Defects in Rolled Products when Cutting on a Slitter Rewinder

Common problems associated with cutting, slitting, and rewinding machines and possible remedies

Content:

- Problem #1: Dust on roll edges

- Problem #2: Chips and nicks on top circular slitter knife

- Problem #3: Sides with annual tree rings or a target effects

- Problem #4: Rough or ragged roll edges

- Problem #5: Winding of cuttings into rolls

- Buy knives and blades for slitter machines

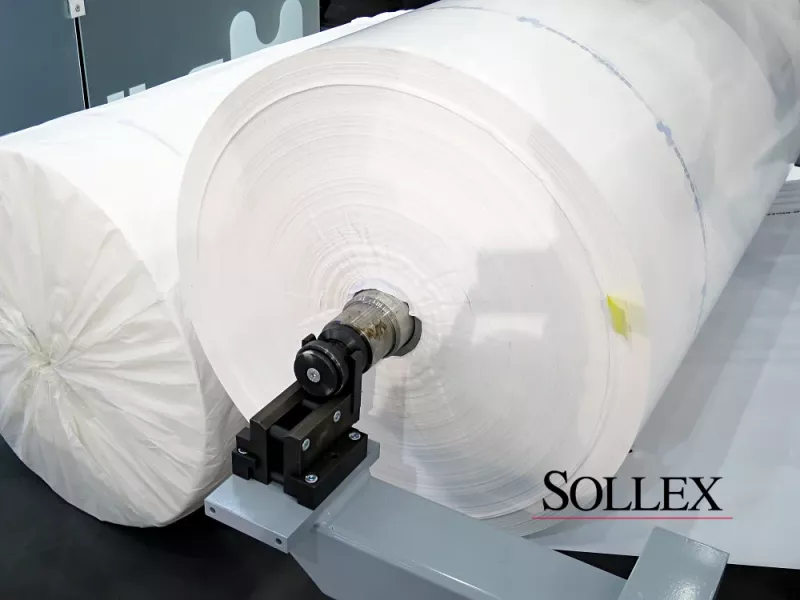

Flexible packaging manufactures face production defects regarding the material cutting and winding onto reels and rolls. In this text we will try to review the five most common and challenging roll winding defects and possible solutions for these problems.

You can also read our article "13 common problems when slitting and cutting blown film, and what you can do about them", in which we look at problems and defects in plastic film production

Problem #1: Dust on roll edges

Excessive dust during shear cutting on a slitter machine is a widespread problem for roll converting and most often caused by blunt top circular knives, damaged slitter bearings, or overspeed of the bottom slitter knives. When using circular top and bottom knives, blunt top knives or improperly sharpened top knives are most likely to cause dust formation. Parameters such as too much knife overlap or cutting angle should also be taken into consideration when minimizing dust. Finally, unstable blade guidance is a common factor for dust formation during cutting. Make sure that the blade  guides are fixed and sturdy to minimize dust generation.

guides are fixed and sturdy to minimize dust generation.

Problem #2: Chips and nicks on top circular slitter knife

Nicks and chips on the edges of circular slitter knives leads to roll defects. Chips and nicks on the dished top knife most commonly occur when shear cutting the position of the top knives over the bottom knives is set incorrectly or when the slitter blades are not in place correctly. Chips and nicks on the slitting knife edges cause small fragments of web to stick out beyond the edges of the winding roll.

Problem #3: Sides with annual tree rings or a target effects

Annual tree rings (also namned target effect) is a common roll winding defect on paper and plastic film roll sides. This defect in rolled products is very common on slitter rewinders and winders. Winding layer after layer of rough roll edge looks like absurd annual rings from a cut tree rather than a desired CD-disc. Again, blade edge friction and material type play an important role. Therefore, it is critical to have the right blades for the specific application.

Problem #4: Rough or ragged roll edges

Torn or ragged material edges are common roll converting defects when cutting with dull slitting razor blades when razor slitting a material web in a slitter. A blunt or burred blade alternately a blade with poor grinding will result in inferior cutting edges. Other reasons can be offset knives, blade vibrations or wrong web guidance. Too high lateral contact pressure or wrong shear angle are also reasons for poor material edges. The defect of ragged edges on roll or bobbin wound material can be corrected by changing the industrial razor blades to new ones. Alternately, a better blade with coated edges, applying an oscillatory motion to the blade, or repositioning the razor blade to get a new cutting point. Read more about razor blade slitting in our blog post Slitting Methods: Razor Slitting with Industrial Razor Blades.

Problem #5: Winding of cuttings into rolls

When winding the material edge on a roll it can be a problem if the winder cuttings are not collected in the cuttings removal system and follow the web into the winding roll. To avoid this defect, check that the air velocity at the inlet to the trimmer system is greater than the winding speed. Make sure that the laminator air flow is directed to the trimming nozzles. Check the guide edges of the unwind roller.

Buy knives and blades for slitter machines

If you are experiencing the above and beyond defects during the production and cutting of flexible packaging materials such as plastic film, paper, cardboard, aluminum foil, we can help you find a solution and deliver the knives and blades that will produce a high quality product with no waste.

If you are experiencing the above and beyond defects during the production and cutting of flexible packaging materials such as plastic film, paper, cardboard, aluminum foil, we can help you find a solution and deliver the knives and blades that will produce a high quality product with no waste.

Sollex has the widest range of industrial razor blades in Europe, allowing us to quickly and assuredly find the right solution for you. Our range of slitter blades can be found on our website. If you use circular shear cutting knives then write an email to our customer support with the required knife parameters and specifications and we will offer the right knife. If we have the right shear cutter knife in stock, it will be shipped the same or next day and the average delivery time will be 3-4 working days in Europe and 5-7 working days worldwide. Terms of ordering and delivery can be found here.

___

Sollex is a Swedish supplier of industrial knives and machine blades! We have cutting products with cutting-edge technology and performance that improve manufacturing and converting processes and solve problems. With the right knives and blades you can get simplified maintenance, time savings and an improved end product.

You are welcome to contact us with your questions:

Company name: Sollex AB

Customer service and orders: order@sollex.se

Telephone: +4635–15 75 00

Address: Box 5161, 200 71, Malmö, Sweden