Drag Knife for CNC Digital Cutters and Plotters

Everything you need to know about drag knives

Content:

- About drag knife

- Applications

- Difference between drag and tangential knives

- Cutter offset

- Zund drag knives

- ESKO / Kongsberg drag knives

- Summa drag knives

- Buy Knives for CNC Digital Cutting Systems

About Drag Knife & How It Cuts

The common cutting method for vinyl plotters or flatbed digital cutting tables is the drag knife technology. The movement of the drag knife is usually provided by a non-powered cutting module or tool, depending on the specification and manufacturer of the CNC plotter. The cutter blade is fixed in the knife mount and in some models, if the blade is mounted at an angle, it rotates around the axis of the knife holder when turning and cutting corners in a web.

The common cutting method for vinyl plotters or flatbed digital cutting tables is the drag knife technology. The movement of the drag knife is usually provided by a non-powered cutting module or tool, depending on the specification and manufacturer of the CNC plotter. The cutter blade is fixed in the knife mount and in some models, if the blade is mounted at an angle, it rotates around the axis of the knife holder when turning and cutting corners in a web.

A "drag knife" follows the tool holder trajectory as it cuts. In order to change direction smoothly, the blade is typically pivoted in the tool holder.

Drag knives move and cut through the material like a knife cuts through butter. Since the cutting motion with the drag knife technology is dragging, these knives are usually used to cut thin materials (adhesive vinyl), flexible materials (corrugated cardboard) or thicker materials but soft materials (foam board). But more typically the drag knife is used to cut self-adhesive vinyl for manufacturing stickers, stencils and labels. Cutting thicker or rigid media with drag knives may result in slight distortions or rounded corners on the material.

The drag knife has different designs depending on the CNC cutter type and its application. In addition to the design, the knives differ in such characteristics as:

- cutting depth

- shape of the knife shank: flat or rounded

- cutter offset

- pre-cut

- post-cut characteristics (in case of a knife with two cutting sides)

- material from which the knife is made

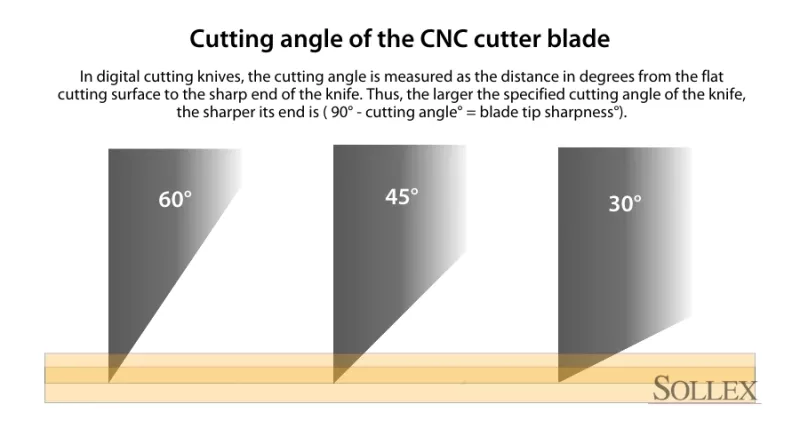

- angle of the cutting side in relation to the cutting surface: 36°, 45°, 55°, 60°

- number of sharp cutting sides: single and double-sided knives

It should be noted in turn that with drag knives, a smaller cutting angle means less drag force.

The drag digital cutting knife moves through the material without completely withdrawing from the material, even when turning to change the cutting direction. To change the cutting path, the knife is lifted slightly and turned in the desired direction and then lowered again to the desired depth to continue cutting, resembling the movement technique of a tangential knife. Therefore, sometimes on thicker and softer materials, the places where the knife changed angle and trajectory on the turn may be more noticeable. However, with tangential cutting, the knife is lifted completely out of the material, rotated and lowered into the material already with the correct position of the cutting path, which ensures the best and smoothest corners on the material being cut.

Tangential knife technology is typically found only in flatbed cutters.

Applications of Drag Knives in CNC Digital Cutting

Drag knives are usually less expensive among other CNC knife options. They are also more durable. They are suitable for cutting a wide range of materials, from thin materials such as films, vinyl, paper, fabric, to thicker materials such as carton, cardboard, RE-board, rubber mats, PVC, polypropylene. But ultimately, drag knives are best suited for thinner and more flexible materials such as vinyl, thin plastic, paper and thin cardboard.

Drag blade cutting on CNC digital cutters is often used to create labels, stickers, signage, decals, packaging and prototypes, craft and apparel.

The Difference Between Drag & Tangential Knives

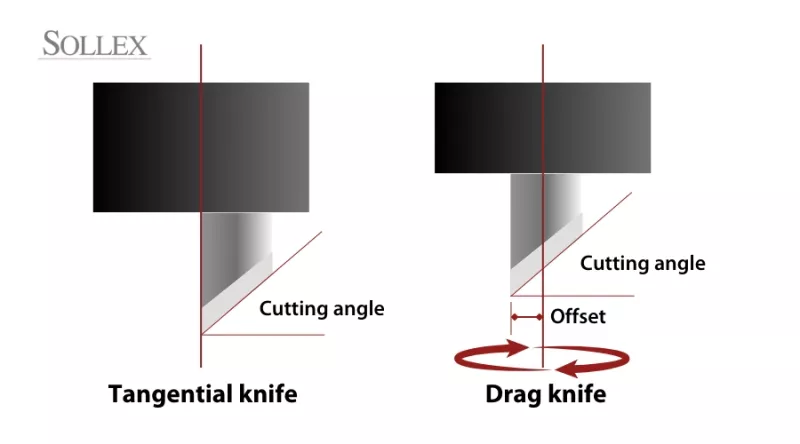

The tangential knife is driven by a motor, unlike the drag knife. This technology sets the knife at the desired angle with respect to the cutting surface and the direction of the future cutting path.

Instead of a freely rotating knife as found in drag knife cutters, a tangential knife or a kiss-cut knife is controlled by a motor. This motor positions the knife at the correct angle and place for each cut. While the drag knife remains in the media when changing directions during cutting, tangential technology lifts the knife up from the media, rotates it and lowers it back into the media. Tangential knife technology allows perfectly shaped cut corners in the thin media, but also in thick, rigid media since there are no drag forces that will influence the knife’s trajectory.

Drag knife cutting technology is preferred for production of marketing POS (point of sale), billboards, light boxes, and window graphics. Tangential knife cutting technology is preferred for manufacturing stickers, labels, floor graphics, vehicle graphics, textile, sandblast, signage, and more.

Cutter Offset for Drag Knives

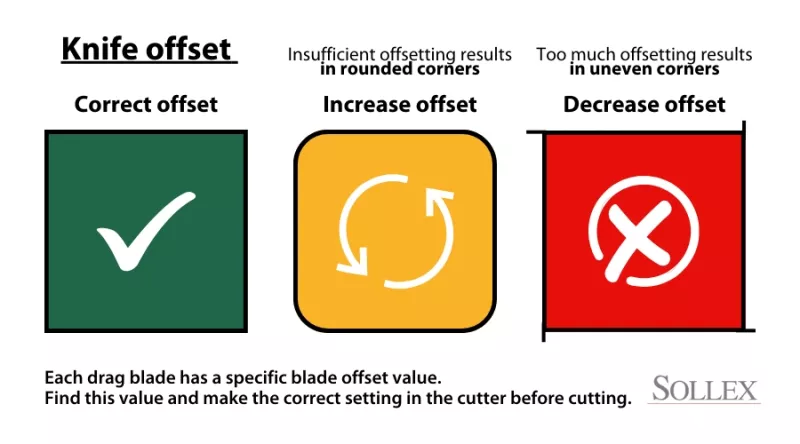

The cutter offset, or blade offset, is the distance from the point at which the blade is cutting to the point about which it is rotating - the axial center. With other words, offset is a quantity that defines the radius of rotation of the blade and compensates for distance when cornering. Correct blade offset for the drag blade is essential for good quality corners. By the way, blade offset only applies to a drag knife.

Common problems associated with the drag knife offset compensation value

- Notched corners

The offset value set on the plotter is greater than the actual offset value on the blade. The plotter goes farther out of the corner than is necessary to make the cut according to the specified layout. Jagged or ragged corners are created when the cutting line is curved.

- Rounded corners

The offset value set on the plotter is less than the required value for a given blade. The offset compensation made by the plotter is not large enough. The corners of the contour are radiused.

A blade with a larger offset handles thicker and laminated materials better. Offsets greater than 1 mm are modeled to help compensate for material properties to avoid rounded corners.

Without blade offset compensation, the drag knife will not be able to cut sharp corners because the drag knife has an off-center point to provide rotation. The drag knife cutting technique forms rounded corners. To avoid the formation of rounded corners, drag knife plotters must take into account blade offset compensation. If the blade offset is 0 - the corners are rounded. If the blade offset is too high, the corners will be beveled. To make a 90-degree cut, the cutting angle must be exceeded by the amount of blade offset and rotated by a radius equal to the offset. The offset normally ranges from 0.25 mm to 1.0 mm.

Drag Knives for Zund Digital Cutting Systems

One of the most common manufacturers in Europe of CNC digital cutting tables is Zund. Of course, they also have a drag cutting technique. Their cutting tables are modularly equipped with the necessary modules and tools for the selected cutting technique and the material to be cut. Read more about Zund cutting tables here.

As far as cutting with drag knives is concerned, this cutting technique can be performed on UCT, KCT, VCT, SCT, C2, PPT + sleeve 40 which are non-powered tools.

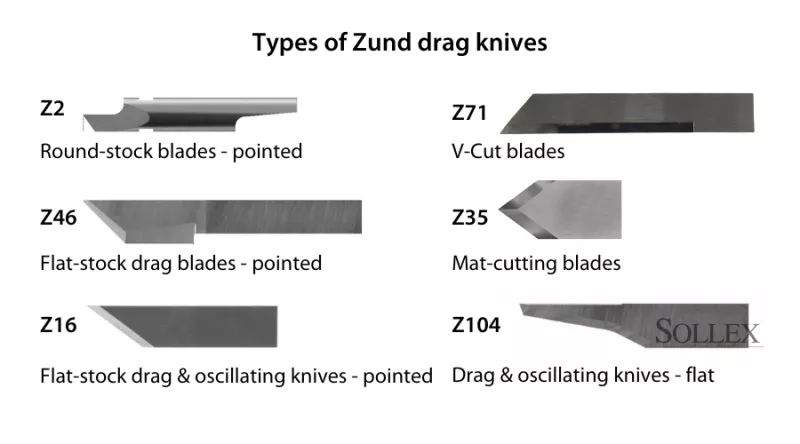

Types of Zund drag knives: Round-stock, flat-stock blade, mat-cutting blade, V-cut blade

Zund drag knives are suitable for foils, paper, thin folding carton, banners, etc.

Type of drag blade | Drag blade | Blade holder |

|---|---|---|

Round-stock blades - pointed | C2, C2P, KCT+sleeve 40, KCM-S | |

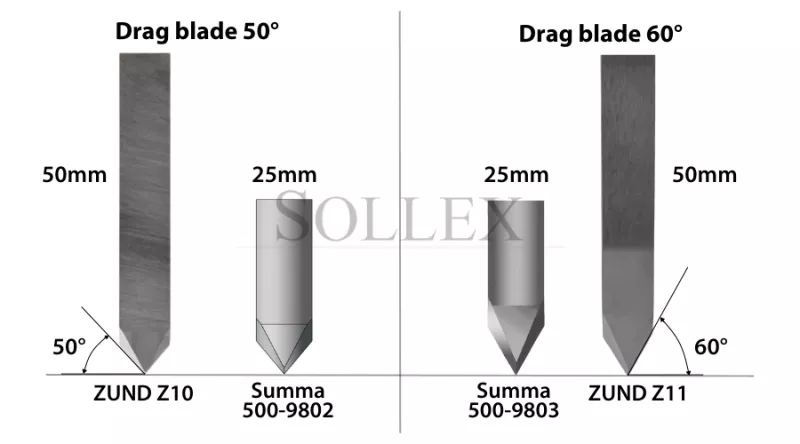

Flat-stock drag blades - pointed | Z10, Z11, Z44, Z83, Z101, Z103, : UCT + sleeve 40 / SCT + Blade holder type 1 3960322; Z46, Z102: UCT, SCT + Blade holder type 5 3960320 | |

Flat-stock drag and oscillating knives - pointed | POT+Blade holder 0.63 mm, UCT+Blade holder type 3 3960324, EOT, POT+ Blade holder 1.5 mm + Blade reduction 1.5/ 0.63 mm 5003138, EOT-205+Blade holder 5208744, SCT+Blade holder type 3 3960324, PCT + Blade holder type 3 3960324 | |

Drag and oscillating knives - flat | POT + Blade holder 0.63 mm, EOT, POT + Blade holder 1.5 mm + Blade reduction 1.5/ 0.63 mm 5003138, EOT-250 + Blade holder 5208744, PCT + Blade holder type 3 3960324 | |

V-Cut blades | Z70: T75+3102186 / 5005782 Z71: VCT+Blade holder 5206263 / 5206264 Z73: VCT+5206262, T75+3102186 Z701: VCT2+5221596 | |

Mat-cutting blades | Z30, Z31, Z33, Z34, Z35 | PPT + Blade holder 3960331 |

Drag knives for ESKO / Kongsberg CNC cutters

Drag knives for CNC cutting tables made by ESKO Kongsberg are also available. They often have the same blade design as Zund knives and some other manufacturers, and can be interchangeable, but not completely identical in some cases. But you should of course read the knife specifications before choosing a drag knife or its alternative. You can read more about the interchangeability of digital cutting knives in our blog "Zund & Summa Blades Fit Various Digital Cutting Machines".

For example, the knife from Summa 500-9807, Zund Z46 and Esko BLD-SF346 (i-346) / G42458406 are almost identical: they have the same 6mm width, thickness, length and cutting angle.

Summa 500-9803 60°, Z11 and Esko BLD-DF113 G42443036 are also similar knives, with the same 50° angle, but in this case Summa 500-9803 is twice as short and is 25mm instead of 50mm.

Download PDF | Knives for Zund & Summa F-serie Cutter Tables

Drag Knives for Summa Vinyl Cutters

As for the CNC vinyl cutters from the manufacturer Summa, they cut adhesive vinyl film, foil, adhesive PVC, banner vinyl using drag knives.

Summa drag module is required to use the drag knife cutting technique. For example, Summa S One and S2 D-Series cutters use only drag knives. Summa S2 tangential cutters may optionally use drag knives, giving up the advantages of tangential cutting. Summa Series F tables can be equipped with 2 modules and different tools, but Drag module is standard and Tangential - optional.

There are 3 types of drag knives for Summa vinyl cutters: 391-231 - Drag Knife - 60°, 391-358 - Drag Knife - 55°, 391-360 - Standard Knife 36°.,Summa cutters ship with a 36 degrees standard knife pre-installed. The knife is the best choice for cutting the vast majority of common sign vinyls. As a general rule, use the shallowest angle knife that will cut the depth required by the workflow. For example, 36 degrees is preferable to 55 degrees, and 55 degrees is preferable to 60 degrees.

Summa vinyl cutters use a knife holder assembly to stabilize and protect the knife during the cutting process. There are 2 drag knife holders for Summa drag knife roll cutters (S2 D-series and S One-Series) and one for S2 Tangential cutters.

391-360 36 Drag Blade | 391-358 55 Drag Blade | 391-231 60 Drag Blade | |

|---|---|---|---|

Max. Thickness (mm) | 0.25 | 0.80 | 0.60 |

Max. FlexCut Thickness (mm) | 0.50 | 0.80 | 0.60 |

Material to cut | Most standard sign vinyls | Sandblast ( monument) | Rhinestone, heat press (apparel) |

Below is a table with drag cutter blades for Summa vinyl cutters and which vinyl cutters they fit.

Drag Knives |

Summa Cutter Serie |

Compatible Blade Holder |

||

|---|---|---|---|---|

391-360 Summa 36° Drag Knife Blade Max thickness 0.25mm flexcut 0.50mm knife offset 0.43mm overcut 0.10mm | Summa F Series Flatbed Cutters Summa S2 Series Vinyl Cutters Summa S Class Vinyl Cutters SummaSign/SummaSign Pro D Series Vinyl Cutters SummaCut Series Vinyl Cutters Summa DC3/DC4/DC5 Printer Cutters | Summa Standard Drag Knife Blade Holder #391-332 dia 1.5mm. | ||

391-163 Summa 55° Thick Materials Drag Blade Max thickness 0.80mm flexcut 0.80mm knife offset 0.90mm overcut 0.10mm | Summa F Series Flatbed Cutters Summa S2 D Series Vinyl Cutters SummaCut Series Vinyl Cutters SummaSign/SummaSign Pro D Series Vinyl Cutters | Summa Thick Materials Blade Special Holder #391-363 | ||

391-358 Summa 55° Thick Materials Drag Blade Max thickness 0.80mm flexcut 0.80mm | Summa F Series Flatbed Cutters Summa S2 D Series Vinyl Cutters SummaCut Series Vinyl Cutters SummaSign/SummaSign Pro D Series Vinyl Cutters | Summa Thick Materials Blade Special Holder #391-363 dia 2mm | ||

391-231 Summa 60° Rhinestone Drag Knife Blade Max thickness 0.60mm flexcut 0.60mm knife offset 0.50mm overcut 0.50mm | Summa F Series Flatbed Cutter Summa S Class 2 D Series Vinyl Cutters SummaCut Vinyl Cutters SummaSign / SummaSign Pro D Series | Summa Standard Drag Knife Blade Holder #391-332 dia 1.5mm. | ||

Buy Knives for CNC Digital Cutting Systems

All of the CNC digital cutters listed above use special knives to make the cutting. Flatbed cutter tables usually have a modular configuration and can be used to perform different cutting and processing techniques depending on which tool is currently installed and which knife is mounted in the tool head.

Purchase knives from Sollex for these cutting tools:

- Drag knife tool

- Tangential / Kiss cut knife tool

- Single edge knife cutout tool

- Double edge knife cutout tool

- Heavy duty knife cutout tool

- V-Cut knife tool

- Electronic Oscillating EOT knife tool

- Pneumatic Oscillating POT knife tool

- Perforating knife tool

- Rotary knife tool

- Router / routing bits tool

- Creasing tool

If you are looking for a supplier of cutting consumables and knives for vinyl plotters and digital cutting tables from manufacturers such as Aristo, Atom, Esko, Kongsberg, Summa, Zund, Jingwei JWEI, Elitron, iEcho, Gerber, Mimaki Sollex can provide you with high-quality knives on time and at an exceptional price. We manufacture plotter and cutter knives from high quality tungsten carbide and with high wear resistance.

Here you can check our drag knives, oscillating knives, tangential cutter knives, vinyl cutter knives.

If you do not find the knife you need, please contact us by mail, as not all of our products are available on our website.

Sollex is a Swedish supplier of industrial converting blades and machine blades! We have cutting products with cutting-edge technology and performance that improve manufacturing and converting processes and solve problems. With the right knives and blades, you can get simplified maintenance, time savings and an improved end product.

You are welcome to contact us with your questions:

Company name: Sollex AB

Customer service and orders: order@sollex.se

Telephone: +4635–15 75 00

Address: Box 5161, 200 71, Malmö, Sweden