Plastic Films Used for Solar Panels in Photovoltaic Industry

Photovoltaic Plastic Film: Solar Panels and Cells

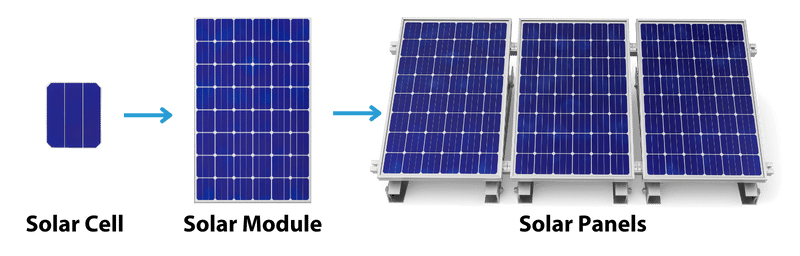

Special photovoltaic materials and devices are used to convert solar energy into electrical power. An individual photovoltaic device is called a cell, which produces about 1-2 watts of energy. To increase the power output of photovoltaic cells, they are connected in chains to form larger units called modules, which are placed between protective materials in the form of a combination of glass and plastic film to form solar panels.

Next, we will look at the role of plastic film in solar panel composition, the types of films and their features.

Role of Plastic Films in Solar Panels

Polymer films are widely used in the construction of solar cells. They are mainly used for encapsulation, backsheets and sometimes as front sheets in solar modules.

The photovoltaic industry mainly uses cast plastic films. Cast films compared to blown films provide better thickness control and fewer defects, which is very important for accurate and efficient encapsulation and protection required in solar panels.

The main function of plastic films in solar panels is to protect the solar cells from external factors such as UV rays, moisture, dust, temperature fluctuations and mechanical damage. For example, ethylene vinyl acetate (EVA) is commonly used as an encapsulant and polyvinyl fluoride (PVF) is used in panel backing sheets.

Some plastic films are designed to improve light transmission or reduce reflection, thereby improving the overall efficiency of solar panels. For example, face sheet materials such as fluoropolymer films (e.g., ETFE) are chosen for their transparency and resistance to clouding over time, ensuring that solar panel efficiency is maintained during the lifetime of the solar panel.

Films like polyimide are known for their excellent thermal stability, making them suitable for high-temperature applications. Moreover, these materials help maintain the insulation and electrical safety of the panels, preventing short circuits or electrical leaks.

What Solar Panels Are Made of

Solar panels usually consist of aluminum frame, tempered glass, encapsulant, solar cells (monocrystalline silicon or polycrystalline silicon), backsheet and junction box. Below we will take a closer look at the elements that contain plastic.

Encapsulant in Solar Panels

Encapsulant layers surround the solar cells to provide insulation and environmental protection. Encapsulants seal the cells in a transparent, adhesive material that bonds the glass on the front side and the backsheet. Thin EVA plastic sheets are inserted between the solar cells, front and backsheets and heated to 145-150 °C for about ten minutes to support EVA polymerization and to bond the module layers.

The main functions of an encapsulant are to protect the solar cells from moisture and environmental contaminants and act as an electrical insulator to maintain the safety and integrity of the panel's electrical connections.

EVA is the most commonly used encapsulant due to its excellent adhesion properties, transparency, and UV resistance.

Backsheet in Solar Panels

Backsheets are an essential component of solar panels, serving as the outermost layer on the backside of the modules. Their primary function is to protect the interior components of the solar panel, particularly the photovoltaic cells and electrical components, from environmental and mechanical damages.

Polyvinyl Fluoride (PVF) such as DuPont’s Tedlar® and Polyethylene Terephthalate (PET) are the most common materials used for backsheets.

Front Sheet in Solar Panels

Front Sheets are the protective layers placed on the top surface of solar panels, facing the sun. Their primary function is to protect the photovoltaic cells and inner components from environmental elements and allowing maximum sunlight to penetrate through to the solar cells.

Materials used as protective layers in solar panels are fluoropolymer films (ETFE or PVDF) and tempered glass.

Plastic Film for Solar Panels: Types, Applications and Manufacturers

Types of Photovoltaic Plastic Films

Each type of film is highlighted for its unique properties and the specific roles they play in the performance and durability of solar panels. Here’s a table with well-known brands associated with each type of plastic film used in the photovoltaic industry. Some films have specific brand names under which they are marketed, while others are produced by a range of manufacturers globally.

Type of Plastic Film | Properties | Applications | Manufacturer/Brand |

|---|---|---|---|

Ethylene Vinyl Acetate (EVA) | Excellent adhesion, transparency, and UV resistance. | Widely used as an encapsulant for solar modules | Widely produced by various manufacturers, ex. Sipchem, DuPont, LyondellBasell |

Polyvinyl Butyral (PVB) | Strong bonding, impact resistance, and UV blocking. | Used in building-integrated photovoltaics (BIPV) | Kuraray (Trosifol™), Eastman (Saflex®), Everlam, S-Lec (Sekisui), Mowital (Kuraray Europe GmbH) |

Polyolefin Elastomer Films (POEs) | Low processing temperatures, good mechanical properties. | Serves as an alternative to EVA for encapsulating solar cells | Dow Chemical (ENGAGE™ PV Polyolefin Elastomers), ExxonMobil (Vistamaxx™), SABIC (FORTIFY™) |

Fluoropolymer Films | Chemical resistance, high-temperature performance. | Used in front or back sheets | Chemours (Teflon™), DuPont (Tefzel™), Nowofol (NOWOFLON ET ETFE), Daikin (NEOFLON ETFE) |

Polyvinyl Fluoride (PVF) | Excellent weatherability, UV resistance. | Commonly used in backsheets to protect against environmental degradation | DuPont (Tedlar®), Krempel, Saint-Gobain, 3M etc |

Polyethylene Terephthalate (PET) | Transparency, durability, dimensional stability. | Often used in flexible solar panels and as a protective cover | Widely produced by various manufacturers, ex. DuPont (Mylar®), Teijin (Melinex®) etc. |

Polyimide Films | High thermal stability, good mechanical and chemical resistance. | Used in high-performance solar panels, especially in applications requiring durability at high temperatures. | Widely produced by various manufacturers, ex. DuPont (Kapton®), Kaneka (Apical™), Toray Advanced Composites, BASF SE, 3M, PI Advanced Material Co., Lonza Group Ltd, Kaneka, Taimide Tech. Inc., FLEXcon etc. |

Silicon-Based Films | Optimal transparency, resistant to high temperatures and UV exposure. | Employed in the top layer of solar panels to maximize light absorption and minimize reflection. | Widely produced by various manufacturers, ex. 3M, Cheever Specialty Paper & Film, Deku, DuPont, GASCOGNE FLEXIBLE, S.A.S., Industrias de transformacion de Andoain SA - ITASA, Momentive, Polyplex, Rossella S.r.l., Saint-Gobain Performance Plastics, Siliconature S.P.A. etc |

Ethylene Vinyl Acetate (EVA) Film for Solar Panels

Ethylene Vinyl Acetate (EVA) remains a prominent material in the photovoltaic industry, widely recognized for its beneficial properties such as high transparency, UV resistance, and excellent adhesive qualities, making it ideal for encapsulating solar modules.

Polyvinyl Butyral (PVB) Film for Solar Panels

Polyvinyl Butyral (PVB) is also significantly utilized in the solar panel industry, especially noted for its impact resistance and excellent bonding properties, which are crucial for safety in building-integrated photovoltaics (BIPV). The demand for PVB is expected to grow, particularly driven by its applications in clean energy generation like solar power.

Polyolefin Elastomer (POE) Film for Solar Panels

POE films are emerging as an alternative to EVA, offering potential benefits like lower processing temperatures and reduced potential-induced degradation (PID). Compared with EVA film, POE film has a higher water vapor barrier rate, weather resistance, and stronger anti-PID performance.

Fluoropolymer Film for Solar Panels

Fluoropolymer films are often used as front or back sheets in more demanding environmental conditions. Fluoropolymer film brands Teflon™ and Tefzel™ are known for their chemical resistance and ability to perform under high temperatures and are used in the front or back sheets of solar panels. DuPont Teflon ETFE and FEP fluoropolymer films can be used instead of glass in the frontsheet of solar modules. The films have great power output, are more lightweight and flexible than glass which offers durability and mechanical stability.

Polyvinyl Fluoride Film (PVF) for Solar Panels

Polyvinyl fluoride (PVF) film is often used in protective applications due to its excellent resistance to environmental degradation. One of the most notable brand names for PVF is Tedlar®, produced by DuPont. As a protective film, Tedlar® is often used on the backsheet of solar panels, where it prevents degradation due to UV exposure and weathering, thus prolonging the life and efficiency of the solar panels.

Polyethylene Terephthalate (PET) Film for Solar Panels

PET films, branded as MYLAR® and MELINEX®, are noted for their transparency, durability, and dimensional stability. In solar panels, polyethylene terephthalate films are likely used as part of the encapsulation layer or as a protective covering that must remain clear and stable to ensure efficient solar energy conversion.

Polyimide Films for Solar Panels

Polyimide films, notably DuPont's Kapton® series, are extensively utilized in the photovoltaic industry for their excellent thermal stability, mechanical properties, and electrical insulation capabilities. The Kapton® films offer enhanced durability and efficiency in photovoltaic modules by providing roll-to-roll processing capabilities and high thermal resistance, essential for maintaining performance in high temperatures commonly encountered in solar panel operations.

Silicon-Based Films for Solar Panels

Silicon-based films are used in the photovoltaic industry, primarily in thin-film solar cells. These films are valued for their good electrical properties. The usage of silicon-based films in solar cells align with the industry's efforts to enhance performance and reduce manufacturing costs while maintaining good energy conversion rates. Furthermore, advances in material science have allowed for the creation of thinner, more flexible silicon-based solar cells, expanding their application possibilities.

Industrial Razor Blades for Photovoltaic Industry

Sollex is a supplier of industrial razor blades and machine knives to the plastic industry worldwide. Sollex has years of experience supplying industrial blades and knives to manufacturers of blown and cast plastic film, adhesives and tape, textiles, packaging, graphics, medical technology, and many others. Our product range includes a large number of industrial blades, including those for plastic films used in solar panel manufacturing.

Our advantage is that with our extensive experience and well-tested blades with special coatings and grinding, we are able to choose the right blade for each case, so that you can get the right blade for each application. In addition, most of the blades on our website are in stock and are dispatched the same day if ordered before 13:00 or the next morning if ordered in the afternoon. With a warehouse in Malmo (Sweden) delivery within Europe takes about 3 working days and worldwide 5-7.

Looking for high quality blades for cutting PET or EVA cast film? Email us and we will find the right blades for your production. For some blades we are able to send samples.