Kiss Cutting: All You Need to Know

Kiss cutting is one of the digital cutting methods performed with tangential knives to process adhesive-backed materials. Learn more about kiss-cutting, kiss-cutting materials, problems and challenges associated with this cutting method popular in the graphics, sticker and label industries.

What is Kiss Cut?

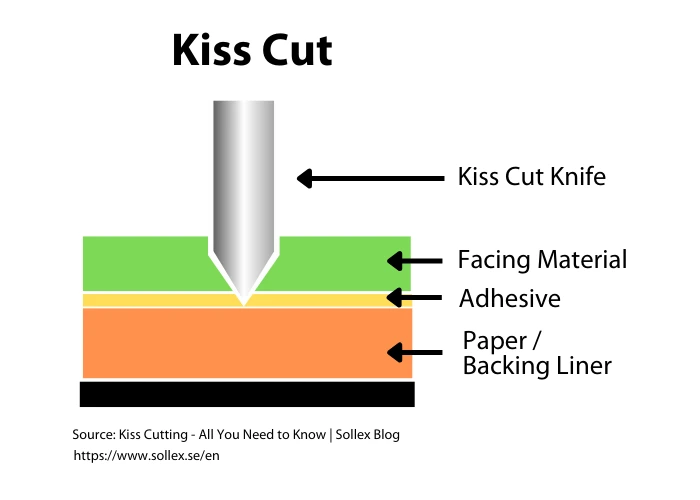

Kiss cutting is a CNC knife cutting technique used for converting and processing flexible materials with adhesive backings. Kiss cutting is a pressure-sensitive cutting method, and ensures that the kiss-cut knife cuts only the upper layer of material, leaving the backing liner intact. Why kiss cut? it is called "kiss" cutting specifically because the blade "kisses" the top layer of the material as it is cut. This allows individual parts to remain attached to the sheet until they are needed. Kiss-cut is a main cutting alternative used for vinyl and laminate cutting when creating stickers and labels, and felt to manufacture e.g. felt pads.

Kiss-Cutting Product Examples

Kiss-cutting is a type of manufacturing and converting process used to create a myriad of different adhesive-backed products.

Industry | Kiss-Cut Product Example | Description |

|---|---|---|

Stickers and Labels | Custom logo stickers | adhesive-backed stickers for branding and promotions |

Holographic labels | eye-catching labels with holographic effects for security or premium packaging | |

Signage and Graphics | Reflective safety signage | signs for roads, construction sites, or emergency situations |

Floor graphics | directional arrows or promotional messages | |

Industrial Components | Protective films for touch panels | adhesive films to protect screens from scratches and damage |

Masking films for sandblasting | custom-cut films to create intricate designs on glass or metal surfaces | |

Automotive and Aerospace | Anti-scratch protective films | films applied to car paint or surfaces to prevent scratches |

Reflective safety strips for vehicles | adhesive strips for bicycles, trucks, or helmets | |

Medical and Healthcare | Electrodes for monitoring devices | skin adhesive patches used in medical diagnostics |

Wound care dressings | adhesive dressings with precise cuts | |

Retail and Packaging | Self-adhesive coupons | coupons for promotional campaigns |

Easy-peel promotional stickers | stickers designed for quick removal and application in retail environments | |

Fashion and Textile | Heat transfer vinyl (HTV) for clothing | cut for iron-on application to t-shirts, bags, or shoes |

Reflective safety strips for garments | strips for workwear or sportswear to enhance nighttime visibility | |

Creative Products | Temporary tattoo stickers | adhesive tattoos |

DIY craft kits (e.g., scrapbooking) | pre-cut adhesive shapes for crafting and DIY projects | |

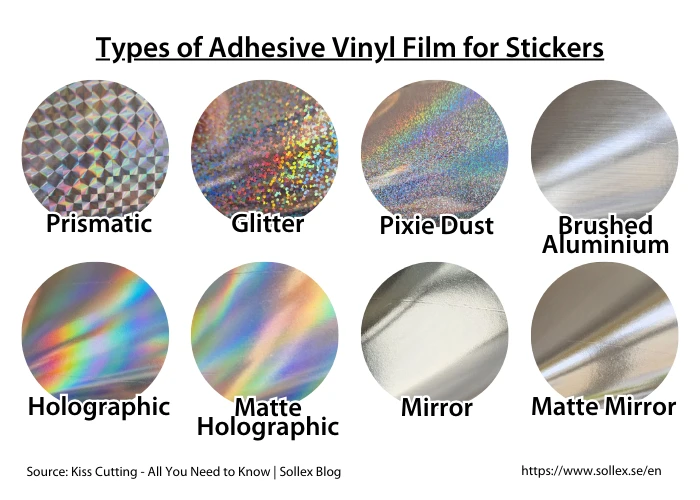

Materials for Kiss-Cutting

A wide range of flexible adhesive materials is suitable for kiss cutting. Common adhesive-backed materials include self-adhesive film, paper, carbon fiber, felt, foam and pressure-sensitive vinyl, all of which are widely used for labels, decals, stickers, gaskets and branding applications. However, vinyl is a prevalent material for kiss cutting. Decorative and signage films, such as sign vinyl, translucent film, and see-through film, are frequently kiss-cut to create customized graphics for retail and commercial use.

Specialty films such as Teflon film, membrane switch films, polyester film, PET film, and PU vinyl are often used in industries requiring precision-cut components for electronics, automotive, and medical applications. Perforated and functional films, like perforated film and see-through film, rely on kiss cutting to maintain accuracy and ease of application.

Category | Adhesive Film Type |

|---|---|

Magnetic & Adhesive Films | Magnetic film, Self-adhesive film, Self-adhesive vinyl, Pressure-sensitive vinyl |

Decorative & Signage Films | Decorative film, Sign vinyl, Translucent film, See-through film |

Reflective & Safety Films | Reflective vinyl, Emergency-vehicle reflective film, Warning film |

Protective & Masking Films | Masking film, Airbrush masking film, Sandblasting film, Scribing film |

Industrial & Specialty Films | Teflon film, Membrane switch films, Plastic film, Polyester film, PET film, PU vinyl |

Perforated & Functional Films | Perforated film, See-through film |

Several well-known brands manufacture materials suitable for kiss cutting. Among the most recognized are 3M, Avery Dennison, Orafol, and Oracal, which provide high-quality films for industrial and commercial applications.

Kiss cutting of the abovementioned flexible materials ensures high precision, clean cuts, and efficient production, making it an essential process for manufacturing stickers, labels, industrial components, and specialized films.

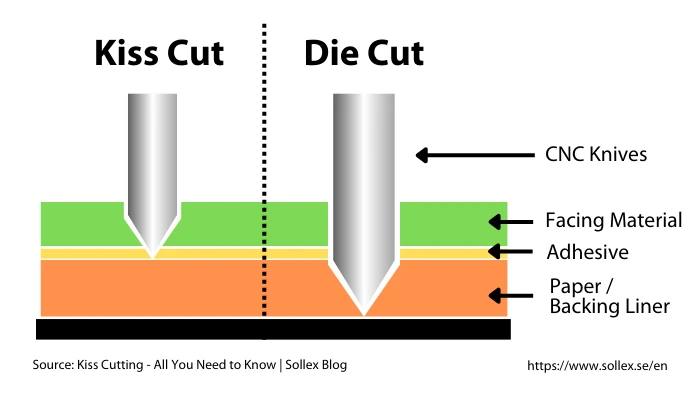

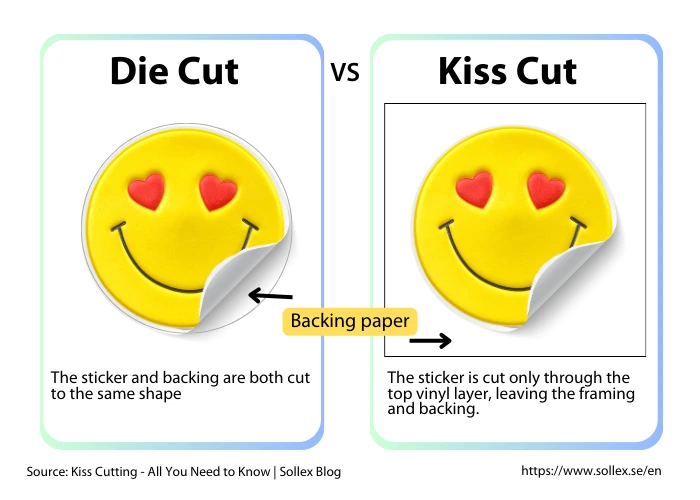

Kiss Cutting vs. Die Cutting

Kiss-cutting is a type of die-cutting, but not vice versa. Kiss-cut is performed by small tangential knives ( ex. Z1, Z2, Z3 ). The kiss-cut depth is usually adjusted up to 1 millimeter, allowing for the removal of the top layer of material while preserving a designated shape attached to the backing.

Die cutting, in contrast, by means of a die cutter press form ( steel rule die, thermal die, rotary die ) or kiss-cut knives with deeper cutting setting fully detaches individual components by cutting through all layers of the material. For example, sticker makers use both kiss cutting and die cutting to manufacture custom stickers and labels.

Kiss Cutting on Flatbed Cutting Tables

Kiss cutting is one of the CNC knife cutting methods along with oscillating, drag, rotary cutting. The kiss-cutting method is typically executed on CNC flatbed cutting tables or plotter kiss cutting machines that are equipped with a kiss-cut tool (KCT) and specialized precision tangential kiss-cut knives. KCT cutting tools precisely limit the depth of cut by means of a floating gliding shoe. This lets the tool not pass through the liner material but always cut to the exact same depth into the top layer. Control over the depth of cut comes from an ultra-fine pitch adjustment screw. This lets the operator tune in the precise depth of cut needed for the current work.

Brands of flatbed cutting tables where kiss-cutting is possible are e.g. Zund, Summa, Valiani, Esko, Kongsberg, Colex, Multicam, Jingwei JWEI etc.

Challenges and Problems When Kiss-Cutting

There are a number of problems and challenges associated with kiss cutting. Setting the correct depth of cut is critical—too shallow a depth of cut can result in material not separating properly; too deep results in a through cut and can also damage the underlying cutting mat. Depth of kiss cutting usually does not exaggerate 1 mm, which limits the areas of application. Improper matching of the kiss-cut knife and cutting material can also cause problems such as uneven cuts, rapid dulling of the knife, and consequently torn edges on the product. Product quality is also affected by cutting speed, cutting angle of the tangential knife, quality of knife sharpening, etc.

We are looking forward to hearing from you and helping you find the right high-quality knives for your application and cutting machine.

You are welcome to contact us with your questions:

Company name: Sollex AB

Customer service and orders: order@sollex.se

Telephone: +4635–15 75 00

Adress: Box 5161, 200 71, Malmö, Sweden