Router Bits for CNC Digital Cutter Machines

When choosing router bits for routing, milling, engraving, trimming, pattern cutting in materials like aluminum composites (ACM), wood, PVC, and acrylics, understanding the properties and best practices for each type of bit is crucial to achieving clean edges and efficient cuts. In this article we will look at such a process as CNC routing and its application in such industries as advertising, sign making, displays, logos, facades and other architectural solutions.

Content:

- About CNC router bits

- Choose the correct bit

- Types of router bits

- Applications

- Shank diameter

- Tip diameter

- Flutes

- Rotation

- Router bit detail specification

- CNC Bits for Zund, Summa

About CNC router bits

A CNC router is a computer-controlled cutting machine that uses a routing tool head and rotating milling bit to mill, shape, engrave or cut soft, medium-hard and solid materials like PVC, foam, aluminium composite ACM, wood, acrylics and solid plastics, soft metals, and other composites.

A CNC router is a computer-controlled cutting machine that uses a routing tool head and rotating milling bit to mill, shape, engrave or cut soft, medium-hard and solid materials like PVC, foam, aluminium composite ACM, wood, acrylics and solid plastics, soft metals, and other composites.

Router bits, also known as milling bits, routing bits, engraving bits, or cutting bits, are made of different durable materials (e.g. micro grain solid tungsten carbide or HSS high-speed steel), sizes, and forms and are intended for certain tasks such pattern cutting, engraving, or profiling.

CNC Routers in the Advertising, Signage and Architecture

Routing is a popular technique used today by companies involved in advertising, signage, displays, building facades, and architectural solutions because it allows the creation of complex shapes, logos, and detailed patterns on a variety of materials, particularly acrylic and aluminum composite materials, which are frequently used for sign making and architectural purposes. Aluminum composite material (ACM) is very popular actually. There are many leading brands of ACM like Dibond, Alfrex, Alupanel, Alucobond, Alpolic, AluPOLY, Dilite, Gobond, IGEPA Bond, Larson, Maxmetal, Reynobond, Vitrabond, and Pertinax.

Choosing the correct router bit is critical to attaining a clean finish: straight and V-shaped drills, for example, are utilized for a variety of cutting and engraving operations, whereas single flute drills provide the best material removal. Next, we'll go into a little more detail about the types of router bits.

Types of router bits for CNC router machines

Different milling bit types have different purposes. Not all bit types can cut every type of material, so you need to choose the right bit for your particular project. There are different types of router bits to choose from:

Different milling bit types have different purposes. Not all bit types can cut every type of material, so you need to choose the right bit for your particular project. There are different types of router bits to choose from:

- Down- and up-cut router bits

- Compression bits

- Multipurpose router bits

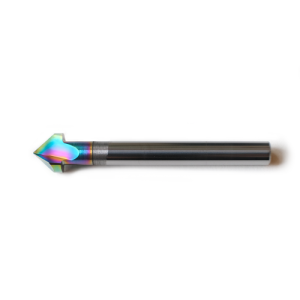

- Coated router bits

- Speciality router bits

- V-groove routing bits

- Flat-bottom milling bits

- Ball-nose milling bits

- Polishing bits and others.

Type of Router Bits | Description |

|---|---|

Down-Cut Bits | Down cut router bit pulls material away from the router and is most suited for keeping tiny items in place and routing with prints on the top side for a neater finish; however, it will not leave a clean bottom side when cutting through. |

Up-Cut Bits | Up cut router bits draw material toward the router while keeping it close to the baseplate or router table. Up cut bits are the preferred choice for deep profile cuts that need a clean bottom surface or maximal chip evacuation. |

Compression Router Bits | Compression bit is an up cut and down cut in one, which are ideal milling bits for wood. They push the upper surface of the workpiece down while pulling the lower surface of the workpiece up. |

Multipurpose Router Bits | Multipurpose router bits, that can be used on materials like wood, ACM aluminium composite of types Dibond, Forex, MDF, Pertinax, acrylic, aluminum alloy, PP corrugated plastic, expanded PVC and many others |

Coated Router Bits | Coated router bits that work great for processing a wide range of soft and hard materials, e.g. acrylic, aluminum composite, plastics PET, PP, PE, PVC-U, PS, wood, MDF, MPX, plywood etc. Offer reduced friction and heat, allowing for faster and deeper cuts. For instance, up to 4 mm thick ACM panels can be processed in a single pass at speeds of up to 150mm/s. Coated bits also last longer due to their durability. |

Speciality Router Bits | Speciality router bits for specific material, e.g. acrylic or ACP milling bits. For example, specialized CNC acrylic router bits are best suited for acrylic only, but will not be effective for aluminum composite. |

V-Groove Router Bits | V-groove routing bits are perfect for ACB and aluminum composite materials, allowing precise V-shaped grooves. |

Flat-Bottom Router Bits | Flat-bottom bits or cylindrical bits with spiral and straight-edges varieties are used in engraving and cutting functions. |

Ball-Nose Router Bits | Ball-nose or round-nose bits have a different sphere of pressure and are used for routing channels, creating flutes in solid materials, and engraving. |

Polishing Bits | Polishing bits are designed for acrylic, providing a superior finish (used only with HF routers) |

Selecting the right bit involves considering the material, the type of cut, and the required precision. For example, down-cut bits work well for detailed cuts in soft materials, while up-cut bits are better for aggressive cuts that require chip clearance. Compression bits are ideal for wood to achieve a clean edge on both sides of the cut, while coated bits are well-suited for materials that produce more heat, such as ACM and metals. The depth of the cut, speed of the router, and required detail also influence bit selection.

Different router bits for different applications

Router bits for CNC machines are widely used in the sign-making, advertising, and display industries because they allow for precise and customizable cuts on a variety of materials, including acrylic, PVC, aluminum composite panels (like Dibond, Alupanel, Gobond, Dilite, IGEPA Bond Premium, Basic IGPA, Alucobond, Reynobond, Dibond Digital, Dilite etc), wood, and various plastics. These bits make it possible to create intricate logos, text, symbols, and shapes with sharp detail, which is essential in professional signage and display production.

Router bits for CNC machines are widely used in the sign-making, advertising, and display industries because they allow for precise and customizable cuts on a variety of materials, including acrylic, PVC, aluminum composite panels (like Dibond, Alupanel, Gobond, Dilite, IGEPA Bond Premium, Basic IGPA, Alucobond, Reynobond, Dibond Digital, Dilite etc), wood, and various plastics. These bits make it possible to create intricate logos, text, symbols, and shapes with sharp detail, which is essential in professional signage and display production.

In signage, specific bits are used to achieve smooth edges and fine details on materials like acrylic or aluminum composites. V-groove bits, for instance, are excellent for creating beveled text or logos, giving the final product a dimensional, professional appearance. Down-cut bits work well for signs with printed surfaces since they push chips downwards, which helps to maintain clean edges and reduce chipping around the cut area.

For advertising displays that require backlit signs, polished-edge bits are often used on acrylic to create clear, smooth edges that allow light to pass through evenly. Compression bits are also valuable for materials like MDF or plywood that need to look clean on both sides since they reduce tear-out on the top and bottom surfaces, producing a finished look.

Display-making benefits from the flexibility of CNC router bits, as they allow for the creation of complex shapes, slots, and holes needed for custom display setups. The accuracy of CNC routing also ensures repeatability, so large quantities of identical display components can be produced quickly and consistently.

Specification of router bits for CNC routing in ACM, wood, PVC, acrylics

In CNC routing, each technical characteristic of a router bit affects how it performs in different applications. Here’s an overview of the key specifications to consider when selecting a router bit:

In CNC routing, each technical characteristic of a router bit affects how it performs in different applications. Here’s an overview of the key specifications to consider when selecting a router bit:

Shank Diameter

The shank diameter is the part of the bit that fits into the router’s collet. Common shank diameters include 6mm, 8mm, and 12mm in metric systems, or ¼ inch, ½ inch, and ¾ inch in imperial measurements. A larger shank diameter generally provides more stability and reduces vibration, which is essential for accurate cuts, especially in tougher materials.

Tip Diameter

This refers to the diameter of the cutting edge at the tip of the router bit. The tip diameter affects the width of the cut, so larger diameters are typically used for faster material removal, while smaller diameters are preferred for detailed work.

Total Length and Length of Cut

The total length of the bit includes both the shank and the cutting portion. The length of cut, however, refers specifically to the length of the cutting edge. Bits with a longer length of cut allow deeper passes but may introduce more vibration, especially in thinner materials. Choosing the right length of cut is important for controlling depth and ensuring stability; the bit should be long enough to match the material thickness but not so long as to introduce unnecessary flex.

Number of Flutes

Flutes are the grooves along the cutting edge that help clear material (or chips) from the cutting area. Flutes can be either straight or spiral cut. Most router bits have between one and four flutes. Fewer flutes allow faster chip clearance and are suitable for softer materials, while bits with more flutes provide a finer finish though it reduces the capacity for chip load, and these are ideal for hard or brittle materials. The flute length is the overall amount of space that the flute fills on CNC bits.

Rotation (Direction)

Router bits can be designed for clockwise (right-hand) or counterclockwise (left-hand) rotation, depending on the router and material being used. The rotation direction dictates the chip flow and is essential for achieving clean edges. Most bits are right-hand rotation, suitable for standard routers.

There are also other terms used in describing the milling processes, which are speed rate and chip load, feed rate, toolpath.

The speed rate is simply how fast the spindle spins, measured in RPM (revolutions per minute). Each bit is designed to handle a certain speed, so it’s important to get this right for smooth, efficient cutting.

Chip load is the amount of material the bit removes each time it rotates. If the chip load is too small, the bit generates more heat, which isn’t ideal, whereas a larger chip load actually helps keep things cooler by taking out more material each time.

Feed rate refers to how much distance the bit covers sideways every minute, often measured in inches or feet per minute. If the feed rate and chip load aren’t set properly together, the bit can wear out faster or even break.

Lastly, the toolpath is simply the route that the spindle follows to make each cut, and you set this path in the software when designing your project. An important thing to remember is that the toolpath has to follow the machine's axes—it can’t be programmed to move in directions that go against them.

Example of router bit detail specification

R502 for the Zund Routing Tool features a 2mm routing diameter and a 6mm shank diameter. This shallow tip indicates R502 will provide more detailed routing.

The routing depth in this case is similarly 6mm. The description of this specific routing bit also states on the product page that the router's length is 58mm and its maximum rotation speed (1/min) is 50000rpm.

Because Sollex R502 is versatile and coated, it may be used to shape a wide range of materials, including ACM aluminium composite Dibond, Alupanel, Gobond, Dilite, Forex, MDF, Pertinax, acrylic, aluminum alloy, PP corrugated plastic, expanded PVC, PE, PUR foam, hard paper, PA 6.6, PC, PE, PET, PETG, PMMA (Acryl), PP, PS, PVC-U plastic, PUR / PMI rigid foam board, wood, MDF, MPX, plywood, XPS rigid foam insulation board and others.

CNC Routing Bits for Zund and Summa Cutters

Summa and Zünd are well-known for their CNC digital cutting machines, which are employed in a wide range of industrial applications. Zund and Summa flatbed cutting machines are modular and can be equipped with routing tool heads, allowing them to function as both cutters and routers.

These CNC digital cutters use router bits with different diameters of both the tip and the shank, depending on the material to be cut and the process to be carried out. The most universal and common are bits with a shank diameter of 6mm and a tip diameter of 2, 3, 4, 5, 6mm. Summa does not offer V-groove bits, but 3.4 or 6 mm router bits with a maximum outer diameter of 11 mm from other manufacturers can be used in Summa router systems, as well as in Zund CNC router.

The Sollex range includes routing bits mainly for universal use with a diameter of 6mm and suitable for CNC cutting machines for processing materials such as aluminum composite material, e.g. Dibond, Alupanel, Alupanel. Dibond, Alupanel, Gobond, Dilite, IGEPA Bond Premium, Basic IGPA, Alucobond, Reynobond, Dibond Digital, Dilite, as well as acrylic, PVC, aluminum and soft metals, plastic, wood and much more.

Part item | Name | Description |

|---|---|---|

Router bits Ø3/Ø6 6mm 5pcs | Max. routing depth: 6mm, routing Ø3mm, shank Ø6mm, length 50mm; for acrylic, aluminium | |

Router bits Ø10/Ø6 5mm, V-shape 90° 5pcs | Max. routing depth: 5mm, routing Ø10mm, shank Ø6mm, length 60mm; for acrylic, Dibond | |

Router bits Ø2/Ø6 6mm, multipurpose 5pcs | Max. routing depth: 6mm, routing Ø2mm, shank Ø6mm, length 58mm; for soft, hard materials | |

Router bits Ø3/Ø6 11mm, multipurpose 5pcs | Max. routing depth: 11mm, routing Ø3mm, shank Ø6mm, length 58mm; for soft, hard materials | |

Router bits Ø4/Ø6 14mm, multipurpose 5pcs | Max routing depth: 14mm, routing Ø4mm, shank Ø6mm, length 58mm; for soft, hard materials | |

Router bits Ø3/Ø6 8mm 5pcs | Max. routing depth: 8mm, routing Ø3mm, shank Ø6mm, length 60mm; for aluminum composite material | |

Router bits Ø4/Ø6 8mm 5pcs | Max routing depth 8mm, routing Ø4mm, shank Ø6mm, length 60mm; for aluminum composite material | |

Router bits Ø3/Ø6 11mm, coated multipurpose 5pcs | Max. routing depth: 11mm, routing Ø3mm, shank Ø6mm; for soft, hard materials | |

Router bits Ø2/Ø6 6mm, coated multipurpose 5pcs | Max. routing depth: 6mm, routing Ø2mm, shank Ø6mm; for soft, hard materials |

Sollex milling bits are particularly durable and hard-wearing thanks to the special coating and are designed for industrial applications such as the manufacture of display and signs, exhibition stands, interior decoration, digital printing etc.

Tips: Choose the Right CNC Router Bit for Your Project

First, let's determine what kind of material you are working with? This affects both the material the CNC bits are made of and what type of milling bits are purchased. As mentioned above, there are some bits that are designed to best mill a specific material on the CNC cutter, so prefer them first.

For general routing tasks, selecting a larger bit diameter can speed up the process, while smaller diameters provide finer detail for intricate work. To minimize vibration and produce smoother finishes, the bit length should closely match the thickness of the media being routed. Standard routers perform best when the cutting depth per pass is limited to the bit’s diameter, while high-frequency (HF) routers can handle cuts up to 1.5 times the bit diameter. For the best results, media thickness should not exceed three times the bit diameter, ensuring a balanced load on the bit and extending its lifespan.

Sollex is a trusted European supplier of high-quality knives and blades for digital cutting systems. With a focus on precision and performance, Sollex offers a wide selection of blades compatible with leading cutting machines such as Zund, Atom, Aristo, Summa, ESKO, Elitron, IEcho, Roland, Jingwei, and Gerber cutters.

Whether you need tungsten carbide plotter knives for packaging, textiles, signage, or other industrial applications, Sollex provides durable and reliable cutting tools to ensure optimal performance on your digital cutter.