Slitting and Cutting Tape [Customer Case]

Slitting and cutting tape in a good way depends on several factors such as: the type of tape, the blade used, machinery settings, and the application the machinery is used for. This article is about Sollex findings for customers and our general recommendations of blades for slitting adhesive tapes.

Content:

- Types of tape

- Slitting and cutting in general

- Slitting and cutting tape with clean and sharp blades

- Avoid tearing

- 4 ways of industrial slitting and cutting tape

- Shear slitting tape

- Slitting tape with rotary circular knives

- Slitting tape with razor blades

- Toothed or straight machine blades for length cuts

- Converters case when slitting tape with razor blades

- Slitting adhesive tape with poor results

- Converters problems with standard razor blades when slitting tape

- Sollex razor blades with durability for slitting adhesive tape

- Sollex blades in customers slitting trials

- Recommendations

Types of tape

Tape refers to a versatile material with adhesive properties and flexible backing. Typically composed of materials such as plastic film, paper, or cloth, tape is coated with an adhesive substance on one side, enabling it to adhere firmly to surfaces. Its widespread applicability encompasses functions ranging from sealing and binding to masking and insulating.

Manufacturing processes for tapes involve applying adhesive substances onto backing materials for the specific requirements and properties of each tape type. Variations in adhesive composition, strength, and application methods cater to different industrial and commercial needs such as for manufacturing, construction, packaging, healthcare, and beyond

Manufacturing processes for tapes involve applying adhesive substances onto backing materials for the specific requirements and properties of each tape type. Variations in adhesive composition, strength, and application methods cater to different industrial and commercial needs such as for manufacturing, construction, packaging, healthcare, and beyond

Generally tape consists of a backing material, an adhesive material and optionally release liner. The most common materials used for tape include:

- Biaxially Oriented Polypropylene (BOPP)

- Polyvinyl Chloride (PVC)

- Polyester (PET)

- Polyethylene (PE)

- Paper

The adhesive is the sticky layer that allows the tape to adhere to surfaces. Common adhesives include acrylic, rubber, silicone, and hot melt adhesives.

A release liner is used in certain types of tapes, such as double-sided tapes, medical tapes and industrial tapes. The primary function of the release liner is to protect the adhesive surface until the tape is ready to be used. Usually release liner is made of silicone-coated paper. The silicone coating prevents the adhesive from sticking to the paper. Plastic films such as polyethylene (PE) or polyester (PET) are also used.

Slitting and cutting in general

Slitting means cutting a web material in its lengthwise direction. Cutting is the 90 degree opposite when a web is cut off into shorter pieces.

Slitting machines are the primary type used for cutting tape into smaller rolls. These machines can be further categorized into:

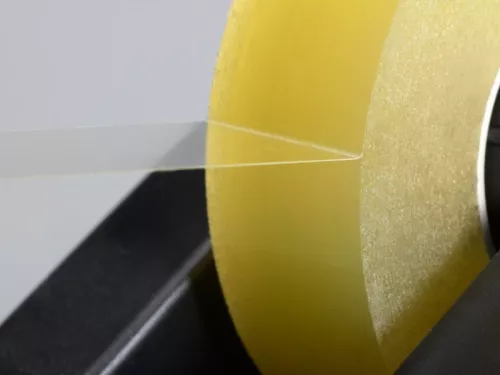

Slitting and cutting tape with clean and sharp blades

When slitting and cutting tape at adhesive tape slitting machine it is important to stabilize the tape to prevent it from moving. Stabilizing the tape ensures a straight and precise slitting and cutting process. Blades need to be sharp and clean. Dull blades lead to jagged edges and uneven cuts, which will strongly affect the final product, and taken to its extreme glues the tape together.

Avoid tearing

At all cost tearing must be avoided. Tearing leads to uneven edges and makes the material hard to work with. Tearing also leads to the tape fastening layer after layer and a severely damaged final product. Avoiding tearing can be done in the following ways:

- Using a cutting motion

- Using a 45 degree cutting angle towards the material

- Use finer or thinner blades

- Use better blades

4 ways of industrial slitting and cutting tape

The best method for slitting or cutting tape depends on factors such as: the type of tape, the precision required, and your machinery. There are in general 4 ways of slitting and cutting tape: shear slitting, rotary slitting, razor slitting and cross cutting.

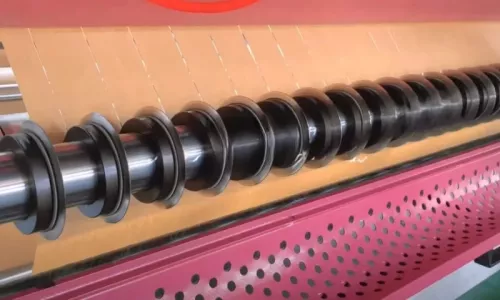

Shear slitting tape

Shear slitter rewinders utilizes specially designed blades that employ a shearing action to achieve straight slits, lowering the risk of tape adherence or uneven tearing. Shear slitting results in neater cuts compared to rotary or crush cutting methods. The main reason for shear slitting is the long durability of the rotating dished formed knife. Shear slitting is applied in industries requiring tape cutting, such as packaging, manufacturing, and printing, shear cutting gives accurate and clean slits.

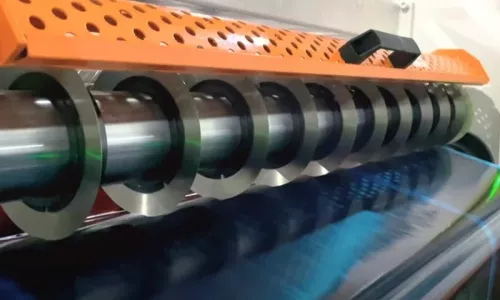

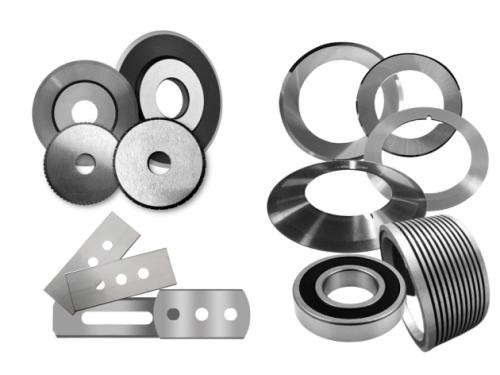

Slitting tape with rotary circular knives

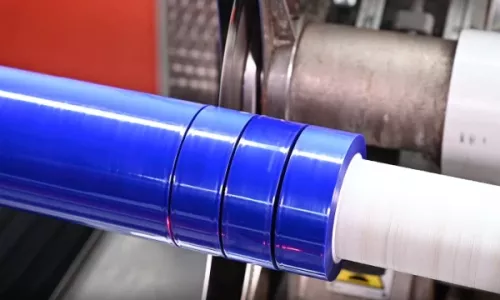

Rotary slitter rewinders use rotary circular knives to cut the tape. Slitting tape with rotary circular knives involves feeding a master roll of material into a slitting machine where rotary circular knives, positioned along the width of the material, cut it into the desired widths. These knives are mounted on rotating shafts and can be adjusted for different cutting widths.

The process begins with the material being fed into the machine, where the rotary knives make the cuts. The slit material is then rewound onto separate cores to form narrower rolls. These rotary knives, made from durable materials like high-speed steel or tungsten carbide, are crucial for achieving clean cuts. They work in conjunction with anvils or bottom knives, which provide a shearing action to ensure precision.

A critical aspect of this process is tension control. Maintaining the appropriate tension on the material throughout the slitting process prevents issues such as wrinkles or uneven cuts, ensuring consistent quality. This method is highly versatile and suitable for a wide range of materials, including paper, plastic films, and textiles, making it a staple in industries such as packaging, paper production, textiles, and adhesive tape manufacturing.

Rotary slitting offers significant advantages, including high precision, speed, and the ability to produce clean edges, reducing the need for further processing. Regular maintenance, such as sharpening the knives, is essential to maintain cutting quality and extend the lifespan of the blades.

Read also about log slitting with rotary circular knives in a "Log / Lathe Slitting Method Overview" blog post.

Slitting tape with razor blades

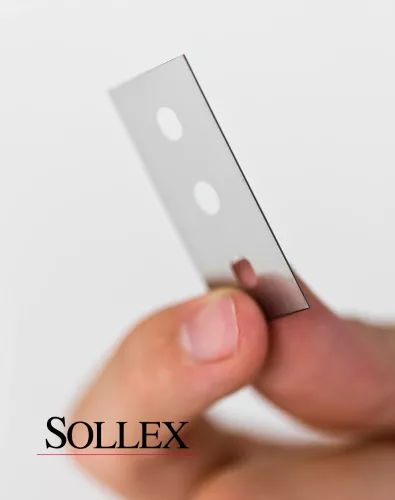

Razor slitter rewinders use industrial razor blades ( slotted razor blades, razor blades with 3 holes with straight or rounded corners) to cut the tape. This method is favored for its ability to cleanly separate tape layers without stretching or distortion. Razor blades are easy to install and modify.

You can use extra fine blades (0.13mm thick) to get next to perfect slitting and very clean cuts.

The only potential disadvantage with razor blades is lower durability compared to shear slitting. However, there are many different razor blades that provide different performance and durability. With the right razor blade you can have the same durability as with Shear slitting and still get a finer finished adhesive tape.

For the finest slits or cuts use razor blades.

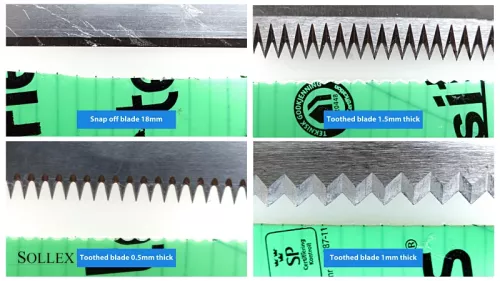

Toothed or straight machine blades for length cuts

Toothed blades are well suited for cutting across adhesive tape strips. The advantage of using serrated blades over straight blades is that there are multiple entry points into the material. This allows you to approach the material at a 90 degree angle of attack and make many small cuts in the material. However, straight blades are also often used for cutting tape or adhesive material in sheet form, e.g. when you want to cut it into small lengths without further winding it onto a roll.

In a machine this means that a smaller area is needed. When looking on the design of toothed blades there are four major things that affect its cutting abilities:

- Thickness

- Tooth angle

- Teeth width

- and Teeth length

The tooth design will determine the quality and shape of the cut material. Using toothed blades you will get at secreted cut or rather many small cuts. Blade thickness is important to get correct. A tough material needs a thicker blade and higher force to cut compared to a simple material. Teeth width determine how serrated the cut will be. Small teeth width gives a small wavy cut. Larger teeth width generates longer waves. But smother teeth gives almost straight cut.

Converters case when slitting tape with razor blades

The term "tape" serves as a broad categorization encompassing a diverse array of products. Professionals engaged in the manufacturing process are commonly known as tape manufacturers or converters which is when a tape is converted. Two converting methods are slitting and cutting. Adhesive tape is fabricated by applying an adhesive substance onto a plastic film substrate. This type of tape finds utility in various applications including double-sided adhesives, transfer films, and reactive adhesive systems. The precise application of adhesion facilitates efficient and accurate bonding of individual components, thereby enhancing overall product performance. A clean slit and durable razor blades are paramount for the production of adhesive tape.

Slitting adhesive tape with poor results

When blades are dull paper and other waste from the adhesive tape sticks on the blade.

When blades are dull paper and other waste from the adhesive tape sticks on the blade.

This waste material generates even poorer slitting results. A first recommendation is to make sure the blade is mounted with a 45 degree angle against the material web. Dull razor blades should be replaced before they make more harm to the finished product. A general guideline is to use as thin a blade as possible. There are several different blades and blade types optimal for slitting adhesive tape with or without paper. When just cutting adhesive and film the blade is not so abrasive. When the paper is added focus changes to optimize the paper slit and to avoid waste from the paper to stick in the adhesive.

Converters problems with standard razor blades when slitting tape

Sollex recently got two inquiries from two separate leading converters and tape manufacturers with high throughput operations. These converters complained about performance and durability of their standard razor blades. Customers complained:

"Our standard razor blades exhibit premature wear, that is why we want other blades with superior durability. Over production cycles, we have observed minor fraying on the paper surface of our materials."

"The materials traversed by our standard razor blades typically comprise white paper combined with black tape featuring a plastic backing. Our cutting operations often involve tapes with protective layers of either plastic film, paper, or are entirely composed of plastic or paper.”

Sollex razor blades with durability for slitting adhesive tape

In response to these challenges, Sollex provided the following general recommendations and testing suggestions:

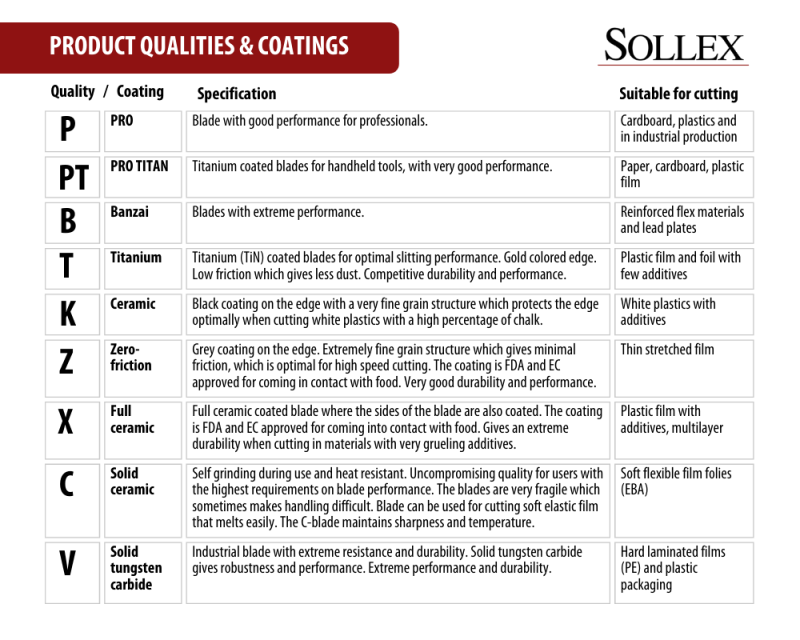

Sollex suggests usage of razor blades that are as thin as possible while still sufficiently robust to minimize vibrational interference during slitting processes. Many of our clientele engaged in paper label manufacturing benefit from razor blades equipped with Sollex K coatings. For applications involving films enriched with more abrasive additives, diverse color formulations, or scenarios where materials tend to adhere to blade surfaces, we recommend employing Sollex X coatings.

Specifically for the high-speed slitting of thin stretch films, we propose the utilization of type Z blades. Materials containing notably abrasive components, such as polypropylene (PP), are best suited to type V blades. Soft, abrasive materials like ethylene vinyl acetate (EVA) demonstrate optimal performance with type C blades. Types V and C are distinguished as our foremost offerings in terms of durability. While type C excels with soft and resilient materials, its delicate nature may render it excessive for labels and tapes.

"Nevertheless, in some cases we see operational challenges predominantly revolve around preventing material residues and additives from adhering to the razor blade, thereby impairing cutting precision."

To optimize the cutting of adhesive tapes, we recommend initial testing of the following blade types: 2-013-K, 2-020-K, and 2-020-Z. Should the thinnest option prove efficacious, we advise exploring alternative variants. Should you wish to proceed with trials of type V or type C blades, please do not hesitate to contact us. The V and C blades are available for purchase in packs of ten.

If you're looking for ways to improve your knife's performance, check out our article "4 Ways to Improve Slitter Knife Performance".

Sollex blades in customers slitting trials

Upon installation of the recommended inudstrial razor blades with 3 holes (2-013-K, 2-020-K and 2-020-Z), our client promptly observed enhanced performance relative to previously utilized disposable blades, which necessitated frequent replacement, in contrast to the enduring quality of the top performing Sollex blades.

Upon installation of the recommended inudstrial razor blades with 3 holes (2-013-K, 2-020-K and 2-020-Z), our client promptly observed enhanced performance relative to previously utilized disposable blades, which necessitated frequent replacement, in contrast to the enduring quality of the top performing Sollex blades.

Our first customer remarked: ”Among our operational staff, there exists some variance in opinions regarding the optimal choice among the three blade types. Typically, these blades undergo a trial period before adjustments to the blade holder's angle are made to achieve a renewed cutting edge."

"In conclusion, the slender 2-013-K blade type generally proves effective for cutting both film and tape. A thinner razor blade, devoid of vibrational disruptions, ensures a more refined cutting outcome. While further specific details would refine our recommendation, we currently propose that type 2-013-K represents an optimal choice for your tape cutting applications."

Recommendations

For slitting adhesive tape we recommend 2-013-K, 2-020-K, and 2-020-Z for further testing.

Remember to follow safety instructions provided by the tape manufacturer and the cutting tools, and exercise caution when handling sharp objects.

Sollex is a Swedish supplier of industrial knives and machine blades! We have cutting products with cutting-edge technology and performance that improve manufacturing and converting processes and solve problems. With the right knives and blades you can get simplified maintenance, time savings and an improved end product.

You are welcome to contact us with your questions:

Company name: Sollex AB

Customer service and orders: order@sollex.se

Telephone: +4635–15 75 00

Address: Box 5161, 200 71, Malmö, Sweden

![Konvertera och skära tejp [Sollex Kundcase]](https://cdn.starwebserver.se/shops/sollex-se/files/cache/slitting-and-cutting-tape-sollex-customer-case_grande.webp?_=1721913156)