Slitting Methods: Razor Slitting with Industrial Razor Blades

Types of razor slitting technique, industrial slitting blades

In this article, we will discuss a common industrial cutting method such as razor blade slitting.

Content:

- What is razor slitting?

- Types of razor slitting technique

- What are the advantages of the razor slitting method?

- What kind of blades are used for razor slitting?

- Industrial razor blades for film and foil slitters

- Coated industrial razor blades

- Which industrial razor blade fits my goals?

What is Razor Slitting?

Generally when cutting (slitting) flexible materials 3 kinds of slitting methods are used: razor blades, shear cutting and crush cutting. Razor slitting is a method used to cut materials into narrow strips or sheets using an industrial razor blade. It can produce precise cuts with minimal waste and is well suited for applications that require high accuracy and consistency. Razor slitting can be easily adapted to almost any slitting process.

Generally when cutting (slitting) flexible materials 3 kinds of slitting methods are used: razor blades, shear cutting and crush cutting. Razor slitting is a method used to cut materials into narrow strips or sheets using an industrial razor blade. It can produce precise cuts with minimal waste and is well suited for applications that require high accuracy and consistency. Razor slitting can be easily adapted to almost any slitting process.

Razor slitting is often used for high-speed cutting of thin and flexible materials and fits best for slitting and converting packaging plastic films, aluminium foil, non-woven materials. Choosing the right razor blades makes a huge difference. We have been involved in tests where razor blades didn't last even 3 minutes. But if the same blade was coated with an additional coating, it lasted 4 weeks cutting the same material.

However, razor cutting has some limitations. It may not be suitable for thicker or tougher materials, and the blades may require frequent replacement due to wear and tear. In addition, the process may generate dust or debris that must be properly removed to avoid contamination or other problems.

When the web material is drawn past a stationary razor blade, a cut is produced. The resulting cut depends on the characteristics of the web material. These include thickness, density, stiffness, ductility, coating, and other factors. When razor slitting, the material is unwound from the roll, passed through the razor blades, cut in air or in a grooved roll, and finally wound onto cores called spools or bobbins.

Types of Razor Slitting Technique

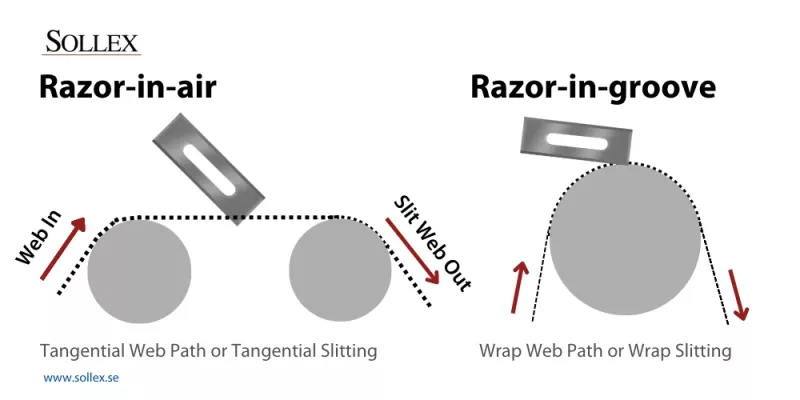

There are two main types of razor slitting: slit in the air or razor-in-air (top mounted) and slit in a grooved roll or razor-in-groove (bottom mounted). The first type requires no extra support at the slitting area and is better for slower speeds. The second one uses a roll with grooves that provide additional support at the point of slitting for higher running speeds.

Razor blades are mounted at an angle in razor blade holders to slit the moving web. The angle of the blade is important because it affects the quality of the cut. If the angle is too shallow, the material may tear or become jagged. If the angle is too steep, the blade may cause excessive friction and wear out quickly.

What are the advantages of the razor slitting method?

There are several advantages associated with the razor slitting method.

High precision | Razor slitting can produce very precise cuts with minimal waste. The blade can be positioned at a very specific angle to achieve the desired cut, allowing for greater accuracy. |

High-speed cutting | Razor slitting is a high-speed cutting method that can produce a large volume of cut material quickly and efficiently. This is especially useful for industries that require high-volume production, such as paper and plastic manufacturing. |

Minimal burrs | Because razor blades are very sharp, they produce very few burrs or jagged edges, which can reduce the amount of post-processing required after cutting. |

Versatility | Razor slitting can be used to cut a wide range of materials, including paper, plastic, rubber, textiles, and more. This makes it a versatile cutting method that can be used in a variety of industries. |

Low tooling costs | The equipment used for razor slitting is relatively simple and low-cost, which can help reduce overall production costs. |

Consistent quality | Razor slitting can produce consistent, high-quality cuts, which can improve the overall quality of the finished product. |

Overall, the razor slitting method is a highly effective cutting method that can provide numerous benefits in terms of precision, speed, versatility, and cost-effectiveness.

Nevertheless, the razor slitting method not optimized to cut rigid, heavy or extremely abrasive materials. Wrong razor blades may generate enough heat to melt film or create a bead which is detrimental to achieving good roll edges. Besides, although the razor blades are of low cost, they need to be frequently changed to ensure a good quality slit edge.

You can also read about 13 common problems with cutting plastic film, and what you can do about them in our blog article.

What kind of blades are used for razor slitting?

Industrial razor blades are used for razor slitting in slitter or converter machinery. These blades are thin, straight slitting blades optimized for cutting narrow strips of material. Industrial razor blades are used in various manufacturing and processing industries to cut through different materials such as paper, plastic film and foil, stretch wrapping film and other soft materials. Industrial razor blades are typically made of high-quality steel or other durable materials, such as tungsten carbide, ceramic, that allow them to withstand heavy usage and produce precise cuts over long periods.

Synonyms for industrial razor blade: industrial cutter blade, film slitting blade, converting blade, razor slitter, three-hole double edge slitter, Three Holes Razor Slitter Blades, 3-hole slitter blade, 3-hole industrial razor blade, film slitting blade, rounded end 3-hole slitter, slotted blade

Industrial Razor Blades for Film and Foil Slitters

For plastic film manufacturers, we offer a number of different industrial blades:

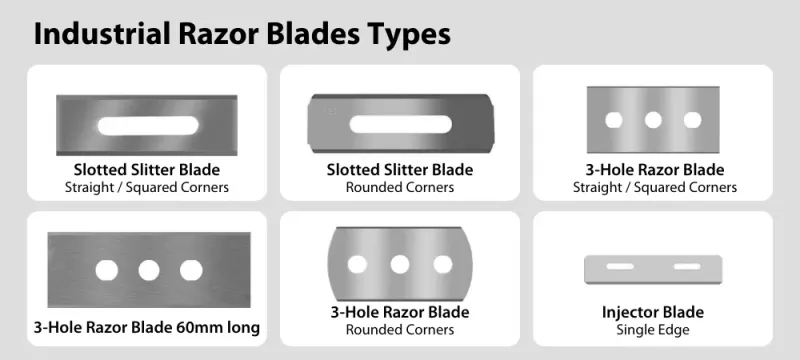

1. Slotted slitter blades. They come with straight or rounded corners. Thickness of such slitter blades are 0.40 mm and 0,20mm. Standard blade size is 57x19x0.40mm.

2. 3-hole industrial razor blades. Such slitting blades also come with straight and rounded corners. The blade sizes are as follows:

- 43x22x0.13 mm

- 43x22x0.15 mm

- 43x22x0.20 mm

- 43x22x0.30 mm

- 43x22x0.40 mm

- 43x22x0.40 mm

- 43x22x0.20 mm

3. Injector blades. These are small industrial blades, usually sized 38x8x0.25mm. They have 2 holes for mounting in the slitter machine.

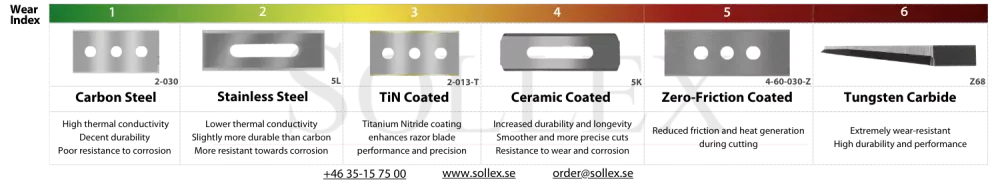

Sollex industrial blades are available in the following materials and coatings

Sollex industrial blades are available in the following materials and coatings

- Tool Steel

- Stainless Steel

- Carbon Steel

- Solid Tungsten Carbide

- T - TiN Titanium Nitride

- Z - Zero Friction

- K - Ceramic coating

- X - Full Ceramic coating

Solid tungsten carbide slitting blades are used for heavy duty applications, thick flexible materials, highly abrasive films, or plastic films with additives.

Additional coating of the cutting edge is used to extend blade life while reducing friction between the web material and the slitting blade. Coated cutting edges make them smoother and last longer than rough blades that are not coated.

Read more about coating for industrial razor blades here

Coated Industrial Razor Blades

Ceramic coated industrial blades are a type of razor blade that has a ceramic coating on the cutting edge. The ceramic coating is designed to improve the performance and durability of the blade.

Coatings is a hard, wear-resistant material that can provide a number of benefits in industrial cutting applications. Some advantages of ceramic coated industrial blades include:

- Increased durability. Ceramic coatings are extremely hard and wear-resistant, which can help extend the life of the blade. This can result in fewer blade changes, reducing downtime and production costs. This means that the blade can cut through materials more effectively, without becoming dull or damaged as quickly.

- Reduced friction. Ceramic coatings can reduce the amount of friction between the blade and the material being cut. This can help prevent the material from sticking to the blade or causing heat buildup, which can result in better quality cuts and less wear and tear on the blade.

- Better corrosion resistance. Ceramic coatings are also highly resistant to corrosion and oxidation, which can help protect the blade from rust and other forms of corrosion.

Ceramic coated industrial blades are mainly used in plastic film manufacturing, where high precision cutting and durability is critical.

Sollex industrial blade with ceramic coating has “-K” in the ending of a product article. The slitting blades are available in a range of thickness and designs (there are razor blades with rounded and squared corners, with slotted or three holes etc) to suit specific cutting applications, and can provide a cost-effective solution for industries that require high-quality, long-lasting cutting tools.

Sollex industrial blade with ceramic coating has “-K” in the ending of a product article. The slitting blades are available in a range of thickness and designs (there are razor blades with rounded and squared corners, with slotted or three holes etc) to suit specific cutting applications, and can provide a cost-effective solution for industries that require high-quality, long-lasting cutting tools.

Which industrial razor blade fits my goals?

Sollex has high quality industrial razor blades for any kind of application. Our industrial-type razor blades are made of high-chromed carbon steel, stainless steel, solid tungsten carbide, zirconia ceramic and additional coatings of the blades are our strength.

If you do not find the razor blade you are looking for, Sollex are able to manufacture industrial razor blades according to your drawing.

Feel free to contact us at +4635-15 75-00 if you have any questions regarding our industrial razor blades.