaid. Further orders can be paid by invoice with 30 days payment term.

Once your order is confirmed and shipped, you will receive a tracking number, which you can track.

Sollex primarily sells machine knives of standard size and form that comply with the EOM. Industrial knives are available in a variety of forms, including top dished, bottom circular knives, serrated / toothed knives, circular perforating knives, straight knives, guillotine knives, pointed tip knives, rectangular razor blades, and trapezoidal blades.

We do, however, create bespoke knives of non-standard size and shape when a drawing or explicit request is provided. For example, we can manufacture solid tungsten carbide machine knives in a variety of non-standard forms with ultra-precise and extreme tolerances, which is very useful in the MedTech industry.

When contacting a knife manufacturer to order knives for machines and slitters, providing accurate inquiries and detailed information is critical to ensure you receive industrial knives that meet the needs of your slitting, converting operations and the material you will be cutting.

If you are ordering custom machine knives from Sollex, make sure you know the exact knife dimensions, material and mounting specifications. A drawing and a worn sample for analysis are useful. If not available a photo with clear dimensions can work. Identify in your request the current cutting problems you are currently experiencing with the cutting knife you are seeking to replace. If in doubt, our experts can help you find the right knife based on your machine model and cutting needs.

To help you pick the best blade, Sollex may give you several sample blades to test in production. For cutting and converting flexible materials like plastic film, foil, vinyl, paper, and others, we provide converting blades including slotted slitter blades and razor blades with three slots. Send us a query if you're interested in machine blades, and we'll provide you with an offer. Samples for custom-made knives are not available but you are most welcome to order the minimum order quantity.

Actually, our clients and industry partners often place recurrent orders for industrial knives with predetermined delivery dates. We ensure your production process runs well by manufacturing and delivering machine knives and blades on schedule. The most important thing is to tell us the volume of required knives and deadlines and we will prepare a warehouse supply guarantee.

Sollex sales may technical assistance and guidance on choosing a slitting knife in addition to assessing and creating the best cutting solution for your application. You can consult via phone, mail, or video conference. To do this, send an email to order@sollex.se.

Read our policy on returns and claims on the “Complaint & Return” page.

There are a number of ways that will prolong the longevity and shelf life of your industrial knives and blades in stock. Read about how proper packaging of machine knives, storage conditions, humidity and air temperature, and additional coatings will protect your knives and maintain their cutting performance here.

JavaScript seem to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.