Guide to Narrow Web Slitting: Methods, Equipment, and Tips

When it comes to narrow web slitting, several crucial aspects must be understood to ensure efficient operations and high-quality outcomes.

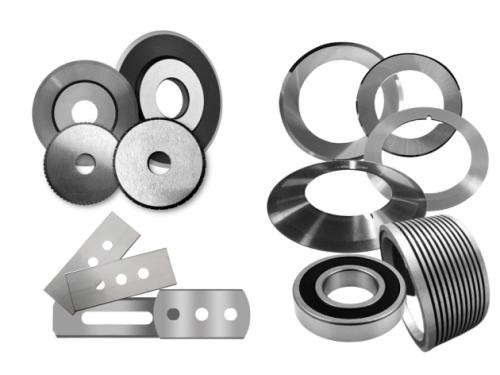

Firstly, the properties of the material being slit play a significant role. For the narrow web slitting of thin and flexible materials such as paper, labels, laminates, foil, and films, slitters capable of razor blade cutting, rotary shear knives, or crush cutting are used. Typically, materials such as various types of paper, lightweight fabrics, films, polyester, polyethylene, tape, and nonwoven materials are slit to narrow widths. Nonwoven materials are among the most challenging to slit due to the process requiring machines that eliminate roll oscillations, dust accumulation, and allow for easy adjustments.

Firstly, the properties of the material being slit play a significant role. For the narrow web slitting of thin and flexible materials such as paper, labels, laminates, foil, and films, slitters capable of razor blade cutting, rotary shear knives, or crush cutting are used. Typically, materials such as various types of paper, lightweight fabrics, films, polyester, polyethylene, tape, and nonwoven materials are slit to narrow widths. Nonwoven materials are among the most challenging to slit due to the process requiring machines that eliminate roll oscillations, dust accumulation, and allow for easy adjustments.

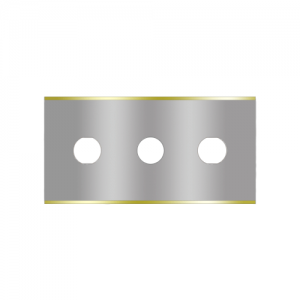

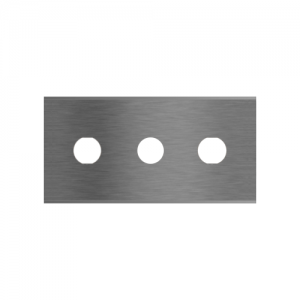

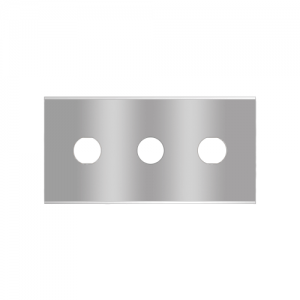

The thickness, toughness, and flexibility of the material determine the type of slitting method to be used. For example, thinner films are often best slit using industrial razor blades, which are cost-effective and produce clean cuts, while thicker or tougher materials might require shear or crush slitting techniques.

Selecting the right type of blade is another essential consideration. Razor blades are ideal for thin materials but can wear out quickly and may not handle tougher materials well. Shear blades, which function like scissors, offer precise cuts and are suitable for a range of materials. Crush slitting, which involves a rotary knife pressing against an anvil, is robust and can manage thicker materials but might result in rougher edges. Read more about these 3 slitting methods here.

The results of narrow slitting can be influenced by parameters such as the set slitting width, the material being cut, and the diameter. The slitting width on narrow webs, in turn, depends on both the material and the desired diameter.

Tension control is pivotal in the slitting process. Proper tension ensures that the material does not deform, leading to consistent and high-quality cuts. This involves maintaining consistent tension from the unwinding of the material through to the rewinding of the slit products. Advanced tension control systems are often used to achieve this consistency.

Speed and alignment are also critical factors. There are specialized narrow web slitter-rewinders designed specifically for high-speed, precise slitting and rewinding, as well as for the removal of trim and liner material. Using these in material production and conversion significantly eases the process and ensures high-quality results. The slitting speed must be optimized to prevent issues such as web tearing or bunching, and the blades must be precisely aligned to ensure clean cuts. Misaligned blades can lead to poor cut quality and increased material waste.

Speed and alignment are also critical factors. There are specialized narrow web slitter-rewinders designed specifically for high-speed, precise slitting and rewinding, as well as for the removal of trim and liner material. Using these in material production and conversion significantly eases the process and ensures high-quality results. The slitting speed must be optimized to prevent issues such as web tearing or bunching, and the blades must be precisely aligned to ensure clean cuts. Misaligned blades can lead to poor cut quality and increased material waste.

Selecting the substrate for longitudinal slitting also helps avoid the worst factors, including wrinkling, spreading, and tracking issues.

Dust and trim handling must not be overlooked. Effective dust management and trim removal systems help maintain a clean working environment and prevent contamination of the slit material.

Technological advancements have introduced features like automatic knife positioning, which reduces setup times and improves precision. Digital control systems provide real-time monitoring and adjustments, enhancing process control and product quality.

Regular maintenance of slitting equipment is vital to prevent downtime and ensure long-term efficiency. By paying attention to these factors, manufacturers can optimize their narrow web slitting processes, leading to improved efficiency, reduced waste, and higher quality end products.

___

Sollex is a Swedish supplier of industrial knives and machine blades! We have cutting products with cutting-edge technology and performance that improve manufacturing and converting processes and solve problems. With the right knives and blades you can get simplified maintenance, time savings and an improved end product.

You are welcome to contact us with your questions:

Company name: Sollex AB

Customer service and orders: order@sollex.se

Telephone: +4635–15 75 00

Address: Box 5161, 200 71, Malmö, Sweden