Roll-To-Roll Slitting of Flexible Materials

Slitting as a Part of Roll-to-Roll Processing

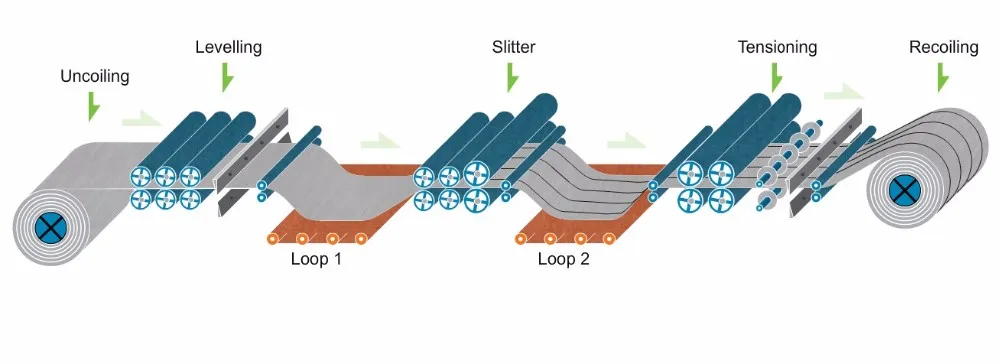

Raw rolls of flexible materials usually need to be roll-to-roll (R2R) processed and cut into smaller individual rolls to become a finished product which can be commercialized. Roll-to-roll processing of flexible materials involves a variety of converting activities including printing, laminating, and coating, but the primary activity is cutting and slitting.

Longitudinal rewind slitting on a slitter rewinder machine is most commonly used to process coiled materials, but there are also types of cutting such as lathe log cutting and die cutting.

The following flexible material types are the often slit with rewind slitting method:

- Polyethylene (PE), polypropylene (PP), polyester (PET), stretch film, recycled PCR film, and vinyl (PVC) are examples of plastic films that are used for packaging, laminates, protective and decorative wraps, and signs

- Aluminum foil for use in lithium battery manufacturing, insulation, and food packaging

- Paper and paperboard, cardboard, kraft paper for packaging, release liners for tapes, tissue paper for hygienic purposes, etc.

- Pressure-sensitive adhesive (PSA) tapes for making electrical, duct, and masking tapes are examples of adhesive tapes and laminates

- Nonwoven materials, such as spunbond nonwoven fabric used in different industrial applications and healthcare and medical supplies

- Textile webs for clothing, car interiors, and filtration materials

- Polyurethane and polyethylene foam are examples of flexible foam materials used for packing, cushioning, and insulation.

- Rolls of rubber and elastomers, including silicone sheets for industrial use and rubber sheeting, among many others.

During the slitting process, the parent roll of flexible material is unwound and slit into parts of a given width, passing through a series of knives spaced at the appropriate distance - the width of the resultant smaller rolls. The most popular types of rewind slitting processes are razor cutting, crush cutting, and shear cutting.

Razor Slitting Overview

Razor slitting is simple and inexpensive to install and is commonly used to cut all types of plastic films, vinyl, tape, foil, paper, and non-woven materials. With razor cutting, material web can be cut at high speeds into very narrow strips, and relatively little dust is generated, making this one of the cleanest cutting methods available.

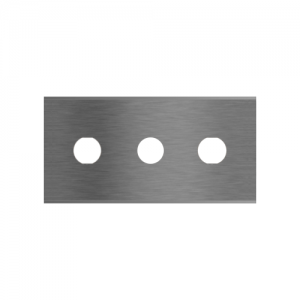

Blades used for razor cutting are inexpensive and yet require more frequent replacement than when shear or score cutting. Therefore, to mitigate this disadvantage, it is important to select the right slitter razor blades and blade holders for the material being cut well. The resulting slit depends on the characteristics of the material. This includes thickness, density, stiffness, plasticity, coating, and other factors. For fine, clean, non-abrasive material, carbon steel and stainless steel blades can be used. Otherwise, use blades with additional coatings, different thicknesses, and made of harder materials such as tungsten carbide. More about the razor slitting method read in our article, “Slitting Methods: Razor Slitting with Industrial Razor Blades”.

Check out our wide range of razor-cutting blades for flexible materials, plastic film, foil, paper, vinyl, tape, and non-wovens here.

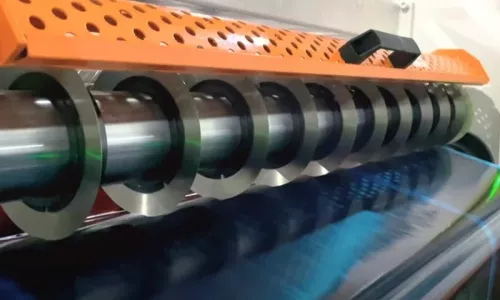

Shear Slitting Overview

Shear slitting handles a diverse array of materials, e.g. plastic films, foils, non-woven fabrics and textiles, rubber, adhesive tape, laminates with ease, making clean and precise cuts that are essential for the finished rolled material products. From the heavy-duty demands of thick polyester to the delicate touch required for thin foils, shear slitting adjusts its embrace to accommodate the unique properties of each material.

When slitting with the shear cutting method, the decisive factor influencing the cut quality and edge condition of the material is, in addition to quality and correctly selected knives, material speed, pressure, cutting angle, and also the correct setting of the intersection depth of the top and bottom knives. You will get poor cut quality and bulging edges if you set the intersection depth too high. If you program the depth too shallow, you will get interrupted edges and poor quality of the cutting process with many waste products. If you use circular top knives that are too small in diameter or knives with a worn cutting edge, which reduces the area of intersection between the top and bottom knife and the material and will result in a compromised, uncontrolled cutting process. More about the crush cutting method read in our article, “Shear Slitting: Precision Cutting Guide”.

Crush Knife Slitting Overview

Nonwoven textiles, tissue, rubber, laminates, multilayers, paper, abrasive materials, and sandpaper are all examples of thicker materials that may be score or crush cut. Although this rewind slitting method delivers the lowest edge quality, it is simple to set up and needs low-cost components. Furthermore, crush slitting will generate more dust while separating the material web into narrower strips.

The crush cutting uses a circular knife and an anvil roller, both hardened. The knife is not only ground after hardening, but the cutting edge is radiused and then polished. In slitting machines, the knife is kept in position by a pneumatic holder and moved by air pressure. During the slitting operation, the knife is pushed into the material and impacts a hardened anvil, separating the web of material.

More about the crush-cutting method read in our article “About Crush Cutting & Crush Cut Knives”.

Sollex is a Swedish supplier of industrial slitter razor blades and slitting machine knives to processing and converting industries all over the world! We provide cutting products that enhance production, cut inline or during roll-to-roll processing, and tackle cutting challenges. With the correct knives and blades, you can simplify maintenance, save time, and produce a higher-quality product.

You are welcome to contact us with your questions:

Company name: Sollex AB

Customer service and orders: order@sollex.se

Telephone: +4635–15 75 00

Adress: Box 5161, 200 71, Malmö, Sweden