How to Choose the Right Safety Knife

Today companies need to invest in safe knives to ensure a safe working environment for their personnel and prevent goods from being damaged.

Safety knives are becoming more widespread and important for workplaces. Use the safety knives to ensure a safe workplace, take care of your employees and prevent injuries. In addition safe knives prevent goods from being damaged when packaging materials are cut. Today companies need to invest in safe knives and educate employees to ensure a safe working environment for their personnel.

Content:

- What is a safety knife?

- What is a safety knife blade?

- Why you should provide employees with safe knives

- Safety knives with automatic blade retraction

- Blades for safety knives with automatic blade retraction

- Safety knives with fully automatic blade retraction

- Safety knife with a concealed blade

- Safety knives with replaceable and non-replaceable concealed blades

- How to choose a safety knife depending on the material is cut

- Knives to cut cardboard

- Knives to cut layers of foil or paper

- Knives to cut plastic film, wrapping, stretch and shrink foil

- Knives to cut plastic strapping band

- Knives to cut foam and polystyrene

- Knives to cut textiles

- Why metal detectable knives are needed in the food and pharmaceutical industry

- Basic rules for the safe handling of knives in the workplace

About safety knives

A safety knife is essentially a utility knife with extra features or a modified design that lowers the possibility that the user would cut himself while using the knife. Workers in delivery and logistics departments, warehouses, and retail establishments frequently utilize these kind of knives. In addition to many other uses, safety knives and cutters are used for opening boxes and shipments, tearing shrink wrap, cutting and discarding materials, and cutting strapping material and tapes.

A safety knife is essentially a utility knife with extra features or a modified design that lowers the possibility that the user would cut himself while using the knife. Workers in delivery and logistics departments, warehouses, and retail establishments frequently utilize these kind of knives. In addition to many other uses, safety knives and cutters are used for opening boxes and shipments, tearing shrink wrap, cutting and discarding materials, and cutting strapping material and tapes.

Read more about safety knife types in our other article "6 types of safety knives".

Safety knife blades

A safety knife blade is a specially designed, sharp blade that is used in conjunction with a safety knife handle to allow for the safe manual cutting of a variety of materials. Usually, carbon steel, stainless steel, or even ceramics are used to make them. When utilized in the appropriate safety knife, safety knife blades are robust, cutting edge, and reasonably safe.

To improve user safety, these blades frequently feature a rounded tip shape or unique sharpening.

There is also the nuance that safety knives from a certain brand and model are only compatible with blades manufactured by that company. Blades for safety knives have non-standard holes for attaching in the knife or form, thus regular utility blades will not fit. Safety knife manufacturers have done this to guarantee that their cutting tools are safe to use after replacing the original blade. As a result, always pick the blade that was designed specifically for your knife.

Safety knife blades have typically rounded corners to not accidently pierce the user's hand, for example. Blades that have rounded tips are only sharp at the edge. Nearly all of the blades made by American safety knife company Slice are tipless. Moreover, replacement blades for Slice safety knives are ground and coated in a substance that minimizes skin cuts, making Slice knives exceptionally safe to use.

Safety knife blades have typically rounded corners to not accidently pierce the user's hand, for example. Blades that have rounded tips are only sharp at the edge. Nearly all of the blades made by American safety knife company Slice are tipless. Moreover, replacement blades for Slice safety knives are ground and coated in a substance that minimizes skin cuts, making Slice knives exceptionally safe to use.

Why you should provide employees with safe knives

When a worker is cutting or trimming, they frequently sustain hand knife injuries as a result of the knife sliding on them. Most of the time, the worker's other hand comes into touch with the blade, cutting the hand or fingers. Aside from the thigh, other body areas might also get injuries.

When a worker is cutting or trimming, they frequently sustain hand knife injuries as a result of the knife sliding on them. Most of the time, the worker's other hand comes into touch with the blade, cutting the hand or fingers. Aside from the thigh, other body areas might also get injuries.

UNSAFE knives are the cause of almost half of all manual tool-related workplace injuries.

We can roughly classify safety knives into 3 types:

- safety knives with automatic blade retraction

- safety knives with fully automatic blade retraction

- safety knives with concealed blades

Automatic blade retraction safety knives

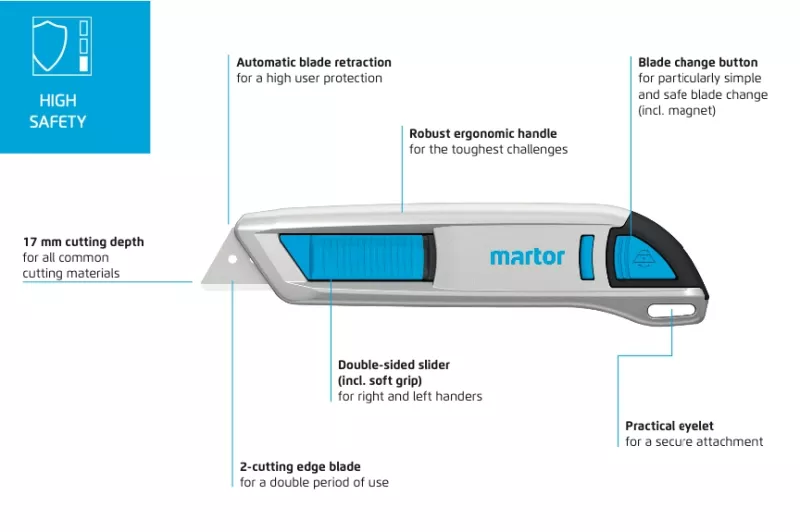

Using safety knives that have automatic blade retraction ensures that users are kept well protected. The blade vanishes into the handle the moment your thumb leaves the slider. Another benefit of these safety knives is that the blade automatically retracts, so there's no chance that you may accidently cut yourself or someone else if you leave the knife out of a drawer or on a table with its blade extended.

All Martor Secunorm safety knives are the safety knives with an automatic blade retraction.

Blades for safety knives with automatic blade retraction

Knife blades for these kinds of safety knives come in many shapes and types, each designed for a specific purpose or job.

There are different types of knife blades used with these safety knives with automatic blade retraction:

- trapezoid utility blades ( cutting depth 9 - 20mm)

- snap-off blades (cutting depth depends on the length of blade, approx. up to 70mm)

- rounded-tip hook blades (cutting depth approx. 7mm)

- industrial knife blades with 4 corners (cutting depth approx. 10mm) and others

Fully automatic blade retraction safety knives

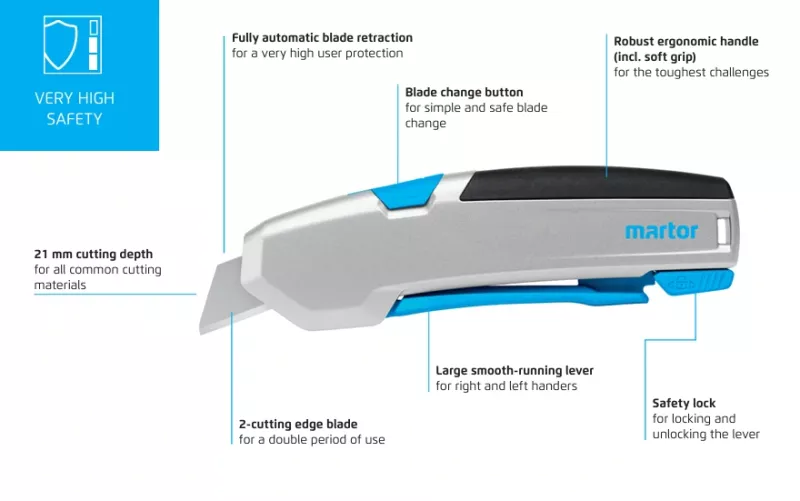

Fully automatic knives differ from the safety knives with automatic blade retraction mentioned above in that the blade retracts into the handle as soon as it exits the material to be cut, regardless of whether the user continues to pull the trigger or press the slider with their finger. This protects your workers, for instance, from potential cuts to their legs when they open a package or cut a cardboard box with a swing.

However, bear in mind that using this kind of knife may be challenging if the material you are cutting, for example, moves or vibrates, since the blade will move each time, making the cutting process more difficult.

All Martor Secupro safety knives are the safety knives with fully automatic blade retraction.

Concealed blade safety knives

Safety knives with hidden blades are widely regarded as the most secure utility knives. Their great level of safety comes from the fact that just a tiny portion of the blade is visible and available for cutting, while the rest is concealed. This design completely avoids touch between the knife blade and the user. The form of an enclosed blade safety knife mimics a hook, making it difficult for the user to be hurt while cutting or to reach the blade with the fingers. Such a blade protects not only the worker, but also the contents in boxes and containers. This ensures optimum safety against cutting while also protecting your items dependably.

Knives of this type come with replaceable concealed blades, meaning you can replace the entire head with the blade, or solid disposable knives without the ability to replace the blade, but only with the ability to replace the entire safety knife. Safety knives with concealed blades range from very simple disposable safety knives to knives with replaceable concealed blades and food safety knives that can be detected by metal detectors.

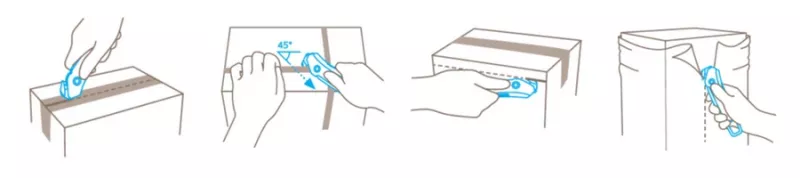

The blade shape allows easy and safe opening and cutting with a "pull" motion. The user grips the hook on the material to be cut and pulls it sideways at a 45-degree angle, downward or toward him.

Cutting depth of knives with concealed knife blades varies usually between 4-6mm.

Material to cut with safety knives with concealed blades:

Material to cut with safety knives with concealed blades:

- packaging

- >tape

- plastic strapping bands

- plastic film, wrapping, stretch and shrink foil

- safety belt

- coated and laminated film

- textiles

- cardboard max 1-ply

Sollex keeps most spare blades for Martor and Klever safety knives with concealed blade in stock. All Martor Secumax safety knives are safety knives with concealed blade and the maximum safety guarantee.

Safety knives with exchangeable and non-exchangeable concealed blades

Safety knives of this sort have interchangeable hidden blades, which means you may replace the entire head along with the blade, as opposed to solid disposable knives that cannot be replaced. However, most of these knives do not have interchangeable blades, which means that the entire knife is discarded once the blade has become worthless and dull. These knives are less expensive than knives with replaceable blades.

We recommend the following disposable safety knives with concealed blade:

- Klever Kutter

- Sollex Safety Cutter

- Martor Secumax 145, 150

We recommend the following knives with a concealed blade whose blade can be replaced:

- Klever Xchange

- Martor Secumax 320, 350, Secumax Opticut

- Mure & Peyrot Grepin 2, Jalle

How to choose a safety knife based on the material you cut

Choosing the right safety knife for the job is very important to ensure that the worker gets the job done correctly and safely. Answer the following questions to find the appropriate knife for the cutting task:

- What material will you cut?

- How deep should the cut be?

- What kind of blade is required does it fit your purpose?

To cut cardboard use the following safety knives:

- Martor Secunorm 300, 380, 500, 525, 540, Secupro 625, Secupro Martego

- Sollex Prosafe safety knife

- Slice Box Cutter 10400, 10503, Slice Manual Carton Cutter 10585, Slice Utility knife 10550

To cut layers of foil or paper use:

- Martor Secunorm 500, 525, 540, Secunorm Mizar, Secupro Martego, Maxisafe, Merak

- Sollex Prosafe safety knife

- Mure & Peyrot Craste to rip paper on spool

- Slice Industrial knife 10559, Slice Utility knife 10550, 10554, 10558

To cut plastic film, wrapping, stretch and shrink foil use:

- Martor Secunorm 500, Secunorm Mizar, Secunorm Profi40 MDP, Secupro Martego

- Sollex Prosafe safety knife

- Mure & Peyrot Bordeaux, Jalle

- Slice Box Cutter 10400, 10503

To cut plastic strapping band use:

- Martor Secunorm 300, 380, 500, 525, 540, Secunorm Mizar, Secupro Martego, Merak, Maxisafe

- Mure & Peyrot Pyla

To cut foam and polystyrene use the following safety knives:

- Martor Secunorm 380, 525, 540, Secunorm Profi40 MDP, Secumax Opticut

- Sollex Prosafe safety knife

- Slice Utility knife 10550, 10554, 10558

To cut textiles use the following safety knives:

- Martor Secunorm 500, 525, 540, Secunorm Mizar, Martego, Maxisafe, Merak

- Sollex Prosafe safety knife

- Slice Pen Cutter

Metal detectable safety knives for the food and pharmaceutical industry

Products in the food and pharmaceutical industries should not include particles of other elements accidently swallowed during the production process. A manufacturing process contamination can result in major equipment damage, product recalls, and, worst of all, consumer harm. High expenses and a possible reputational harm that should not be understated are the end results. To avoid this, manufacturers must use special equipment that detects metal. A metal scanner or X-ray machine can identify and remove a small piece of metal detectable plastic, such as that found in safety knife blades, from the finished product.

Particularly, food manufacturers require that every tool in the hygienic area be made of metal. The finished product must be able to be x-rayed to ensure that the packaging contains just food. For this reason, metal detectable safety knives are used. Metal particles are present in the knife handle of metal detectable safety knives, making it easy to identify the plastic or composite materials they are composed of

Sollex recommends the following metal detectable safety knives:

- Klever Kutter KCJ-1MD

- Martor Secumax 320 MDP, Secunorm Smartcut MDP, Secunorm Profi 25 MDP

- Mure & Peyrot Pyla

Read more on the metal detectable safety knives here.

Basic rules for the safe handling of knives in the workplace

- Changing the dull blade on time is the most important safety tip while using knives! Because the user must exert more pressure and power to cut through the material, a duller blade makes the knife less safe. Therefore, keep an eye on this and maintain a supply of new blades so that your staff members may swap out the knife's dull blade as necessary.

- Selecting the right knife for the job at hand is essential. It's possible that many knives will be utilized for various jobs on the same project. Work knives come in a variety of forms, so give your staff the ones that best suit their methods of operation.

- Ongoing inspections are necessary to ensure that safety knives are safe for use and free from visible flaws.

- It's important to clarify if the knives belonging to your staff members are personal or shared. Work knives are safer to provide employees for personal use so they always have the proper equipment for the task instead of having to search for the right tool or make a cut with the wrong tool.

- Equip employees with personal protective equipment (PPE) that guards against hazards to their health or safety while they are at work. It may consist of things like mittens, gloves, and eye protection.

- When it comes to knife safety, sufficient illumination, safety blade boxes (9810 or 988 for instance), and proper maintenance are essential.

- A serious stab wound can cause severe bleeding. Immediate first aid can save a life. At least one person in the company who is trained in first aid for stab wounds and severe bleeding must be present to provide first aid.

If you need help choosing the right safety knife or blades for your company - contact Sollex, we can help you!