Industrial Cutting of Fiber Composites: Overview

Sollex provides industrial knives that are both high-quality and cost-effective for digital and ultrasonic cutting of carbon, aramid, fiberglass textiles and prepreg composites.

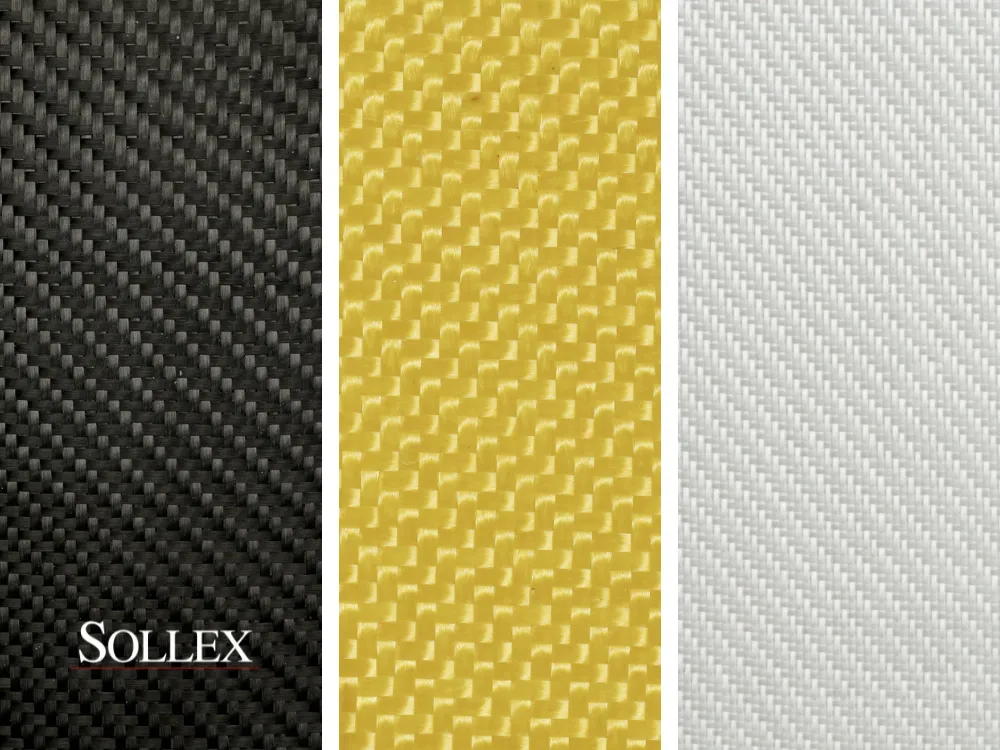

Carbon, Aramid, and Glass Fiber Composites

Composites are a cornerstone of modern manufacturing, known for their exceptional strength-to-weight ratios and durability. These materials are constructed from two key components: fibers and a matrix. The fibers, often carbon, aramid (such as Kevlar®), or glass, are responsible for the material's strength and rigidity. The matrix, typically made from either thermoset or thermoplastic resins, binds these fibers together and become prepreg composite (thermoset and thermoplastic prepregs). Composite fiber materials areideal for industries like aerospace, automotive, marine, and industrial applications.

Carbon Fiber Composites Cutting

Carbon fiber composites include dry carbon fiber fabrics and fibre-reinforced thermoplastic prepregs. Dry carbon fiber fabrics are available in woven, unidirectional (UD) and multi-axial formats. The carbon fiber composite prepreg material is pre-impregnated with resin. The carbon fiber composite cutting process must be precise to maintain the qualities of the material. Digital CNC cutting systems are widely used due to their ability to provide high precision while minimizing material waste. For thicker composite sheets, ultrasonic and waterjet cutting are reliable methods that avoid heat-affected zones, ensuring the material remains intact.

Aramid Fiber Composites Cutting

Aramid fiber composites, such as Dupont® Kevlar® aramid fibre and Twaron® are widely used in ballistic protection, aerospace, and industrial reinforcement applications. Prepreg aramid fiber composites together with woven and non-woven dry aramid fiber fabrics require specialized cutting techniques. Ultrasonic cutting is ideal for aramid fibers, as it prevents fiber pull-out while ensuring a clean edge. Laser cutting provides high precision, making it suitable for intricate designs. Additionally, rotary blade digital cutting, with specially designed industrial CNC knives, is commonly used for aramid fiber textiles.

Glass Fiber Composites Cutting

Glass fiber composites, whether they are fiberglass prepreg or dry woven, non-woven and multi-axial fiberglass fabrics, require methods that reduce fiber damage. CNC digital cutting of composite materials with rotating knives, as for carbon and aramid fibers, is often used for fiberglass, providing clean, smooth cuts with minimal fiber distortion. Waterjet cutting is also used for fiberglass cutting.

Challenges in Industrial Cutting Composites

Composite materials pose significant challenges during cutting processes. Carbon fiber composites are well-known for their impressive strength and lightweight properties; however, achieving a clean cut can be challenging due to their rigidity and propensity to fray. Aramid fibers provide outstanding impact resistance; however, they are well-known for being prone to pull fibers during cutting, potentially affecting edge quality. Glass fiber composites are economical and commonly utilized, yet their strength necessitates cutting methods that reduce harm to the fibers.

CNC Digital Cutting Knives for Composites

For cutting prepreg materials, including carbon fiber, aramid fiber, and fiberglass prepregs, CNC drag blades, decagonal and rotating knives are a popular choice.

Sollex knives such as the Z10, Z11, and Z62 are specifically designed for use with thermoset and thermoplastic matrix-based prepregs. Sollex Z10 50°, Z11 60°, and Z62 78° solid tungsten carbide drag knives are designed for use in digital cutters and flatbed cutting tables across a variety of manufacturers, including Zund, Summa, Hasler, iEcho, Esko, Kongsberg, and others.

For dry fiber materials, rotary cutting knives such as the Sollex Z50, P945, Z52, and Z53 are designed to cut composite textiles, including carbon fiber fabrics, aramid fiber fabrics (Kevlar®), and fiberglass fabrics, providing efficiency and clean edges. These solid tungsten carbide decagonal and rotary knives can be used in Atom, Bullmer, Colex, Esko, Gerber, Hasler, Humantec, iEcho, JWEI, Kongsberg, Kuris, Summa, Zund cutting machines.

Ultrasonic Knives for Composite Cutting

SOLLEX can manufacture and supply high-quality ultrasonic knives made of ultra fine grain solid tungsten carbide. The high-frequency knives designed to cut advanced composite materials such as carbon fiber, aramid, and fiberglass.

Ultrasonic knives can effectively cut, besides carbon fibre (CFRP), glass fibre / fiberglass (GFRP), aramid fibre (AFRP), a wide range of materials, including honeycomb, vulcanized and non-vulcanized rubber, food, thermoplastic foil, laminates, woven and non-woven fabrics. Ultrasonic knives used by the leading companies in automotive, aerospace, marine, medical, textiles, wind energy, military, manufacturing, sports and food processing industries.

Our ultrasonic knives are engineered to deliver precise, clean cuts with minimal heat generation, ensuring the structural integrity of the material is maintained. Contact us to learn more about ultrasonic knives and get an offer.

Sollex Cutting Tools for Composite Processing

Choosing the right cutting technology and industrial knives is critical to ensuring accuracy, efficiency and cost-effectiveness in composite material processing. Whether cutting dry fiber fabrics or prepregs, Sollex can provide your company with the right high-performance cutting tools.

Download PDF with Sollex Blades for Composites

Sollex, as a supplier for over 98 years and a leader in industrial blades, machine knives, circular slitting knives, shear cut knives, crush cut knives, pointed blades, toothed knives and custom-made solutions for industrial cutting and processing of wide range of materials, will provide you with knives and blades that guarantee the best cut and result for your specific application.

Email us at order@sollex.se for questions or to collaborate.