Zund Digital Cutting Systems Overview

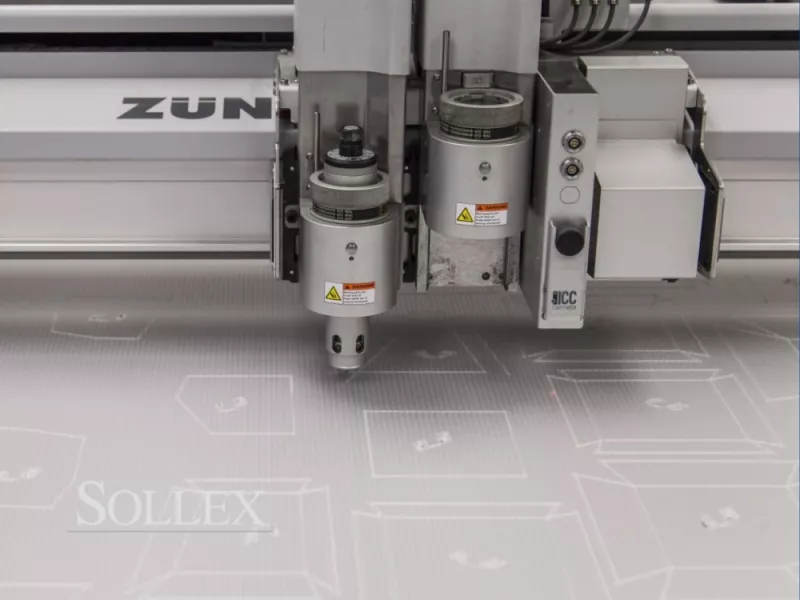

Zund Cutter - Application - Zund Cutting Systems Overview - Tools & Blades for Zund digital cutting systems

Swiss company Zünd is one of the world leading producers of multifunctional digital cutting systems, which gained a great popularity in the printing and packaging industry, as well as in graphic arts, light industry and other industrial markets, where there is a need to cut foam, cardboard, textiles, leather, composites and other materials.

Content:

- What is a Zund cutter?

- Applications

- Zund cutter specifications

- Overview of Zund cutting systems

- Overview of Zund cutting modules

- Tools and blades for Zund digital cutting systems

- Zund blade types

What is a Zund Cutter?

Zund Cutter is a modular digital cutting system that allows you to flexibly and easily cut various materials according to your specific production requirements and tasks. Zund Cutter is often used to cut materials that cannot be cut with a laser cutter, such as plastics, synthetic fabrics or foam rubber, flammable materials such as foam board and cardboard. Today, Zund offers four series of cutters: G3, S3, D3, L3. All plotter models are constantly being improved, which makes them a good long-term investment and attractive to potential buyers.

Applications of Zund Cutter

Because the Zund cutting systems are modular, it makes it possible to cut and process many different materials. A list of just a few of the materials suitable for use on the Zund is as follows:

Aramid fiber | Leather | Sandwich board | Corrugated Plastic |

Cardboard/ Corrugated cardboard / Folding carton | Fabrics/ Polyester fabric / Non woven fabrics | Films | Felt |

Tarpaulin | Paper | Glass fiber | Canvas |

Foam Board/ Foam / Hardfoam | Plywood | PVC banner / PVC | Polycarbonate / Polypropylene |

Vinyls / Reflective vinyls / Self-adhesive vynils | Styrene | Soft Metals | Rubber |

The Zund Cutter can also be used for cutting more unusual materials such as magnetic foil, metal composites or metal mesh.

Zund Cutter multifunctional features

Cutting

Cutting of flat materials of different thicknesses is carried out with suitable cutters and appropriate modules, tools and knives

V-Cutting

The V-cutting tool is used to produce angled cuts, edges or grooves to produce a range of precise angles - bevel, chamfer, groove or face cut. Various blades are suitable for different materials and can vary in size and shape. It is essential to use the correct blade for the material you want to cut, otherwise it can damage the tool and the module.

Roll stock cutting

The G3 Zund digital cutting system is equipped with a roll cutting function that allows a theoretically infinite cut size in the y-axis.

Printing

Zund prints on all possible fabrics, papers currently used for 2D printing. The integration of printing and cutting into a stacked workflow must include registration points to synchronize the printed artwork with the vector cutting file.

Print point detection

Built-in cameras allow you to identify registration dots on printed materials to synchronize printed physical content with digital vector files for cutting. The registration dots should be 1/4 inch wide, solid black, at least 5 per sheet, and arranged asymmetrically. These dots automatically synchronize the digital file with the physical file, providing the right alignment.

Edge detection

Built-in cameras enable edge detection of sheet material edges to align digital cutting file jobs to the orientation and edges of the physical material

Zund Cutting Systems Overview

Q-Line Zund Cutter Specifications

The latest generation of cutting systems, the Zünd Q-Line Cutter Line BHS180, was introduced in 2023 for completely automated material transfer from pallet to pallet and automated, continuous industrial digital manufacturing and finishing of displays and printed packaging. Bridge-free, cut board, sheet material may be precisely and easily stacked thanks to the off-load unit's revolutionary design.

The latest generation of cutting systems, the Zünd Q-Line Cutter Line BHS180, was introduced in 2023 for completely automated material transfer from pallet to pallet and automated, continuous industrial digital manufacturing and finishing of displays and printed packaging. Bridge-free, cut board, sheet material may be precisely and easily stacked thanks to the off-load unit's revolutionary design.

The new Q-Line cutters with BHS180 are available in three different sizes: Q 18-32 D - 1800x3200mm, Q 22-32 D - 2270x3200mm, Q 32-32 D - 3210x3200mm.

Q-Line’s new AUTOMO modules are compatible with any new generation tool: UNITO, DRAWTO, ELOSTO, CRETO, PERTO. Additionally, Q-Line cutters new tool modules are capable of exerting a creasing pressure of up to 500 N.

The cutting speed has increased from the previous models to 2.8 m/s due to strong and improved design and construction.

Moreover, Q-Line Cutter is equipped with the UNDERCAM tool that captures the image, identifies any distortions in the print, and ensures the cut and print are perfectly matched.

Cutting speed: 2.8 m/s

Acceleration: up to 2.1g

Creasing pressure: up to 500 N

Modules for the Q-Line Zund Digital Cutter:

- AUTOMO E ( lift speed 500 mm/s, maximum acceleration and processing speed, downward pressure of up to 20 kg )

- AUTOMO L ( for larger tools, lift speed 300 mm/s, downward pressure of up to 50 kg )

Modules are compatible with any tool from the latest generation.

Tools for the Q-Line Zund Digital Cutter:

- UNITO universal cutting tool ( for centered and off-centered drag-knife cutting )

- DRAWTO tool (to mark and draw on almost any material )

- ELOSTO 5 / 10 / 25 / 50 tool ( for cutting of materials up to 55 mm thick with oscillating blades with thicknesses of 0.63 and 1.5 mm )

- CRETO 24 / 61 / 150 / tools ( a creasing tool )

- PERTO tool ( to create perforated lines of 1.5 to 25 TPI and maximum cutting depth of 4 mm )

- VUTO tool (to make angled cuts from 0° to 60° and V-grooves)

Areas of application of Zund Q-Line Cutter: textiles, leather, rubber, Teflon, magnetic materials, solid cardboard, corrugated cardboard, honeycomb materials, display board, foam core, polypropylene PP, paper, plastic films etc.

Users of Zund Q-Line Cutter Line: box and other custom packaging manufacturers, large-scale printing, point-of-sale and point-of-purchase displays, sign manufacturers, textile and leather industries, others.

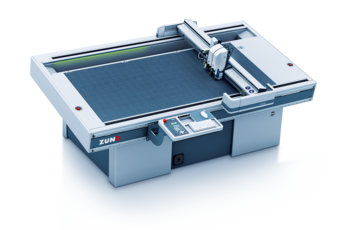

G3 Digital Cutter Specifications

The G3 cutting system can be easily adapted to the needs of your production thanks to its modular tool design and sheet/panel feeding system. You define your production tasks and requirements, and the ideal configuration of the cutting system is assembled from structural modules according to your wishes.

Modules for the G3 Digital Cutter:

Modules for the G3 Digital Cutter:

- Universal Module UM

- Router modules RM

- Punch modules PM

- Laser Module LM

- Marker modules MAM

Areas of application of Zund S3 Digital Cutter: production of POS/POP materials, stands, packaging, gift boxes, prototypes. The Zund G3 XL-3200 cutting plotter can handle most materials used in advertising production including: films, fabrics, paper, cardboard, acrylic, plastic, rubber and even some metals. Thickness of material to be processed: up to 110 mm

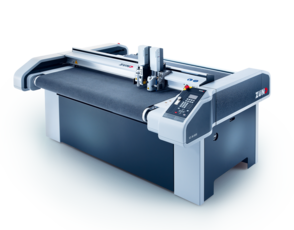

S3 Digital Cutter Specifications

The S3 cutting plotter is the most compact in the Zund digital cutting system series. The S3 handles soft, hard, dense materials up to 25 mm thick. The system is constructed with a one-piece acrylic work table, an automatic positioning system (AKI), and the ability to install up to two tools in a single job.

The S3 plotters have a tandem mode for 2 machine operators, where the work table is divided into two zones: the plotter turns off the vacuum on one side of the machine and the operator can feed or remove material, while the other side of the table is vacuum active and the cutting process is performed. This mode allows you to work without stopping the machine, which significantly increases productivity.

The S3 plotters have a tandem mode for 2 machine operators, where the work table is divided into two zones: the plotter turns off the vacuum on one side of the machine and the operator can feed or remove material, while the other side of the table is vacuum active and the cutting process is performed. This mode allows you to work without stopping the machine, which significantly increases productivity.

Cutting speed: 1.4 m/s

Modules for the S3 Digital Cutter:

- Universal Module UM-S

- Routing module RM-S

- Punch modules (2 versions).

- Notching modules

- Marker modules (6 versions)

Areas of application of Zund S3 Digital Cutter: Zund S3 cuts materials up to 25 mm thick: paper, cardboard, films, plastics, rubber, leather, fabrics, composite panels, aluminum, acrylic and many more. The thickness of the material to be processed is set by the operator in the plotter control prior to the start of the job.

Users of Zund S3 plotter: Packaging/stamping companies, print shops, manufacturers of POS, signs, displays, advertising companies, clothing companies producing textile and leather products, manufacturers of sportswear, membrane fabrics, workwear, furniture and home decor companies, automotive holdings, aviation companies and factories etc.

Zund S3 Plotter is typically used for manufacturing of cardboard packaging, POS products, promotional products, garment printing, tailoring, and production of textile advertising banners.

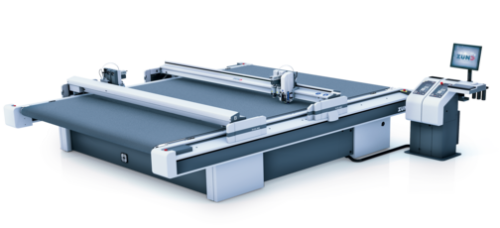

D3 Digital Cutter Specifications

The Zund D3 wide-format plotter is versatile in its application and has a wide range of tools for cutting and milling simple and complex shapes of different types of material.

A distinctive feature of this model is a system consisting of two beams. Up to three modules are installed on each beam, which doubles the speed of material processing. The automatic control system optimally distributes jobs to both beams, effectively using all six tools.

Cutting speed: 1 m/s

Modules for the D3 Digital Cutter:

Modules for the D3 Digital Cutter:

- Laser Module LM

- Marker Modules (6 versions)

- Punch Modules PM ( 3 versions)

Areas of application of Zund D3 Digital Cutter: the plotter is used for machining acrylic, plastic, cardboard, rubber, paronite, composite materials, pvc panels, foam materials, lightweight aluminum, textiles, technical fabrics, leather and other materials. Thickness of material to be processed: up to 50 mm

Users of D3 Cutter: Packaging/stamping companies, manufacturers of POS, signs, advertising companies, clothing companies producing textile and leather products, manufacturers of sportswear, membrane fabrics, workwear, furniture and home decor companies.

L3 Digital Cutter Specifications

The Zund L3 leather cutting plotter is used for cutting and punching large and small pieces of leather, roll materials, interior trim materials, soles, etc. The leather and fabric plotter cuts different types of these materials at up to 1 m/s and punches up to eight holes per second. The leather cutting plotter is equipped with a light indicator that illuminates the safe work area during cutting on the other half of the work table, so the nesting and cutting process can take place simultaneously.

Cutting speed: 1 m/s. Perforating up to eight holes per second

Modules for the L3 Digital Cutter:

- Universal Modules UM (5 versions)

- Laser Module LM

- Punch modules (3 versions)

- Marker modules (6 versions)

Areas of application of Zund L3 Digital Cutter: the L3 is used for leather goods, footwear, furniture, car upholstery, clothing, accessories and other similar applications. Thickness of material to be processed: up to 25 mm

Users of L3 Cutter: Footwear companies, textile and leather clothing companies, sportswear manufacturers, membrane fabric manufacturers, workwear manufacturers, furniture and home decor companies, automobile manufacturers, aviation companies and factories, defense industrial companies.

The plotter is equipped with an integrated tool initialization system (ITI) that automatically calibrates the tool and sets the correct cutting depth. For greater efficiency and productivity, it uses a projection system that supports the operator in all phases of production, from setting up and performing automatic or manual nesting to selecting/sorting cut parts.

The entire working surface of the plotter is divided into adjustable zones where the vacuum is applied at the point of maximum material clamping. This integrated system reduces energy costs to a minimum.

Zund Cutter Modules Overview

Zund Module |

Overview | Compatibility |

Laser Module LM | LM is suitable for cutting the following materials with high precision: paper, PVC, polyester fabric applications. | Compatible with G3 |

Marker Modules MAM | MAM is used for marking, drawing of die-lines, seams, patterns, guidelines, skinning templates etc. One or two writing and drawing tools can be installed. | Compatible with all drawing/plotting Zund Inserts |

Punch Modules PM | PM is suitable for piercing/penetrating leather, textiles, rubber or materials up to approx. 6 mm thick. Up to two tools plus a marking device or piercing needle can be installed at the same time. | Compatible with S3, L3 |

Router Modules RM | Router Modules RM is applicable for milling, engraving and polishing of different types of plastic, aluminum, wood, composites and other dense materials. Maximum milling depth is 25 mm. Uses spindle power from 1 kW. Equipped with an active cooling system for heat removal and powerful exhaust for waste removal. | Compatible with G3, D3 |

Universal Modules UM | Universal Modules UM has two versions - one for speed, the other for power. Allows you to use the maximum number of popular tools, but no more than one at a time. Provides maximum possibilities in terms of the operations to be performed at minimum cost. Each tool can be equipped with an electric drive or with a more powerful pneumatic drive. | Compatible with G3, D3 |

Kiss-cut Module KCM | Kiss-cut Module KCM has very high cutting speeds, high precision and is suitable for cutting: self-adhesive vinyls and materials with a thickness of up to 1.5 mm. | Compatible with S3 |

Tools & Blades for Zund Digital Cutting Systems

Zund offers quite a few different tools, each of which is optimally suited for a particular material: creasing tools, electric and pneumatic oscillating tools, perforating tools, driven rotary tool, universal cutting tools, routers (300W tool and 1kW router module), drawing tools and several others. Below are some of the common cutting tools, brief descriptions of them, and what blades are used with them for cutting.

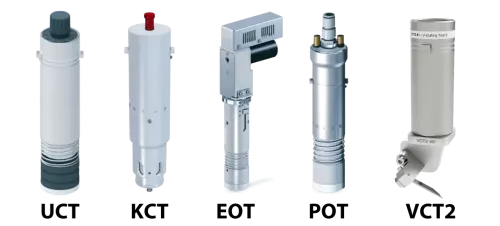

Zund Cutting Tool | Overview | Compatibility | Mountable blades |

Universal Cutting Tool | The Universal cutting tool UCT is used together with flat-stock drag knives and oscillating pointed blades to cut through a wide range of materials less than 5mm thick such as paper, vinyl, hard foam, cardboard, PVC banners, tarpaulin, coated textiles, PC, PP, plastic, film and other soft and thin materials. This tool is the most popular and used among plotters. | Compatible with G3, S3, D3, L3 | Blades to use with UCT: Z10, Z11, Z16, Z17, Z44, Z46, Z101, Z103, Z83, Z69 |

Kiss Cut Tool | The Kiss Cut Tool KCT is used in conjunction with a round-stock drag knife to hole or etch soft and thin materials up to 3mm thick such as self-adhesive vinyls, paper, plastic, masking film, fabric, fleece or harder substrates where light etching or film removal is required. A distinctive feature of the tool is that it is spring loaded. | Compatible with G3, S3, D3 | |

Electric Oscillating Tool | The Electric Oscillating Tool EOT is a tool used with flat and pointed oscillating blades for cutting through soft to medium density materials up to a thickness of 3 mm that require sawing, such as, cardboard, twin-wall sheets, honeycomb cardboard, leather, rubber, foam boards. | Compatible with G3, S3, D3, L3 | Blades to use with EOT: Z17, Z21, Z22, Z23, Z26, Z28, Z29, Z41, Z43, Z60, Z62, Z63, Z604, Z104, Z204, Z205, Z201, Z202, Z608, Z606 |

Driven Rotary Tool | The Driven Rotary Tool DRT is a rotary tool used with a drag rotary knife for cutting through soft materials such as fabrics and film, paper, thin felt, etc. | Compatible with G3, S3, D3, L3 | |

Pneumatic Oscillating Tool | The Pneumatic Oscillating Tool POT is a tool used with a long oscillating drag blade for cutting through medium to high density materials with thicknesses over 12 mm, such as honeycomb boards, rubber, felt and polycarbonates. | Compatible with G3, S3, L3, D3 | Blades to use with POT: Z16, Z17, Z21, Z22, Z23, Z26, Z28, Z29, Z41, Z43, Z61, Z62, Z63, Z64, Z68, Z104, Z204, Z205 |

Press Cutting Tool | Press Cutting Tool PCT is a tool used with a flat-stock drag knives for economical cutting of corrugated cardboard up to a thickness of 7 mm | Compatible with G3, S3, D3 | Blades to use with PCT: Z16, Z17, Z104 |

V-Cutting Tool | The V-Cutting Tool VCT is a tool used with a drag knife to cut through materials up to 16 – 25 mm thickness at different angles ( 0°, 5°, 10°, 15 °, 22.5°, 30°, 45°, 60°). Soft and medium density materials such as corrugated cardboard, honeycomb, twin-wall sheets, foam core materials, acoustic panels, polyester fiber boards can be cut with VCT | Compatible with G3, D3 |

Each tool is inserted in the appropriate module. When installing a new tool, the operator always initializes the tool by specifying the zero point and then the machine automatically calibrates it in a few seconds. All modules and tools require knives or routers to perform the cutting.

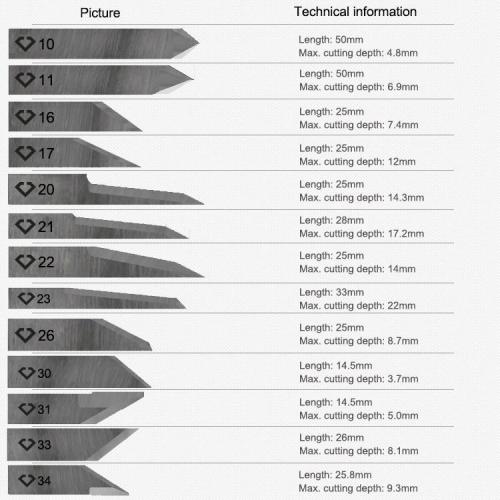

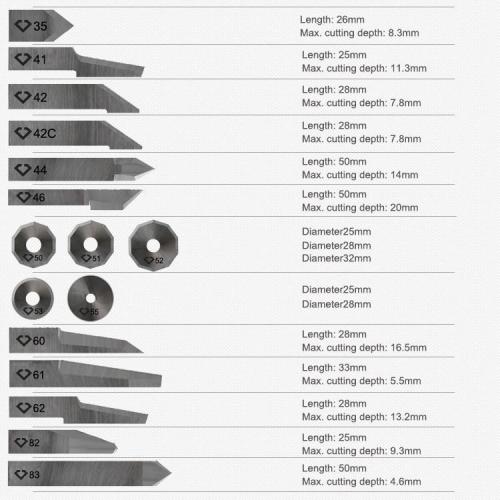

Zund Blade Types

In general, there are the following types of blades for Zund Cutters: drag blades, oscillating blades, rotary blades.

Drag blades

Drag knives are used in non-powered tools such as UCT, KCT, VCT, SCT, C2, insertion sleeve 40. Suitable for cutting foil, paper, thin folding cartons, banners, etc.

- Round-stock blades (C2, C2P, KCT, KCM-S): Z1, Z2, Z3, Z4, Z5, Z7

- Flat-stock blades (UCT, SCT, insert sleeve 40): Z6, Z10, Z11, Z44, Z46, Z101, Z102, Z103, Z83

- V-cut blades: Z70, Z71, Z701, Z73

- Mat-cutting blades (PPT): Z30, Z33, Z34, Z35

Read more about drag knives for digital cutting systems here.

Oscillating blades

Oscillating blades used in EOT/POT oscillating tools for cutting thick and tough materials.

- Oscillating blade – pointed: Z16, Z17, Z20, Z21, Z22, Z23, Z28, Z29,Z60, Z66, Z601, Z604, Z606, Z608

- Oscillating blade – flat: Z26, Z41, Z42, Z61, Z62, Z63, Z64, Z68, Z69, Z82, Z104, Z201, Z202, Z203, Z204, Z603, Z605, Z607

Read more about oscillating knives for digital cutting systems here.

Rotary blade

Rotary blades - decagonal blades - are used in DRT/PRT tools for cutting breathable materials such as textile, carbon fiber, glass fiber, etc.

Rotary blades: Z50, Z51, Z52, Z53

Order blades for Zund Cutter

You can order blades for Zund cutting system from Sollex. We stock the most common blades for Zund cutters. All of the knives we offer online are currently in use or have been tested by our customers. If you don't find what you are looking for, Sollex will design the right knife for you. If you have questions about knives for digital cutting systems, please contact Sollex at +4635-15 75 00 or by mail at order@sollex.se.

Zund Cut Center - virtual assistant

For operating the cutters, file management and selecting the right tools, Zund offers the Cut Center program, which comes as standard with all plotters. The program is loaded with all the tools that the operator has and also has a large library of materials that have ever been processed on Zund machines. This library is updated several times a year as new materials and tools are released and tested. Therefore, whatever material is loaded by the operator, the plotter will almost certainly "recognize" it and suggest the best method of processing from the database. If the tool is not available in your production facility, the machine will find the closest equivalent in stock or allow the operator to install the tool he or she deems appropriate.