Slitting Blades for Macchi Extrusion Lines

Macchi Extrusion Lines for Plastic Film Production

Macchi has been manufacturing blown film extrusion lines for over sixty years. Their plastic extrusion lines are trusted by film producers around the world for their flexibility and ability to handle a wide range of materials. Whether it’s standard mono-layer polyethylene films or complex multilayer barrier structures, Macchi extrusion lines are built for high productivity and tight process control.

Macchi has been manufacturing blown film extrusion lines for over sixty years. Their plastic extrusion lines are trusted by film producers around the world for their flexibility and ability to handle a wide range of materials. Whether it’s standard mono-layer polyethylene films or complex multilayer barrier structures, Macchi extrusion lines are built for high productivity and tight process control.

Today, Macchi offers a full range of extrusion technologies, from the new POD and R-POD FLEX series optimized for flexible and food packaging, to COEX FLEX lines designed for multilayer film production in three, five, seven, or even nine layers. Macchi Agrifilm extrusion line technology is used for extruding agricultural-use plastic films like greenhouse and silage films with high mechanical performance and parameters. Supporting these extrusion lines are BO Series winders for precise roll handling, Recotrim for edge trim recovery, and Easy Control Plus 4.0 for advanced line management.

Macchi manufacturing and converting machinery is widely used for agricultural films, shrink films for bundling, wide web production, flexible and food packaging, and films for web converting applications like lamination and printing. Here's a quick technical overview of Macchi’s blown film solutions:

Macchi Machinery | Purpose / Application |

|---|---|

POD and R-POD FLEX Series | Flexible packaging films, food packaging, collation shrink films |

R-POD FLEX | Enhanced flexibility and output for food-grade and industrial films |

COEX FLEX 3 | 3-layer extrusion for standard multilayer packaging |

COEX FLEX 5, 7, 9 | High-performance multilayer lines for advanced barrier films |

Agrifilm | Wide agricultural films (greenhouse covers, silage films) |

BO Series Winders | Winding solutions for tension-controlled film rolls |

Recotrim | Inline trim recovery and material recycling |

Easy Control Plus 4.0 | Digital extrusion control for stability and optimization |

Cutting, Slitting & Converting

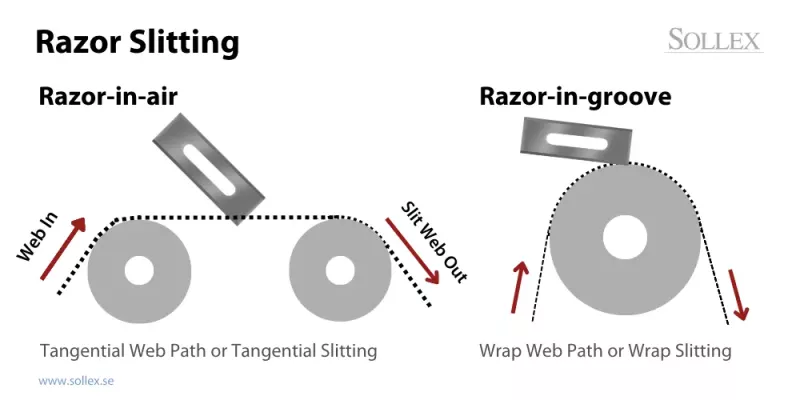

Extruding high-quality plastic film is only part of the process. After the film bubble is formed and flattened, it must be slit, trimmed, and wound into rolls with perfect edge quality. This is where cutting performance becomes critical. Poor or inconsistent cuts lead to frayed edges, material waste, downtime, and customer complaints. Even the best extrusion technology cannot compensate for damage caused during slitting and trimming.

Read more about common cutting problems in our blog, “13 common problems when slitting and cutting blown film, and what you can do about them”. These issues slow down production and increase post-industrial plastic waste.

For manufacturers running any blown film extrusion lines, including Macchi systems, choosing the right industrial razor blades for slitting, converting, and edge trimming is essential for effective plastic film manufacturing.

Sollex Blades for Plastic Film Slitting and Converting

Sollex supplies industrial razor blades designed for plastic film production and converting. Our blades are adapted for the high demands of blown film extrusion, providing sharp, stable cuts at high line speeds across a wide range of film structures. For mono-layer and thin LDPE or LLDPE films, Sollex stainless steel blades deliver excellent sharpness and clean edges. For tougher barrier films or abrasive multilayer laminates, Sollex tungsten carbide blades offer longer life, better durability, and consistent cutting performance, even in demanding environments.

We’ve worked with many customers running Windmöller & Hölscher, Reifenhäuser GmbH & Co. KG Maschinenfabrik, Macchi, Costruzioni Meccaniche Luigi Bandera S.p.A equipment, and certain Sollex blades keep coming up as top choices:

We’ve worked with many customers running Windmöller & Hölscher, Reifenhäuser GmbH & Co. KG Maschinenfabrik, Macchi, Costruzioni Meccaniche Luigi Bandera S.p.A equipment, and certain Sollex blades keep coming up as top choices:

- 5Z / 5LZ slotted razor blade: a unique zero-friction-coated razor blade perfect for reducing dust and heat in the cut and handles PE, LDPE, LLDPE, HDPE, BOPE,PET, PIR, PCR films well

- 5K slotted razor blade: a reliable, ceramic-coated razor blade for general-purpose film slitting

- 5T slotted razor blade: long-lasting blade with titanium TiN cutting edges for slitting PE and PET polymer films

- 2-020-Z or 2-030-Z 3-hole razor blade: slitting blades with zero-friction coating as thinner alternatives to 5Z blades

- 2-020-K or 2-030-K 3-hole razor blade: converting razor blades with ceramic coating as thinner alternatives to 5K blades that can slit a wide range of films

- 4-60-030-Z long 3-hole razor blade: coated slitting edges with ceramic for extreme durability, ideal for high-speed lines or abrasive films

Each of these models has proven to perform well in blown film and cast film systems, especially when the goal is high throughput and consistent edge quality.

When used on Macchi extrusion lines, Sollex blades help operators achieve smoother roll edges, reduce material waste during trimming, minimize blade changeovers, and maintain higher winding speeds without sacrificing cut quality. This leads directly to better roll formation, lower scrap rates, and higher overall efficiency in film production.

Download PDF with Sollex Blades for Plastic Industry

Cutting Quality Defines Production Quality

Reliable cutting is not a small detail in film extrusion. It directly impacts machine uptime, material efficiency, roll quality, and customer satisfaction. In tight production schedules, every lost meter of film matters. The combination of Macchi’s advanced extrusion technology and Sollex industrial slitter razor blades gives producers the tools they need to run stable operations, produce better films, and stay competitive. If you are running Macchi blown film equipment and want to optimize your plastic film slitting and converting operations, Sollex can support you. With the right choice of industrial razor blades, you can unlock the full potential of your extrusion lines and improve both process stability and product quality.

Contact Sollex today to find the right blade solution for your Macchi production setup.