Cut thin materials with Electric Oscillating Tool

Lessons learned from customer case

Looking at instructions for CNC and plotter knives for digital cutting systems, it is often clearly indicated which knife is best suited for a specific cutting application and material type. When it comes to cutting very thin materials up to 1mm thick, it seems that a type of cutting like kiss-cutting is appropriate. Given the design of the Z1 and Z2 knives, it makes sense to think that using these knives with a shallow depth of cut would be an option.

However, one customer of Sollex shared their experience cutting 1mm cardboard into coasters for glasses using a custom design. With kiss-cutting, the knife lasted for 800 coasters. When using Zund oscillating cutting tool EOT-250 with a Z60 knife, it lasted for about 8,000 coasters.

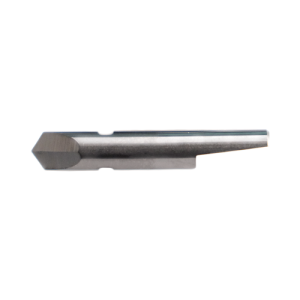

The Z60's tip wore down after 8,000 coasters, but the knife's full length remained unused and functional. To improve even further, the customer is trying the Z61, a knife with a similar design but without a tip. The idea is that instead of using the tip, the Z61 blade design makes small inserts while the EOT-250 holder oscillates the blade.