Utility Knives & Blades to Cut Drywall and Roofing Felt

Recommendations on which knives and blades are suitable for drywall cutting as well as bitumen roofing felt

Here comes the best all-around knife you can find!

Content:

- Why you need a utility knife

- Utility knife to cut drywall, gypsum board, plasterboard

- Sollex recommends the best drywall knife

- Utility knife to cut torch-on felt, self-adhesive bitumen felt, shed roofing felt & underlayment

- Sollex recommends the best roofing knife

- Video review of SOLLEX 2000 knife

Why you need a utility knife

A utility knife is an essential hand cutting tool for any kind of maintenance and construction work. A utility knife typically is robust and made of metal, features a comfortable handle with a textured grip for maximum comfort and enhanced control, is equipped with a durable, sharp trapezoid blade that may be either fixed or retractable. This type of knife is considered universal and will suit every user and for almost absolutely all cutting work. By replacing different types of blades (you can read more about the types of blades in our article “8 types of utility blades”) you can expand the scope of your utility knife.

Consequently, different names are applied to utility knives, which denote either their purpose or the material they are intended to cut, such as: utility knife, box cutter, craft knife, multi-function knife, all-round knife, hobby knife, all-in-one knife, stanley knife, carpet cutter, roofing knife, dolphin knife etc. Although they are basically the same knife with different names. Yes, utility knives can differ in design, shape of the handle, the way of extending the blade, but the functionality is the same. That is, with a good and quality utility knife with excellent wear-resistant blades in your pocket, you will have a hand knife for all occasions.

Selecting the appropriate knife and spare blades for it is all that's left to do. We in turn, having more than 60 years of experience with hand knives and blades, will highlight the favorites in the knife model and blades in the opinion of our customers and advise the utility knife, which is especially fantastic to cope, in addition to the usual cutting tasks, but also with cutting a drywall material, as well as the most difficult to cut material - bitumen roofing felt.

Utility knife to cut drywall, gypsum board, plasterboard

Cutting drywall material requires 2 things: a sturdy utility knife and sharp trapezoidal utility blades. For the sake of the knife user's safety, we advise against using utility knives with snap-off blades for this kind of job. There is a huge variety of utility knives on the market and manufacturers such as Stanley, Hultafors, Bosch, Milwaukee, DeWalt, Gerber and many others. Even though it can be tough to decide, always go for a sturdy knife, ideally one made of metal, that has an easy-to-replace blade.

Blades of trapezoidal shape are designed to cut plasterboard and similar material as they are thick (usually at least 0.50mm thick), have 2 sharp tips that pierce the material and often have a deep blade grinding that makes them sharp.

Read about how to cut drywall with a utility knife in our guide here.

High quality drywall cutter blades should have the following specifications:

- blade thickness from 60mm, as the blade must retain its shape and not bend when pressure is applied or during the cutting process;

- a minimum of double bevel, as the blade must be very sharp to ensure a clean and precise cut without jagged edges;

- have multiple slots on the non-sharp side of the blade to adjust the maximum depth of blade extension and cutting;

- are made of quality carbon steel and preferably with a high chrome content;

- compliance with the dimensions and proper matching of the blade to the knife. Blades should fit standard models of knives for drywall cutting, so that there are no problems with finding the right tool;

- some blades feature a special coating (e.g., titanium like 975PT) that increases their resistance to wear and improves the quality of the cut.

Sollex recommends the best drywall utility knife

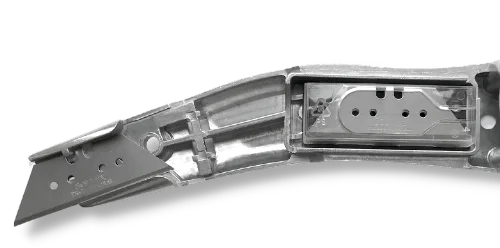

The 2000 construction knife, or “Dolphin” knife as it is also known, combined with the 975P trapezoidal blade is designed specifically for drywall cutting. The utility knife has an ergonomic handle for the best effort transfer from the hand to the material. Trapezoidal blades 975P and 975PT with titanium coating on the cutting edge have good rigidity and do not bend under pressure.

Instead of retractable blades, the utility knife 2000 features fixed blades, which guarantee a more firmly set blade that does not wobble even under extreme strain. The knife is simple to open and takes five seconds to change out the blades. An area to store a full blade dispenser is present within. When the knife is closed, the magnet in the blade holder area will align the blade and ensure that it is securely locked in place. A 310 plastic knife holster is included with the Sollex 2000 construction knife purchase so that the knife can be securely kept on a belt.

Utility knife to cut roof material & roofing felt underlayment

Roofing felt is a very abrasive and challenging-to-cut material that is used to waterproof roofs. It is composed of a mixture of bitumen modified with various components, including fiber membrane, sand, rubber, fiberglass, and reinforced polyester. When it comes to roofing, it might be challenging to find the proper knife, and particularly long-lasting knife blades.

Since roofing felt is typically delivered in rolls and must always be cut to the proper size, a roofing knife is an absolute necessity whether building a new roof or when repairing or replacing an existing one. Utility knives are also used by roof installers; however, in this case, selecting one from the available possibilities is more challenging because the roofing knife needs to meet specific requirements.

If you are on the lookout for a roofing knife, here are a few recommendations on choosing the right cutting tool:

- The roofing knife has a comfortable non-slip handle, as the roofer works while wearing thick gloves.

- The roofing knife should have as few parts as possible, especially those made of plastic. Bituminous material becomes very sticky when heated and can glue small parts together, not to mention plastic, which can melt.

- Changing the blades should not require additional tools. Roof installers often change the blades of their knives. The reason for this is that bitumen builds up on the blade and then the sharpness is lost.

- The roofing knife should ideally be quite large and preferably slightly curved.

- The roofing knife can be conveniently attached to the belt or in a sheath.

- The knife has a place to store the blade pack. Since cutting abrasive bituminous material requires sharp blades, you need access to new ones all the time.

Learn more about roofing knives and compatible blades used for roofing applications, as well as the frequently asked questions we receive from customers, here.

Sollex recommends the best roofing knife

There is no better knife for roofing work than the Sollex 2000 with the 10P hook blade. Since asphalt paper, for instance, is frequently heated by roofing professionals using a hand-held open-flame propane torch to firmly glue the joints and adhere the material to the surface, in this instance, the knife is safe to have when laying roofs because it has few parts—the body of the knife is made of metal, and the knife opening part is made of non-melting plastic.

Some years ago Sollex 2000 utility knife was awarded best in test by the leading Swedish Building. Scores of the roofing knife 2000 according to magazine "Byggnads Arbetaren" (www.byggnadsarbetaren.se):

- Weight: 186g

- Grip: 4.5 of 5,0

- Blade: 4.0 of 5,0

- Maintenance: 5.0 of 5.0

- Flexibility: 4.5 of 5.0

- General Impression: 5.0 of 5.0

As for the Sollex hook blade 10P, these blades are designed specifically for roof installers and have remained a top 5 selling product of ours for the past 10 years.

Video review of SOLLEX 2000 knife

Find below the utility knife 2000 and fantastic trapezoid blades for drywall cutting - 10P and hook blades for roofing felt - 975P.

Summary

For cutting drywall, roofing felt, insulation, and other hard materials, the 2000 utility knife is a flexible and highly recommended tool. Its fixed trapezoidal blade, sturdy metal construction, and ergonomic shape make it appropriate for a variety of cutting jobs, from general to specialized. When used in conjunction with 975P blades, the 2000 knife is particularly efficient at cutting drywall, gypsum board, and plasterboard. Because of their thickness, sharpness, and durability, these blades guarantee precise cuts that do not buckle under load.

Bitumen-based materials are typically tough to handle, yet the SOLLEX 2000 performs exceptionally well when cutting them for roofing applications. Because of its sturdy blade holder and minimal plastic components, this knife is especially well-suited for operations involving roofing. When equipped with hook blades like the 10P, it becomes an excellent tool for roofing professionals who need to make precise cuts in challenging materials. The utility knife 2000 has received top marks from Swedish Building magazine for its grip, blade quality, and overall performance. It is considered one of the best utility knives available for both drywall and roofing applications, making it a reliable choice for professionals looking for a high-quality cutting tool.