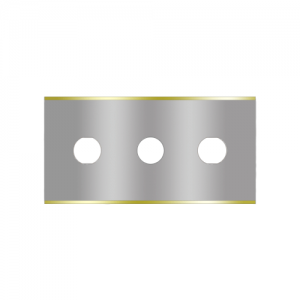

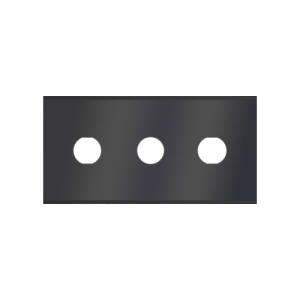

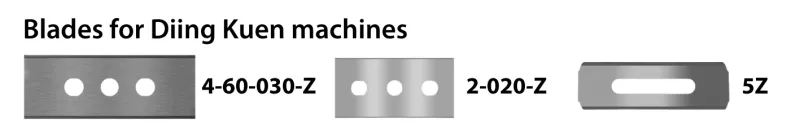

Blades for Diing Kuen Extrusion Film Machines

Razor blades for extrusion film machines

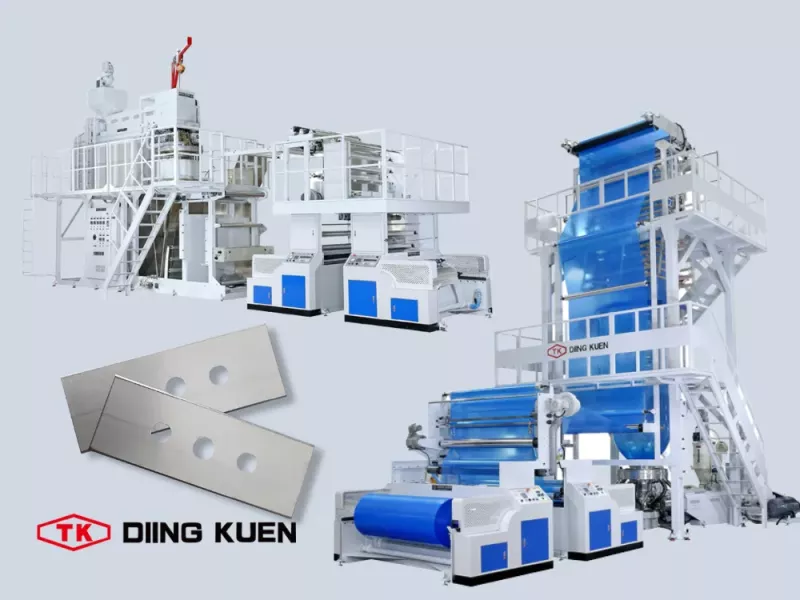

ISO9001 certified Diing Kuen Plastic Machinery Co., Ltd. was founded in 1981 in Taiwan. The company makes extruders for plastic bags, PP flat yarn, PP fibrillated yarn, Nylon filament, PP & PE mono-filament, PE &EVA net bag etc.

Diing Kuen has installed extrusion machines in more than 80 countries. It has a wide product range with: Multi layer inflation machine PP, PE, HDPE, LDPE, and LLDPE inflation machines, P.P. Flat Yarn Making Machine, P.P. Fibrillated Yarn Making Machine, Nylon Monofilament Making Machine, Plastic Extruders, Co-extrusion Machines, Plastic Monofilament Making Machines, PP/PE Woven Bag Circular Looms, Inflation Tubular Film Making Machines, Flat Yarn Making Machines, PVC Heat Shrinkable Film Making Machines, Plastic Recycling & Pelletizing Machines, Recycling & Reproducing Equipment.

Blades for extrusion blown film machines made by Diing Kuen in Taiwan

Sollex develops, manufactures and ships high performance razor blades for for extrusion film machines. Sollex razor blades give the plastic film producer performance an endurance for a professional cut and a perfect finished product.

Sollex develops, manufactures and ships high performance razor blades for for extrusion film machines. Sollex razor blades give the plastic film producer performance an endurance for a professional cut and a perfect finished product.

This text is about extruding machine manufacturers from Taiwan. Especially Diing Kuen. Others are Lung Meng and Matila industrial co. All three manufacturers of plastic converting equipment for extrusion, recycling, and printing.

These there Taiwanese machine builders have an extensive range of extrusion film machines covering the most common materials such as: HDPE, LDPE, LLDPE, PP, PE, and PA. Sollex have several different blades in different design and in different materials suitable for slitting HDPE, LDPE, LLDPE, PP, PE, and PA in machines from Lung Meng, Diing Kuen, and Matila. Diing Kuen has a broad range of machines for most materials. Below is an overview of machine types, machines, materials, thicknesses, and recommended blades.

Blown film Machines and Plastic Inflation Machines for LDPE, LLDPE Stretch Film by Diing Kuen

Diing Kuen's multilayer blown film machines are divided into four types: horizontal top rotary (HTRL), vertical top rotary (EPLR), solid (BFL) and other functional models that can heat and melt plastic particles before blowing them into thin and lightweight packaging films. To meet different packaging requirements, the film can be stacked into 3, 5 or even 7 layers. Diing Kuen can create different functional films with many different applications by using different materials to block water and oxygen or increase the freezing effect and by adjusting the thickness ratio of each layer.

Diing Kuen can meet the requirements of different types of manufacturers by designing and adapting the blown film machine according to the customer's product purpose and production capacity requirements. The film width ranges from 550 mm to 3800 mm. This allows manufacturers to insert different raw materials and at the same time adjust the film width on different rolls.

Monolayer Blown Film and Stretch Film Inflation Machines | ||||

Diing Kuen Monolayer blown film machine TK-EB-HDPE/LDPE/LLDPE high speed inflation machine | TK-EB45-1, TK-EB55-1, TK-EB65-1, TK-EB80-1 | Extrusion output: 60 to 200kg/hr Thickness of film:0.008~0.15 m/m | ||

Diing Kuen TK-EMM Monolayer blown film machine | TK-EMM45 | Extrusion output: 45kg/hr Thickness of film:0.008~0.15 m/m | ||

Diing Kuen TK-PBA - PP Blown film machine | TK-PBA-45, TK-PBA-55, TK-PBA-65, TK-PBA-80 | Extrusion output: 40 to 105 kg/h | ||

Diing Kuen TK-HTRL-Stretch film inflation machine - Mono layer | TK-HTRL 500, TK-HTRL 700, TK-HTRL 900, TK-HTRL 1100, TK-HTRL 1500, TK-HTRL 1700, TK-HTRL 2000, TK-HTRL 2500, TK-HTRL 3000 | Extrusion output: 125 to 550 kg/h | ||

Diing Kuen TK-EBLR-Multi layer Stretch film inflation machine - Mono layer | TK-EBHR 700, TK-EBHR 900, TK-EBHR 1100, TK-EBHR 1500, TK-EBHR 1700, TK-EBHR 2000, TK-EBHR 2500, TK-EBHR 3000 | Extrusion output: 125 to 375 kg/h | ||

Diing Kuen TK-EBLR-Stretch film inflation machine - Mono layer | TK-EBLR 500, TK-EBLR 700, TK-EBLR 900, TK-EBLR 1100, TK-EBLR 1500, TK-EBLR 1700, TK-EBLR 2000, TK-EBLR 2500, TK-EBLR 3000 | Extrusion output: 125 to 375 kg/h | ||

Diing Kuen TK-BFL-Multi layer inflations machine - Mono layer | TK-BFL 500, TK-BFL 700, TK-BFL 900, TK-BFL 1100, TK-BFL 1500, TK-BFL 1700, TK-BFL 2000, TK-BFL 2500, TK-BFL 3200, TK-BFL 3700, TK-BFL 4200 | Extrusion output: 125 to 480kg/hr | ||

Diing Kuen Multi layer inflation machine - Mono layer | TK-HTRH 500, TK-HTRH 700, TK-HTRH 900, TK-HTRH 1100, TK-HTRH 1500, TK-HTRH 1700, TK-HTRH 2000, TK-HTRH 2500, TK-HTRH 3000 | Extrusion output: 125 to 375 kg/h | ||

Multi layer Stretch film inflation machines | ||||

Two layers | Three layers | Five layers | Extrusion output | |

Diing Kuen TK-BFL-Multi layer inflation machine | TK-BFL 900-2C, TK-BFL 1100-2C, TK-BFL 1500T-2C, TK-BFL 1700-2C, TK-BFL 2000-2C, TK-BFL 2500-2C, TK-BFL 3200-2C, TK-BFL 3700-2C, TK-BFL 4200-2C | TK-BFL 900-3C, TK-BFL 1100-3C, TK-BFL 1500T-3C, TK-BFL 1700-3C, TK-BFL 2000-3C, TK-BFL 2500-3C, TK-BFL 3200-3C, TK-BFL 3700-3C, TK-BFL 4200-3C | TK-BFL 900-5C, TK-BFL 1100-5C, TK-BFL 1500T-5C, TK-BFL 1700-5C, TK-BFL 2000-5C, TK-BFL 2500-5C, TK-BFL 3200-5C, TK-BFL 3700-5C, TK-BFL 4200-5C | Two layers: extrusion output 185 to 480 kg/h Three layers: extrusion output 185 to 480 kg/h Five layers: extrusion output 185 to 480 kg/h |

Diing Kuen TK-HTRH-Multi layer inflation machine | TK-HTRH 500-2C, TK-HTRH 700-2C, TK-HTRH 900-2C, TK-HTRH 1100-2C, TK-HTRH 1500-2C, TK-HTRH 1700-2C, TK-HTRH 2000-2C, TK-HTRH 2500-2C, TK-HTRH 3000-2C | TK-HTRH 900-3C, TK-HTRH 1100-3C, TK-HTRH 1500-3C, TK-HTRH 1700-3C, TK-HTRH 2000-3C, TK-HTRH 2500-3C, TK-HTRH 3000-3C | K-HTRH 900-5C, TK-HTRH 1100-5C, TK-HTRH 1500-5C, TK-HTRH 1700-5C, TK-HTRH 2000-5C, TK-HTRH 2500-5C, TK-HTRH 3000-5C | Two layers: extrusion output 150 to 430 kg/h Three layers: extrusion output 185 to 430 kg/h Five layers: extrusion output 215 to 500 kg/h |

Diing Kuen TK-EBHR - Multi layer inflation machine | TK-EBHR 500-2C, TK-EBHR 700-2C, TK-EBHR 900-2C, TK-EBHR 1100-2C, TK-EBHR 1500-2C, TK-EBHR 1700-2C, TK-EBHR 2000-2C, TK-EBHR 2500-2C, TK-EBHR 3000-2C | TK-EBHR 500-3C, TK-EBHR 700-3C, TK-EBHR 900-3C, TK-EBHR 1100-3C, TK-EBHR 1500-3C, TK-EBHR 1700-3C, TK-EBHR 2000-3C, TK-EBHR 2500-3C, TK-EBHR 3000-3C | TK-EBHR 500-5C, TK-EBHR 700-5C, TK-EBHR 900-5C, TK-EBHR 1100-5C, TK-EBHR 1500-5C, TK-EBHR 1700-5C, TK-EBHR 2000-5C, TK-EBHR 2500-5C, TK-EBHR 3000-5C | Two layers: extrusion output 150 to 430 kg/h Three layers: extrusion output 185 to 430 kg/h Five layers: extrusion output 215 to 500 kg/h |

Diing Kuen TK-EBLR-Multi layer Stretch film inflation machine | TK-EBLR 700-2C, TK-EBLR 900-2C, TK-EBLR 1100-2C, TK-EBLR 1500-2C, TK-EBLR 1700-2C, TK-EBLR 2000-2C, TK-EBLR 2500-2C, TK-EBLR 3000-2C | TK-EBLR 900-3C, TK-EBLR 1100-3C, TK-EBLR 1500-3C, TK-EBLR 1700-3C, TK-EBLR 2000-3C, TK-EBLR 2500-3C, TK-EBLR 3000-3C | TK-EBLR 900-5C, TK-EBLR 1100-5C, TK-EBLR 1500-5C, TK-EBLR 1700-5C, TK-EBLR 2000-5C, TK-EBLR 2500-5C, TK-EBLR 3000-5C | Two layers: extrusion output 150 to 430 kg/h Three layers: extrusion output 185 to 430 kg/h Five layers: extrusion output 215 to 500 kg/h |

Diing Kuen TK-HTRL-Multi layer Stretch film inflation machine | TK-HTRL 500-2C, TK-HTRL 700-2C, TK-HTRL 900-2C, TK-HTRL 1100-2C, TK-HTRL 1500-2C, TK-HTRL 1700-2C, TK-HTRL 2000-2C, TK-HTRL 2500-2C, TK-HTRL 3000-2C | TK-HTRL 900-3C, TK-HTRL 1100-3C, TK-HTRL 1500-3C, TK-HTRL 1700-3C, TK-HTRL 2000-3C, TK-HTR 2500-3C, TK-HTRL 3000-3C | TK-HTRL 900-5C, TK-HTRL 1100-5C, TK-HTRL 1500-5C, TK-HTRL 1700-5C, TK-HTRL 2000-5C, TK-HTRL 2500-5C, TK-HTRL 3000-5C | Two layers: extrusion output 150 to 600 kg/h Three layers: extrusion output 220 to 800 kg/h Five layers: extrusion output 285 to 900 kg/h |

Diing Kuen emphasizes design to ensure precision in the forming head, the fundamental component of the multi-layer blow molding machine, which successfully sustains regularity in raw material flow and high-speed performance. It has little vibration, low noise, and exceptional self-cleaning capabilities for molds, enabling producers to swiftly alter raw materials, significantly decreasing waste and enhancing production efficiency.

The numerical simulation method created in partnership with the European team can model the flow of raw materials, pressure distribution, temperature, and velocity inside the plastic flow domain, and assess the uniformity of the blown film product's thickness.

Sollex Razor Blades for High-Speed Blown Film Machines

Firstly, try Sollex Zero Friction -Z ( e.g. 5z ) industrial razor blades for slitting stretch thin films without additives.

For film with additives, such as white pigments, calcium carbonate, try -K blades (e.g. 5K). A basic TiN coated razor blade -T (e.g. 5T) can be used in a wide selection of applications.

Polypropylene with additives, such as calcium carbonate which imparts rubber-like properties, is very abrasive to the blade. Cutting such plastic films takes exceptional performance and resilience. Sollex V quality, such as 5V, is able of functioning in extreme cut scenarios. Standard polypropylene devoid of additives is compatible with Sollex K and Z blades. Ceramic razor blades maintain their sharpness for an extended duration due to their self-grinding mechanism. However, the C quality is quite fragile. Sollex X (e.g. 5X) quality is effective when a solution between V and K is required.

Read our guide about product qualities & coatings here

In general: it all comes down to the blade cutting the film. If the blade can't handle your type of material, it doesn't matter how advanced your extrusion machine is.

Contact Sollex and we'll be happy to help you with samples so you can test them on your production line.

Sollex - Supplier of Industrial Razor Blades and Machine Knives

Our industrial-type razor blades are made of high quality stainless steel with different coatings on the edge or side of the blades. Sollex blades are available in solid tungsten carbide or ceramics. If you do not find the razor blade you are looking for, Sollex are able to manufacture industrial razor blades according to your drawing.

Feel free to contact us at +4635-15 75-00 or at info@sollex.se if you have any questions regarding our industrial razor blades.

KEYWORDS: Extruder, Extrusion, Extrusion line, diing kuen, Blades for Diing Kuen, Blown Film, PE, PP, HDPE, LDPE, LLDPE, EVA, Stretch, Multi layer, Mono-layer, PP blown film, Packaging