How to cut aluminium foil - Customer case

Blades for aluminium foil

Content:

- What are aluminium bags and sachets and what are they used for?

- How to cut aluminium foil

- General method of cutting aluminium foil

- Customer requirements for cutting aluminium foil sachets

- Sollex test lab for cutting aluminium foil

What are aluminium bags and sachets and what are they used for?

The sealed aluminium bag is the most common bag type for portion packs worldwide. Aluminium sachets are small, sealed packets of aluminium foil. The bag is suitable for products in liquid, paste and powder form. Aluminium foil sachets are often coated with plastic that does not react with the contents inside.

The sealed aluminium bag is the most common bag type for portion packs worldwide. Aluminium sachets are small, sealed packets of aluminium foil. The bag is suitable for products in liquid, paste and powder form. Aluminium foil sachets are often coated with plastic that does not react with the contents inside.

Aluminium foil bags are also recognized as a good solution for the following products, e.g:

- Medical devices, pharmaceuticals, dietary supplements

- Food

- Liquid detergents and disinfectants

- Hygiene products

- Cosmetics and others

Aluminium foil bags are robust and provide maximum resistance to dust, oxygen, chemicals, water, moisture and other substances that tend to degrade the quality of the stored product.

How to cut aluminium foil

A medical device company asked Sollex the following question: how to cut aluminium foil? In their case it was two layers of reinforced and welded aluminium foil in the shape of a sachet bag. That is, a bag of aluminium foil containing a liquid medical product.

General method of cutting aluminium foil

For best results in continuous cutting of aluminium foil, the blade should be as thin as possible and the attack angle should be 45 degrees. The aluminium foil must be tensioned or stretched, otherwise it will not work. Cutting aluminium foil at high speed means that you need to start cutting the foil at the edge with a straight sharpened blade.

Customer requirements for cutting aluminium foil sachets

Sollex customer wanted to understand how to design the blades to cut double-weighted, welded and reinforced aluminium foil.

The customer had two starting points:

- To cut with a serrated knife or with a straight-edged knife.

- Since the material in the sachet bag was liquid, the knives needed to be stainless to avoid rust.

The customer primarily wanted help in recommending a 1mm and 2mm stainless steel serrated knife. Long service life was very important to minimize maintenance costs and replacement time. The serrated knife also provides a wavy cut, which would have been preferred by the customer.

Second, the customer wanted information about a straight trapezoidal blade that would work for cutting aluminum foil in sachet bags. If a standard industrial razor blade would work, that was obviously the preferred solution in terms of cost and availability on the customer's part.

Sollex test lab for cutting aluminium foil

Sollex enjoys trying to help our customers with their problems and issues. We find it particularly interesting when we can visit Gemba (the customer's production environment) or use our test lab to investigate cutting challenges.

The customer sent us a large number of aluminum foil bags, which we secured to the workbench. We then tested a large number of serrated knives and several different variations of blades in different thicknesses. All blades used a 45 degree cutting angle and constant force. With straight sharpened blades, we started with cutting along the edge. The aluminum foil had to be secured and taut, otherwise nothing would work. The material was secured with clamps that held the foil tight.

Results of a study on which razor blades are best for cutting aluminum foil

The conclusions after our lab on cutting welded and reinforced double aluminum foil are as follows:

- Serrated blades don't work very well. Sollex tested 20 different serrated blades that do not cut, but only leave a mark on the foil.

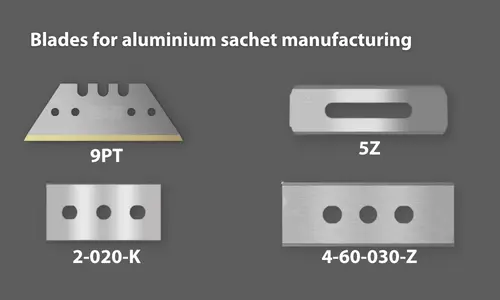

- The straight blades worked very well for cutting packages. We noted that the thinnest one that was mounted on the handle worked best. The trapezoidal blade of the 9PT knife worked very well. Sollex recommends using the 5Z or 4-60-030-Z blades because they are made of stainless steel. Stainless steel is an advantage when cutting materials with content to avoid rust.

Recommended knife blades or industrial razor blades for cutting aluminum foil:

Hassia packaging machines for flexible packaging materials

There is a German machine manufacturer called HASSIA-REDATRON (www.hassia-redatron.de) that designs and manufactures vertical packaging machines for flexible packaging materials for use in the food, cosmetics, household, personal care, pharmaceutical, chemical and other industries.

This is where the customer's input about cutting aluminium foil with serrated knives comes from. The Hassia machine has two different sachet paths which are differentiated by the two different cut specifications with tooth pitches of 1mm and 2mm respectively. The advantage of using a serrated machine knife is that you get many entry points and can cut straight into the material with a 90-degree angle of attack. Thus, a shorter stroke is required compared to a straight ground blade.

Sollex tests have shown that in the beginning it is preferable to cut aluminum foil, such as sachet bags, with a thinner razor blade. But as you increase the force, you should be able to press the serrated knife into the foil.

![8 Types of Utility Blades [GUIDE] 8 typer av knivblad för universalknivar [GUIDE] - Sollex blogg](https://cdn.starwebserver.se/shops/sollex-se/files/cache/8-types-of-utility-blades-guide-sollex-blog_medium.webp?_=1693568060)