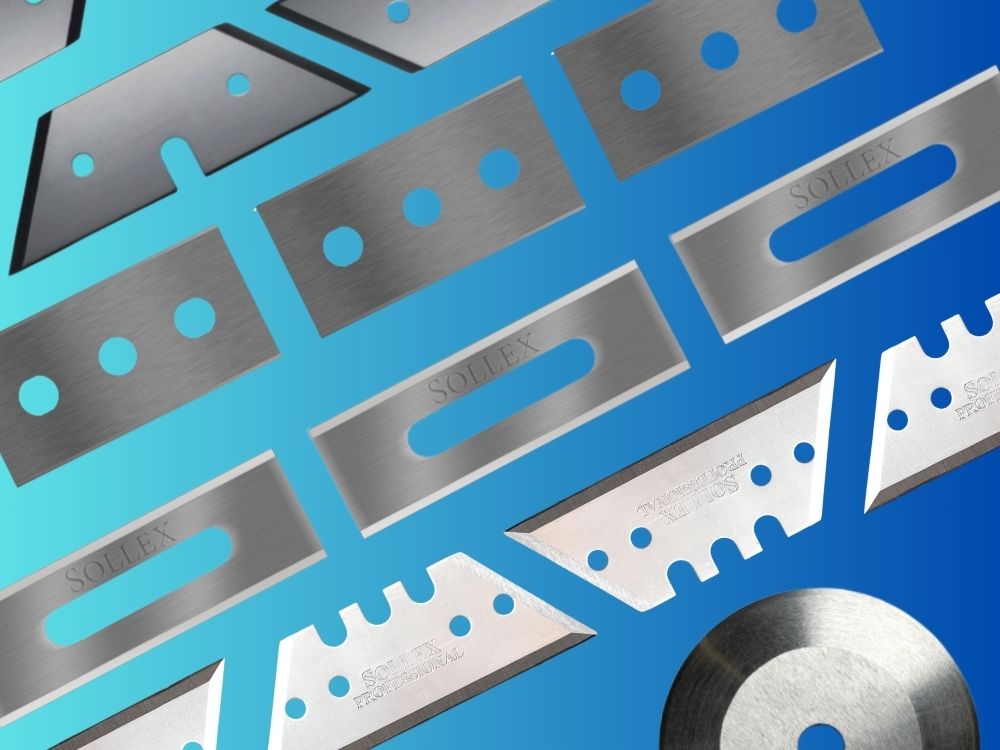

Overview: Tungsten Carbide Slitter Blades

Converting knives and industrial razor blades are made of materials such as carbon steel, high-speed steel, stainless steel, zirconia ceramic, tungsten carbide, and others. Each blade material mentioned has its own features and benefits when cutting web materials, so it is important to find the industrial blade that is right for your application. Choosing the right blade material for ensures maximum run time and blade life while creating perfect cuts.

In this article, we will talk about Sollex industrial knives and, in particular, razor blades made of solid tungsten carbide, as well as the benefits and features that are important to know. Razor cutting is a common method of cutting thin flexible materials, typically used for roll-to-roll processing and rewind slitting web materials such as plastic film, foil, vinyl, paper, and non-wovens.

Content:

- Ultra Durable Solid Tungsten Carbide Blades

- Radii and Radial Transitions

- Price of Tungsten Carbide Slitter Blades

- What You Need to Know When Using Tungsten Carbide Blades

- Best Applications of Tungsten Carbide Blades

- Sollex Tungsten Carbide Blades

Cemented Tungsten Carbide Razor Blade Characteristics

Tungsten carbide is a tough material that is used to make cutting tools, including slitting knives and rzor blades. Its structure is similar to that of concrete, with grains of tungsten carbide acting as grains and cobalt as a binder. The superfine grain size provides high hardness while maintaining strength. Cemented carbide is a material that typically consists of a mixture of tungsten carbide and a binder metal such as cobalt or nickel. Additional elements such as titanium and tantalum may be added to improve performance.

Ultra Durable Solid Tungsten Carbide Blades

Solid tungsten carbide shows exceptional hardness, providing significant resistance to wear and abrasion. This property enables machine knives and razor blades to maintain their sharpness for an extended duration compared to slitting blades made of softer alloys and steel grades. Solid tungsten carbide demonstrates also corrosion resistance and the ability to endure harsh environments.

Tungsten Carbide Radii and Radial Transitions

Radial transitions in cemented carbide refer to the rounded corners that are created when a cemented carbide component is turned or milled. These transitions are important to ensure that the component will not break or crack in service.

They are important to consider when designing and manufacturing carbide components because they can affect the hardness and strength of the material. Too large a radial transition can result in weakening of the component, while too small a transition can result in damage to machine tools and tools.

It is also important to consider material selection and turning parameters such as cutting speed and chip thickness to avoid damage to the tools or the finished component.

Price of Tungsten Carbide Slitter Blades

Tungsten carbide slitter blades are most often much more expensive than slitting blades made from other materials due to the higher cost of manufacturing of the first ones. You may notice that sometimes 10 pieces of tungsten carbide blades cost as much as 100 carbon steel blades. However, more often than not, it is more cost-effective to purchase tungsten carbide blades because they are more durable, sometimes x300 times. Therefore, do not jump to conclusions, but rather test the hard metal blades in practice.

What You Need to Know When Using Tungsten Carbide Blades

The elevated hardness of tungsten carbide contributes to its durability and precision in cutting applications; however, this characteristic also results in increased fragility of the blades. Inadequate handling of blades may result in chipping, splintering, or cracking. Installation of a cracked blade or excessive tightening of the set screw may result in the shattering of the tungsten carbide blade upon contact with the material being cut. Tungsten carbide blades exhibit non-magnetic properties, indicating that magnetic blade holders are incompatible for use with them.

Best Applications of Tungsten Carbide Blades

Solid tungsten carbide blades offer, as a rule, longer blade life compared to carbon steel, high-speed steel and stainless steel blades. Tungsten carbide blades especially excel in cutting high-density plastic films, multilayer films, laminated films, advanced film with layer of PE, PP, PET with additives such as TiN (titanium). In addition to durability, the superior hardness of tungsten carbide provides rigidity when handling, allowing precise, clean cuts to be made. So if you are a manufacturer of industrial, agricultural plastic films, multilayer films or films with a high content of masterbatches and additives, such as calcium carbonate, then industrial tungsten carbide slitter razor blades are worth a try in your production operations.

Sollex Tungsten Carbide Blades

Sollex is a supplier of industrial razor blades and machine knives in a wide range of materials and additional coatings. Solid tungsten carbide is used in the production of our cutting products, or it is applied as a coating to steel. This provides slitting knives and razor blades with extreme durability and exceptional cutting properties. Solid tungsten carbide in grades K30UF, YG10X, K30MG, and C40G is used by Sollex to make industrial-type knives, knife blades, industrial razor blades, and injection molding tools.

Sollex is a supplier of industrial razor blades and machine knives in a wide range of materials and additional coatings. Solid tungsten carbide is used in the production of our cutting products, or it is applied as a coating to steel. This provides slitting knives and razor blades with extreme durability and exceptional cutting properties. Solid tungsten carbide in grades K30UF, YG10X, K30MG, and C40G is used by Sollex to make industrial-type knives, knife blades, industrial razor blades, and injection molding tools.

Examples of industrial razor blades made of solid tungsten carbide:

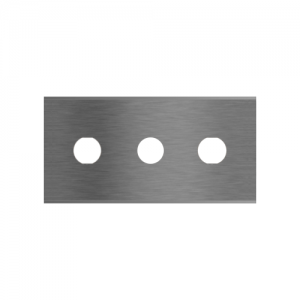

- 2-020-V / Straight 3-hole blade 0.20mm Solid Tungsten Carbide

- 2-030-V / 3-hole blade 0.30mm Solid Tungsten Carbide

- 5V / Slitter blade straight 0.40mm Solid Tungsten Carbide

- 4-100-V / Straight 3-hole-blade 100mm long solid tungsten carbide

Sollex examples of knives and tools in K30UF are:

- Z606 / Zund Z606 (5210312)

- 761V / Pointed blade 761 Solid Tungsten Carbide 10pcs

- 752V /Trapezoid blade like Martor no 752 10pcs

- Z53 / Rotary knife like Zund Z52/Z53 Ø32mm (3910337)

- Z68 / Zund Z68 (5204301)

TIP: All Sollex industrial knives with a “V” in the part number (except knives for CNC cutting tables and plotters) are made of solid tungsten carbide.

Our company manufactures cemented carbide knives and tools characterized by exceptional tolerances and surface finishes, leveraging our expertise in the production of finely and precisely ground surfaces in solid tungsten carbide. We possess comprehensive expertise in the design and production of radii and radial transitions utilizing cemented carbide materials. Additionally, we provide mirror polishing services for intricate surfaces.

To order tungsten carbide knives send us an email to order@sollex.se with your order details and we will send you a quote within an hour!

_____

On the topic of "Tungsten Carbide Tools to Customer Drawings with Extreme Tolerances and Surface Characteristics" we have prepared a series of blog posts. We started by talking about the amazing material tungsten carbide, its properties and applications in the post "Tungsten Carbide - Properties and Applications of Tungsten Carbide". You can read the following parts "Tungsten Carbide and Technology" and "What Kind of Tungsten Carbide Does Sollex Use" on our blog.