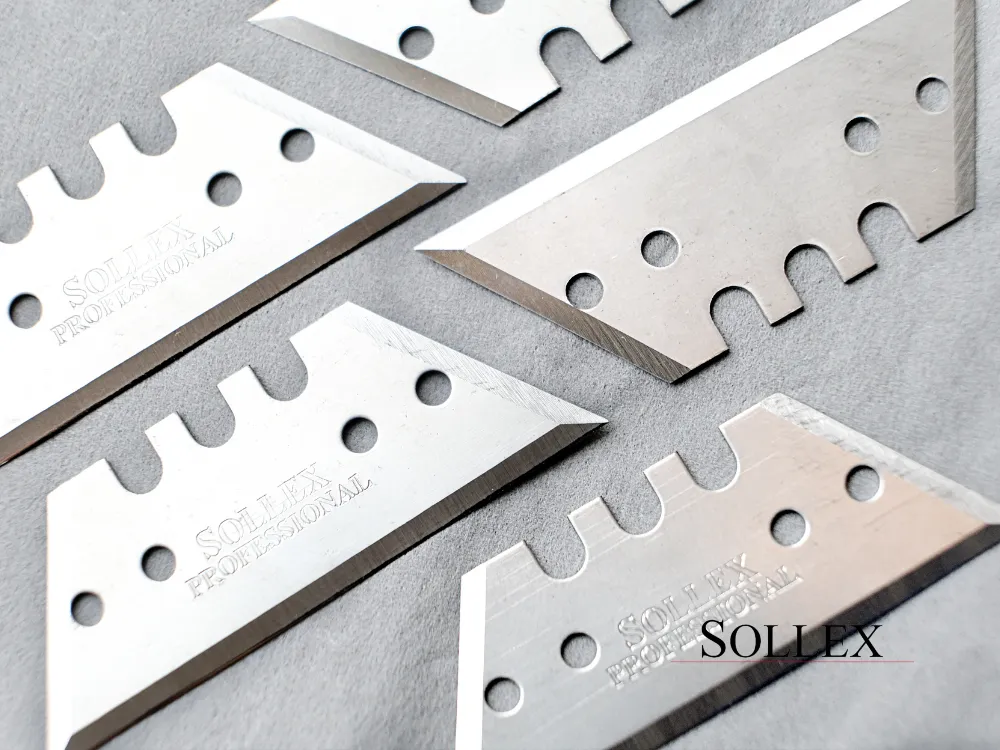

High-Performance 3-Sided Cutting Trapezoid Blade

Learn about unique Sollex trapezoid blades752.42 and 752V with 3 cutting edges

Sollex 752.42 and 752V triple edge trapezoidal blades are high performance cutting machine blades developed for a variety of applications and cutting processes, making them in great demand, particularly in industries such as plastics, packaging, textile, and aerospace. These blades are used for advanced materials such as leather, prepreg, and carbon fiber.

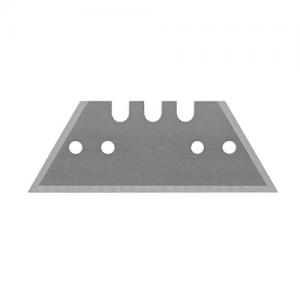

The Sollex 752 trapezoidal blade features a unique design with three sharp cutting edges. Unlike standard trapezoidal blades, which have just one long cutting edge, the 752.42 blade adds extra sharp edges on both short sides.

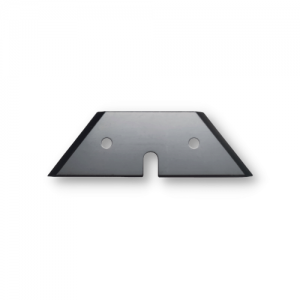

By the way, Sollex offers another trapezoidal blade with a unique design with 2 cutting sides sharpened on short sides, which is widely used in a packaging industry. You can read more about the 950V machine blade in the article here.

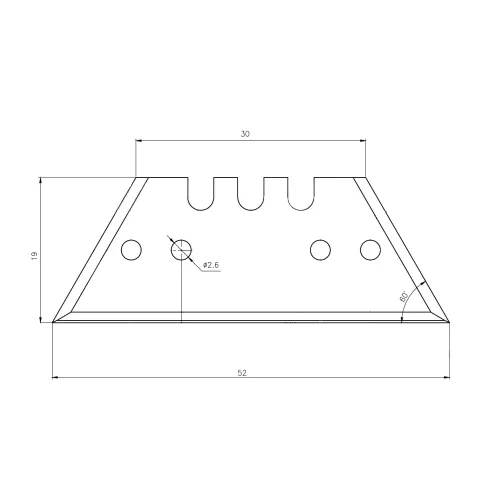

Specifications of Sollex trapezoid blade with 3 cutting edges

Measurements of the 752.42 machine blade are 52x30x19x0.65 mm. Its long cutting side is 52 mm, its shorter parallel side is 30 mm, it has two short cutting sides that are 19 mm long, and its thickness is 0.65 mm. The upper side has three jacks and four 2.6mm diameter holes that may all be utilized for secure installation in a cutting machine. The three-edged trapezoidal machine knife offers several application choices and may be placed in a cutting machine in a variety of ways. The trapezoid blade is also two-sided.

- Sollex Article Numbers: 752.42 (Carbon Steel), 752V (Solid Tungsten Carbide)

- Dimensions: 52x19x0.65 mm

- Equivalent to: Mozart 940.064, Martor Trapezklinge 752

- Material: Carbon steel or solid tungsten carbide

- Edge Grinding: Double bevel

Carbon steel and solid tungsten carbide trapezoid blades

Sollex offers the blade in two high-quality materials:

- carbon steel (art. nr. 752.42)

- solid tungsten carbide ( art. nr. 752V )

Both types have exceptional durability and cutting efficacy. Nevertheless, 752V three-sided trapezoidal blades exhibit greater durability and an extended shelf life due to the rust-resistant properties of tungsten carbide.

Application of Sollex 3-sided machine blade 752

In addition to standard cutting methods, the 752.42 blade may be used for a number of cutting techniques, such as:

In addition to standard cutting methods, the 752.42 blade may be used for a number of cutting techniques, such as:

- Horizontal cutting

- Angled mounting

- For piercing or punching materials

- V-Cut and V-groove cutting etc.

The Sollex 752 blade is essential in high-performance production. It excels in precision cutting prepregs, unidirectional tapes, and thermoplastic laminates. Composite material processing industries including aerospace, motorsports, and others benefit from its dependability. This blade is effective in cutting several materials, including:

- Films of plastic

- Laminated and coated materials

- Adhesives

- Nonwovens and textiles

- Thermoplastic laminates with fibers

- Prepreg material, carbon, aramid, and glass fibers

- Thermal plastic consolidated laminates and many others.

752.42 and 752V trapezoid blades are particularly suited for integration into advanced industrial cutting machines. Its compatibility with slitter rewinders makes it ideal for converting large rolls of materials such as plastic films, laminated composites, and textiles into smaller, precision-cut rolls. In die-cutting machines, the blade excels in shaping complex patterns and punching intricate designs in prepeg materials, carbon prepeg, adhesive layers, and fiber-reinforced thermoplastics. Furthermore, its adaptability to V-grooving and CNC routing systems facilitates the creation of precise grooves and angled cuts. Trapezoid blades are used in flatbed cutting systems, where precision in processing large sheets of materials is essential, particularly in industries such as packaging, textiles, and graphic displays. Its integration into robotic and automated cutting systems further underscores its value in modern manufacturing.

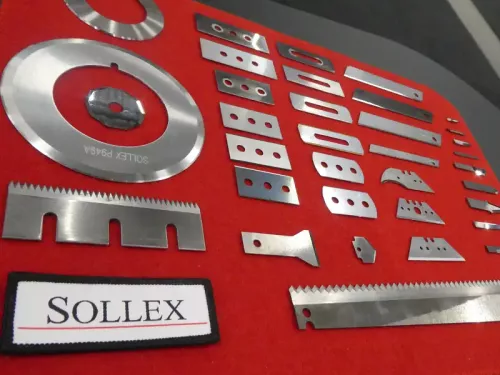

Order Machine Knives & Industrial Blades from Sollex

For over 97 years, Sollex has been manufacturing and providing cutting tools in Sweden and internationally, successfully helping clients overcome different cutting challenges by selecting right knives and blades.

For over 97 years, Sollex has been manufacturing and providing cutting tools in Sweden and internationally, successfully helping clients overcome different cutting challenges by selecting right knives and blades.

Sollex supplies the widest range of premium rewind slitting knives in the form of coated slotted razor blades, razor blades with 3 holes, injector blades, crush-cut knives, perforating knives, top and bottom shear slitting knives, but can also manufacture converting circular knives for your slitter machine.

Email us at order@sollex.se with detailed information about which machine knife or industrial razor blade you need, and we will give you the best offer.