Tungsten Carbide and Technology: Part 2

On the topic of "Tungsten Carbide Tools to Customer Drawings with Extreme Tolerances and Surface Characteristics" we have prepared a series of blog posts. We started by talking about the amazing material tungsten carbide, its properties and applications in the post "Tungsten Carbide - Properties and Applications of Tungsten Carbide". You can read the following parts "Tungsten Carbide and Technology" and "What Kind of Tungsten Carbide Does Sollex Use" on our blog.

Thermal and Electrical Conductivity of Tungsten Carbide

Tungsten carbide typically has a high thermal conductivity. Thermal conductivity is the ability of a material to conduct heat energy. Tungsten carbide is composed of metallic carbide particles that are bonded together by a metallic binder, which gives the material a high thermal conductivity. Therefore, carbide is used in applications where high heat resistance and thermal conductivity are required. For example, tools for cutting, drilling and milling metallic materials. However, the exact thermal conductivity can vary depending on the composition of the carbide and the manufacturing process.

Electrical conductivity is generally low because carbide is a non-metallic compound. However, the small amount of binder in the carbide may have some conductivity. This is not normally an important property for the use of carbide in cutting tools.

How Does Tungsten Carbide React to the Temperature?

Carbide has a high melting point and is therefore resistant to high temperatures. The most common type, with tungsten carbide and cobalt binder, has a melting point of approximately 2,870°C. This allows carbide to be used at high cutting speeds and in applications that are exposed to high temperatures, such as cutting tools for machining metals and composites.

To handle the high temperatures encountered in injection molding, it is also important that carbide tools have high temperature resistance. This is particularly important for tools used to injection mold thermoplastics, as these materials require higher temperatures to melt and flow well.

Tungsten carbides may loose hardness at high temperatures, as their binder (cobalt) may begin oxidizing and form a layer on their surface, weakening them. In addition, thermal expansion at high temperatures can cause stresses in the material and lead to cracking. As a result, the use of tungsten carbide at consistently high temperatures needs to be handled with care.

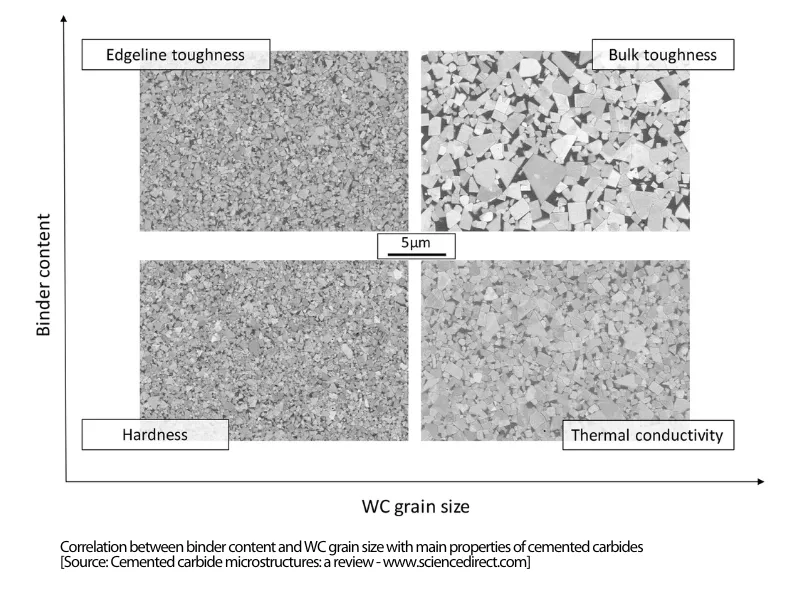

Tungsten Carbide and Grain Size

The grain size of the carbide has a significant effect on the hardness of a metal. In general, smaller grain sizes tend to produce harder metals. This is because smaller grains mean more grain boundaries, which act as barriers to dislocation movement. This prevents the movement of defects through the material.

In metallurgy, a common method of controlling grain size is heat treatment. When a metal is heated to high temperatures and then slowly cooled, the grains tend to grow larger. Conversely, if a metal is cooled rapidly, the grain size will be smaller.

Cemented Carbide Injection Mold Tooling Extreme Surface Characteristics

Tungsten carbide surface finish tolerances are dependent on several factors including machining technique, tool geometry and specific material. In general, however, very high surface finishes can be achieved with carbide.

For grinding cemented carbide tools, a normal surface finish tolerance is around Ra 0.4 micrometers (μm). It is important to note that surface finish tolerances are often given as a range, with the lower limit being the lowest possible surface finish and the upper limit being the maximum allowable surface finish. Surface finish tolerances on tungsten carbide can be very tight, sometimes as tight as ± 0.1 μm for some critical applications. Sollex has supplied injection molds with surface finishes of Ra 0.01 microns (μm).

Extreme Tungsten Carbide Mold Tolerances

Cemented carbide molds must have high precision and extremely fine tolerances because injection molding is a process where exact tolerances are important. Tight tolerances such as +/- 0.005 mm are encountered in injection molding of tungsten carbide tools. Sollex has supplied carbide tools with half this tolerance range: +0 and -0.005. This means that the tools are manufactured with high precision to ensure that they can produce high-quality products.

Achieving these extreme tolerances requires advanced manufacturing techniques such as high-speed machining and grinding. It also requires careful quality control and measuring tools to ensure that tolerance requirements are met.

Tungsten Carbide Radii and Radial Transitions

Radial transitions in cemented carbide refer to the rounded corners that are created when a cemented carbide component is turned or milled. These transitions are important to ensure that the component will not break or crack in service.

They are important to consider when designing and manufacturing carbide components because they can affect the hardness and strength of the material. Too large a radial transition can result in weakening of the component, while too small a transition can result in damage to machine tools and tools.

It is also important to consider material selection and turning parameters such as cutting speed and chip thickness to avoid damage to the tools or the finished component.

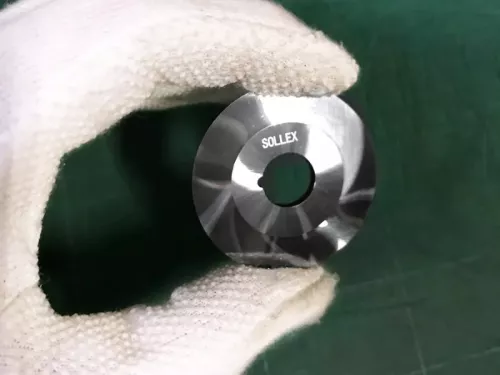

Mirror-like Polishing Treatment of Tungsten Carbide Tools

Mirror polishing is a surface treatment process used to produce a high gloss, mirror-like finish on various materials, including tungsten carbide. The process typically involves several stages of grinding and polishing to remove all scratches, marks, and imperfections from the surface.

Mirror polishing is a surface treatment process used to produce a high gloss, mirror-like finish on various materials, including tungsten carbide. The process typically involves several stages of grinding and polishing to remove all scratches, marks, and imperfections from the surface.

In order to achieve a mirror-like finish on tungsten carbide, it is important to choose the right type of abrasive and polishing media. These abrasives are usually diamond or silicon carbide-based and come in different grit sizes depending on the stage of the process for which they are being used.

After grinding and polishing, it is important to thoroughly clean the surface to remove any residual grinding and polishing media and other contaminants. This can be done using various types of detergents or ultrasonic cleaning.

Mirror polishing is usually a time-consuming and costly process but can produce a very high-quality surface that is both aesthetically pleasing and has good functional properties such as high wear and corrosion resistance. As a result, it is a popular process for improving the appearance and performance of tungsten carbide products in a variety of industries.

In machining, it is sometimes essential to have a polished or mirror-like edge. This ensures that the material is cut rather than torn. Similarly, when molding, polishing affects how the plastic material adheres to the carbide.