Industrial Injector Razor Blades: Basics

About Industrial Injector Razor Blades

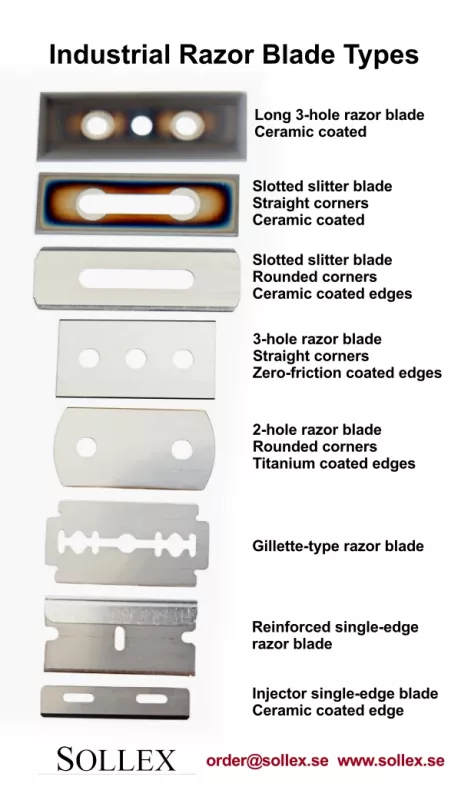

Industrial slitter blades that are thinner than 0.40mm are called industrial razor blades. Injector blades are considered to be one type of such blades. Injector razor blades are the smallest blades when compared to 3-hole razor blades, slotted slitter blades and others. They also have only one cutting side for industrial cutting of flexible roll materials in-line or converting roll materials such as plastic film, foil.

Industrial slitter blades that are thinner than 0.40mm are called industrial razor blades. Injector blades are considered to be one type of such blades. Injector razor blades are the smallest blades when compared to 3-hole razor blades, slotted slitter blades and others. They also have only one cutting side for industrial cutting of flexible roll materials in-line or converting roll materials such as plastic film, foil.

The industrial significance of injector blades lies in their unique design and functionality, which contribute to efficiency and performance in various processing applications. The size of the injector blade makes it perfect to fit into small areas where larger 3-hole blades or slotted slitter blades do not fit. So if you need a small blade because you lack space, the injector blade is a right choice.

Injector blades for shaving vs. industrial injector blades for slitting

Injector blades were invented as an evolution of the three-hole blade, as a solution to use less steel to produce shaving blades. Today, Schick still supplies injector blades for shaving. Schick, officially known as Eversharp, manufactured injector blades in the old Matador factory in Halmstad, Sweden until it closed in 1977. Because Eversharp-Schick injector blades are “relatively thick,” they require a sharp three-bevel sharpening for a clean shave. Industrial injector blades are less sharp, but much more durable than shaving variants. Basically, they last longer.

Industrial slitting & converting with injector blades

As with other types of industrial razor blades, when the web material is pulled past the stationary injector razor blade, a cut in the material is generated. The resulting cut depends on the characteristics of the blade and the web material. These include thickness, density, stiffness, plasticity, coating, and other factors. During the conversion process, the material is unwound from the roll, passed through the injector blades, cut in the air, and rewound onto bobbins narrower than the original roll.

Features, Grinding and Performance of Injector Blades

Dimensions of Injector Blades

The standard size of injector blades is 38x8mm and blade thickness is 0.25mm. Injector razor blades have 2 slots for locking into the blade holder in the slitter machine. Injector-type industrial blades have grinding on both sides of the blade, however, they only have 1 cutting side. The grinding angle of these small single-edge razor blades can be single, double and triple bevel sharpened.

The standard size of injector blades is 38x8mm and blade thickness is 0.25mm. Injector razor blades have 2 slots for locking into the blade holder in the slitter machine. Injector-type industrial blades have grinding on both sides of the blade, however, they only have 1 cutting side. The grinding angle of these small single-edge razor blades can be single, double and triple bevel sharpened.

What materials are injector blades made from?

Injector blades are typically made of stainless and carbon steel. Stainless steel injector blades make up the majority of Sollex's product line. However, we can also produce injector blades using solid tungsten carbide and zirconia ceramic (642C).

When are stainless steel injector blades mainly used?

Most plastic tools for cutting use industrial stainless steel injector blades as a component.

Edge coatings for injector razor blades

Additional coatings enhance the features and performance of machine knives and slitting blades. Edge coating is one of many ways, like polishing, that improve cutting in many time. Read about 3 more ways to improve slitter knife performance in our blog article “4 Ways to Improve Slitter Knife Performance”.

For industrial razor blades, such as single-edge injector razor blades, the coating protects the blade's cutting edge. The industrial coating is extremely hard, and the steel is flexible. This combination gives long endurance and performance when under abrasive slitting and cutting. With the small dimensions of the injector blade, you are able to get really long-lasting blades in machines where there is practically no space.

Cutting performance and durability is often improved with additional coatings on the cutting side of the industrial blade, such as ceramic coating, titanium coating, and others. Sollex offers injection blades with the ceramic-coated 642K and the unique Zero Friction coating - 642Z. The coated cutting edge of the injector razor blade is protected from heat and abrasion; wear and tear durability is improved.

It should also be noted that blade coating not only improves the blade features and its endurance, but also the quality of the cut, the cutting edge, and the final result.

Ceramic coated injector razor blades

When are ceramic-coated injector blades good to use? Ceramic-coated razor blades are very well suited for cutting and slitting white plastic film. Essentially, these blades are designed to cut through calcium carbonate-containing film (chalk, limestone, marble). The ceramic coating prolongs durability and is also very common when cutting paper material.

When are ceramic-coated injector blades good to use? Ceramic-coated razor blades are very well suited for cutting and slitting white plastic film. Essentially, these blades are designed to cut through calcium carbonate-containing film (chalk, limestone, marble). The ceramic coating prolongs durability and is also very common when cutting paper material.

Ceramic-coated blades are Sollex blades with “K” in the article number.

Zero-friction coated injector razor blades

When are zero-friction-coated injector blades recommended for use? Zero-friction coated injector razor blades are very well suited for cutting and slitting thin plastic film at high speed. The zero-friction coating generates a minimal amount of plastic adhesion to the edge and side of the razor blade. In our experience, the best injector razor blades for slitting thin plastic film as cleanly as possible are those with zero-friction coating.

Zero-friction blades are Sollex blades with “Z” in the article number.

Zirconia ceramic injector razor blades

When are solid zirconia ceramic injector blades the smart choice? Solid zirconia ceramic injector blades are white heavy-duty single-edge razor blades optimal to cut and process very abrasive materials. The solid ceramic material is regrinded during the cutting process, making it more durable when cutting tough materials.

Fully ceramic blades are Sollex blades with “C” in the article number.

Sollex supplies injector blades for slitting and converting

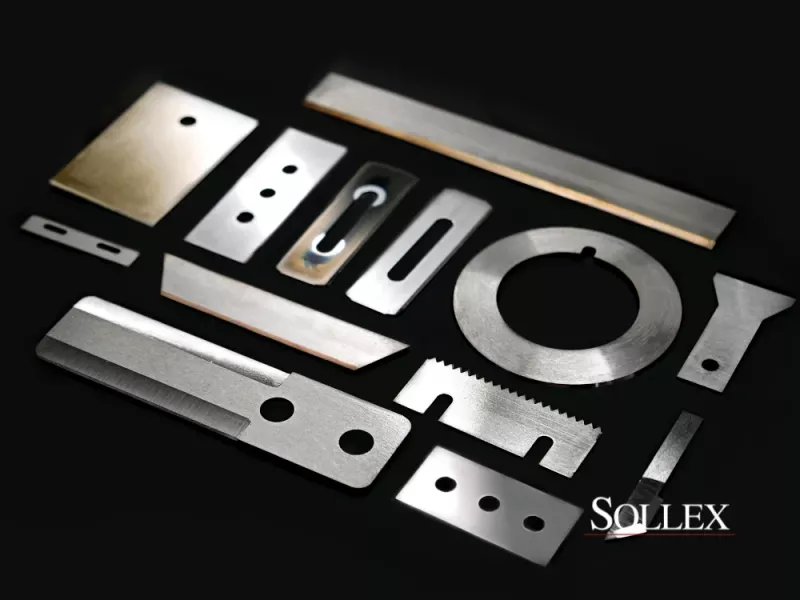

Sollex offers high-quality industrial razor blades for any application. Our industrial razor blades are made from high chrome carbon steel, stainless steel, solid tungsten carbide, zirconium ceramic, and additional blade coatings are our strength.

If you don't find the blade you need, Sollex can manufacture industrial blades to your drawing.

If you have any questions about ordering or product specifications, please contact us at +4635-15 75-00 or order@sollex.se.